Fineblanking Picks Up Speed

A fineblanking press from Feintool Technologies promises to bring the benefits of fineblanking to a wider range of small components.

A fineblanking press capable of 200 strokes per minute is rewriting some of the longstanding guidelines about the applicability of this specialized press-forming process. This development from Feintool Technologies promises to bring the benefits of fineblanking to a wider range of small components for which high production rates and low production cost may not have made this process favorable in the past. The use of an innovative direct servodrive, combined with a new hydraulic concept to control the distinctive triple-action motions required of a fineblanking press, is the basis for this advance.

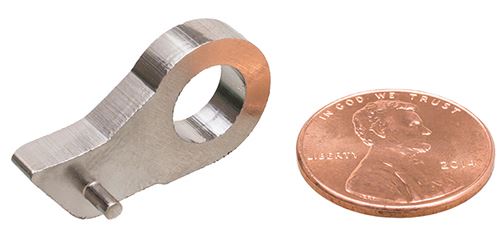

The fineblanking process involves specially designed tooling and a multistep operation of the press. The process avoids the shearing and fracturing of edge surfaces that is typically experienced in conventional blanking. Fineblanked parts are characterized by smooth, straight edges that most often require little or no finishing. Fineblanked parts are flat and have no rounded corners along the top of the side edges.

Fineblanking tools differ from conventional blanking tools by having much less clearance between the punch cutter and the lower die plate. A raised V-ring on the upper guide plate grips the feed strip at the initial closing of the tool. This action prevents the strip material from flowing in any direction except into the die opening as the cutting punch and ejector close onto the strip and then force the material into the die opening. In the final press motion, the cutting punch and ejector separate as they retract so that the completed part is freed from the blanking tool.

In essence, the forming action of the fineblanking press is not unlike an extrusion process, hence, the smooth edges on the side of the part. To add to the flexibility and capability of this process, the guide and die plates of a fineblanking tool can have additional forming features that create bosses, shallow contours and raised projections on the top and/or bottom of the part at the same time the blanking occurs.

Despite these benefits, one drawback of fineblanking has been the speed of the process. Production rates for fineblanking have been generally been slower than conventional blanking. Feintool Technologies’ new XFT 1500speed press, however, is capable of production rates that change that perception of this difference.

While any comparison to production rates of a conventional blanking operation can be misleading because it is difficult to adequately factor in important considerations, the XFT 1500speed can be meaningfully compared to the fineblanking press models that it replaces in Feintool’s lineup. For example, the new press has double the output of the GKP 100 or 160 series and the MFA 1600 using existing tools.

In fact, with high-speed tools specially developed for the maximum stroke rate of the new press, its output can be triple that of the MFA 1600. Early tests also show that manufacturing costs and investment costs per part are correspondingly lower in this model-to-model comparison, the company says. Savings in energy consumption and press maintenance are lower as well. In short, the enhanced capability of the new press makes fineblanking more economical for small batch sizes.

What sets apart the new press and enables it to perform 3 strokes per second (and as high as 200 strokes per minute) is its direct servodrive. The company says this is the first direct servodrive used in a fineblanking press. This drive replaces the gearbox that normally connects the servomotor and eccentric drive. Because eliminating the gearbox makes speed reduction unnecessary, the servo motor does not have to rotate faster than the top rate intended for this press (200 strokes per minute, in this case). Because motor rotation speed is slower, its mass inertia is smaller, thereby enabling a more dynamic response for precise programmed control.

Movement settings such as acceleration, intermediate stops and part removal can be defined to an accuracy of 2 milliseconds, the company says. Most importantly, braking distance can be as short as 2 mm to protect the tool from damage in an emergency stop.

Finally, the company has developed peripheral equipment designed to accommodate high-speed operation. These include systems for coil handling, pre-blanking, part removal and part handling. In addition, Feintool is exploring alternative production and tooling concepts to further leverage the possibilities of high-speed fine-blanking operation.

Read Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)