Mark Albert Editor Emeritus

Mark Albert is editor emeritus of Modern Machine Shop Magazine. Mark has written about metalworking for more than 35 years. Currently, his favorite topics are data-driven manufacturing and global competitiveness. Mark’s editorial activities have taken him to numerous countries in Europe and Asia as well as across the United States many times. He is a graduate of the University of Cincinnati (Cincinnati, Ohio) and Indiana University (Bloomington, Indiana).

How Integrated CAD/CAM Transforms Inventions Into Products

The close connection between CAD and CAM is what links creative ideas to practical production for this unique custom manufacturer.

Read MoreGive Job Shop Digitalization a Customer Focus

Implementing the integrated digital technologies and automation that enhance the customer's experience should be a priority for job shops and contract manufacturers.

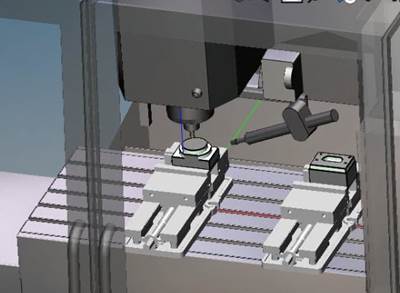

Read MoreGenerating a Digital Twin in the CNC

New control technology captures critical data about a machining process and uses it to create a 3D graphical representation of the finished workpiece. This new type of digital twin helps relate machining results to machine performance, leading to better decisions on the shop floor.

Read MoreWhen a Lathe With Live Tooling Rivals a Multitasking Machine

This shop is working its way up to a full-fledged B-axis multitasking machine. Meanwhile, turning centers with a Y-axis and live tooling are doing just fine.

Read MoreThe Strategic Value of Machine Tool Flexibility

This aerospace and defense supplier has a strategy to take advantage of the flexibility in its newest and largest five-axis gantry-type machining center.

Read MoreDigital Twins Give CNC Machining a Head Start

Model-based manufacturing and the digital thread enable Sikorsky to reduce lead times by machining helicopter components before designs are finalized.

Read MoreX-Ray Part Scanning as a Dimensional Measurement Process

Data-driven manufacturing gets a boost with a new class of x-ray inspection equipment that outputs a digital twin of a machined part, including complete 3D representations of internal and external dimensions.

Read MoreWorkshops for Warriors Is a Blueprint for Success

The founder of this training program for military veterans sees it as a pattern for rethinking assumptions and attitudes about the skills gap in U.S. manufacturing.

Read MoreThe Case for Automatic Door Operation

Automatic door systems for stand-alone machine tools require periodic inspection and maintenance, but excel in environments with automation capability or frequent door use.

Read MoreShifting Toward Preparedness and Flexibility with Turning Tool for Steel

The pandemic has taught manufacturers to reevaluate their preparedness for unexpected and drastic market disruptions. A practical example from a cutting tool manufacturer may show the way.

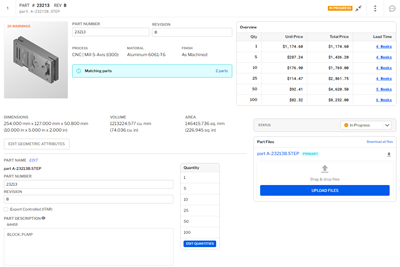

Read MoreLet’s Finish Closing the Quoting Gap

Sharing accurate, timely and actionable data is the key to an effective, respectful relationship between a machining job shop and the subcontracting finishing shop. Software that streamlines the quoting process can make this happen.

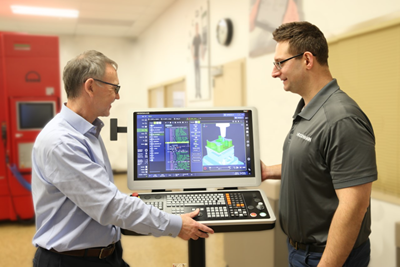

Read MoreMazak Takes Entry-Level Machine Tools to New Heights

A new machine series aims to address the immediate and longer term requirements of job shops by lowering cost barriers to acquiring manufacturing technology without foregoing capability or compromising performance.

Read More

.jpg;maxWidth=300;quality=90)