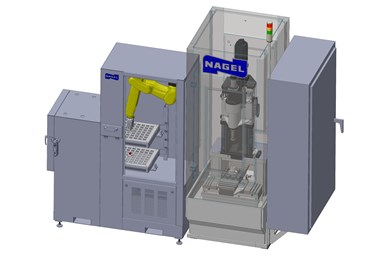

Nagel RL-2000 Robotic Loader Handles Secondary Operations

Nagel Precision’s RL-2000 robotic load system performs secondary operations to achieve lights-out manufacturing.

The RL-2000 robotic load-unload system from Nagel Precision Inc. is capable of performing secondary operations, which the company says could aid manufacturers in achieving lights-out manufacturing. Ethernet and Profinet communications systems inside the FANUC controller eliminate the need for expensive standalone controls, and the system integrates with old and new CNC- and PLC-based machines.

While traditional automatic machine tending and pallet systems are solely dedicated to loading and unloading, with separate systems for deburring, stamping, gauging and otherwise refining parts, the loader can perform these secondary operations. It is compatible with front- and side-loading applications. The operator opens the interlocked safety door, manually unloads as many as four finished trays and loads green trays. Operators can pull out the trays like drawers on heavy-duty-rail mounts, as can the robot during operation. Once each tray is complete, the robot returns the tray and pulls out the next, with sensors preventing crashes and ensuring that trays are in place. The robot can drop a finished part into a SPC chute at regular intervals for offline inspection. It can also use optional automatic gripper changers for rapid changeover.

The heavy-duty system is said to meet stringent automotive OEM specifications. The company offers customization to suit individual requirements and delivers the system turnkey.

Related Content

-

Niche Work If You Can Get It: A CNC Machine Shop Crafts Its Own Destiny

The latest innovations in metalworking aren’t always related to CNC automation or robotics. For Rosenberger North America, a 2022 Top Shops Honoree, it is the company’s niche processes that create the biggest successes.

-

Choosing a Five-Axis Machine Tool With Automation in Mind

While much focus is placed on the machinery that moves parts, the features most important for automating five-axis machining are arguably found in the machine tool itself.

-

Modern Bar Feeds Bring New Life to Automatic Swiss Lathes

Cam-actuated Swiss lathes are still the fastest way to process many parts. By adding modern bar feeders, this shop has dramatically improved their utilization with the ability to work unattended, even in a lights-out environment.

.png;maxWidth=300;quality=90)