Nick Pinkston and Jeremy Herrman were used to being told they were crazy by the time their startup CNC machine shop, Plethora, attracted its first customers. Not that they were ever offended. Given their software backgrounds and their youth (both are now in their early 30s), they say they fully expected reactions ranging from “It can’t be done” to “Just who do you think you are, anyway?” upon telling industry veterans about an idea to fundamentally change how a generalist, contract machine shop operates.

Recent growth proves Plethora’s founders are anything but crazy. Revenue, reportedly measured in seven figures, expanded six-fold in 2017 alone, while the staff grew from 34 to 70 people. That was the shop’s fourth year of operation and “the first year we really started selling,” Mr. Pinkston says. What’s more, he and Mr. Herrman insist they’ve only just begun. Operating in an 18,000-square-foot space just a few miles from downtown San Francisco, they describe Plethora’s overall goal as making ordering machined parts as easy as ordering a pizza.

More specifically, they aim to make hardware as easy to iterate as software. In the latter arena, new features are deployed as they’re developed, sometimes even automatically. This continuous drip of improvement is a radical departure from the days of scheduled, all-encompassing updates. By achieving the same thing with the manufacturing of physical products, Plethora aims to speed prototype iterations and make it faster, easier and more affordable for more people to translate ideas to reality. “A lot of the coolest technology being developed today is basically just software with a body,” Mr. Pinkston says. “We have to get better at making the bodies faster.”

The principal barriers to quick turnaround aren’t the costs associated with keeping the lights on, nor with buying or maintaining equipment. As is the case with many machine shops, the primary expenses are human. And yet, there are no robot arms or other obvious forms of automation reducing labor on the shop floor. It’s all behind the scenes. “When you’re doing low volumes and one-offs, unit cost and machine time are not going to be your most significant costs,” Mr. Pinkston explains. “Even the people out on the floor aren’t going to represent your most significant costs. The biggest expense is programming your machines. That’s where we’ve chosen to focus our automation.”

Created through collaboration between machinists and on-staff mathematicians and other PhD holders, this automation consists in part of complex software algorithms that choose and apply tool paths to solid models automatically. This back-end system is linked directly to front-end automation at the interface between the customer and the digital factory. Whether through the web or within the customer’s CAD system, this software analyzes designs and provides instant feedback on manufacturability and the price to deliver by the customer’s chosen date.

Just as robots free human hands, Plethora’s end-to-end software automation is designed to free human minds, both from CAM programming and from front-end tasks associated with quoting and negotiating design issues. The result, as Mr. Herrman puts it, is “instant pricing and parts within days.”

Checking Assumptions

Like the founders’ tendency to draw inspiration from companies like Facebook—which, as Mr. Herrman points out, might release a few hundred “micro updates” on any given day—Plethora’s business model is a product of their experience.

Both are avid tinkerers. They met in 2008 as fellow enthusiasts of the maker movement, a do-it-yourself inventor culture that’s spawned collaborative “maker spaces” filled with 3D printers, desktop machine tools and other accessible manufacturing technologies. However, their backgrounds are mostly in software. Mr. Herrman formerly worked as a developer, and Mr. Pinkston previously founded another business driven by custom software. Rooted firmly in the concept of manufacturing as a service, CloudFab plugged customers in to a large, geographically disparate network of injection molding and additive manufacturing operations.

For Plethora customers, the front-end experience is similar. In this case, however, there’s no cloud-based network of suppliers standing ready to machine the parts. Rather, designs are evaluated and pricing is determined based solely on the resources on the shop floor. That’s for good reason. “You can’t make other people change how they do things,” Mr. Pinkston says, recalling the frustration of trying to deal with cost or delivery overruns without being able to connect with anyone involved in production. “Amazon Prime didn’t get to where it is today by having dollar stores fill the orders,” he points out about the popular subscription delivery service. “It got there by having its own warehouse.”

Automation can be so much more than following a repetitive script that never changes. Software can be a lot more flexible.

– Jeremy Herrman, Plethora founder

CloudFab was sold in 2012. As for Plethora, the founders say approaching the manufacturing industry as relative outsiders proved to be a key advantage in setting up their own “warehouse,” which of course in this case is a self-programming machine shop. In particular, they say many manufacturers don’t seem to grasp the full potential of automation. “It can be so much more than following a repetitive script that never changes,” Mr. Herrman says. “Software can be a lot more flexible.”

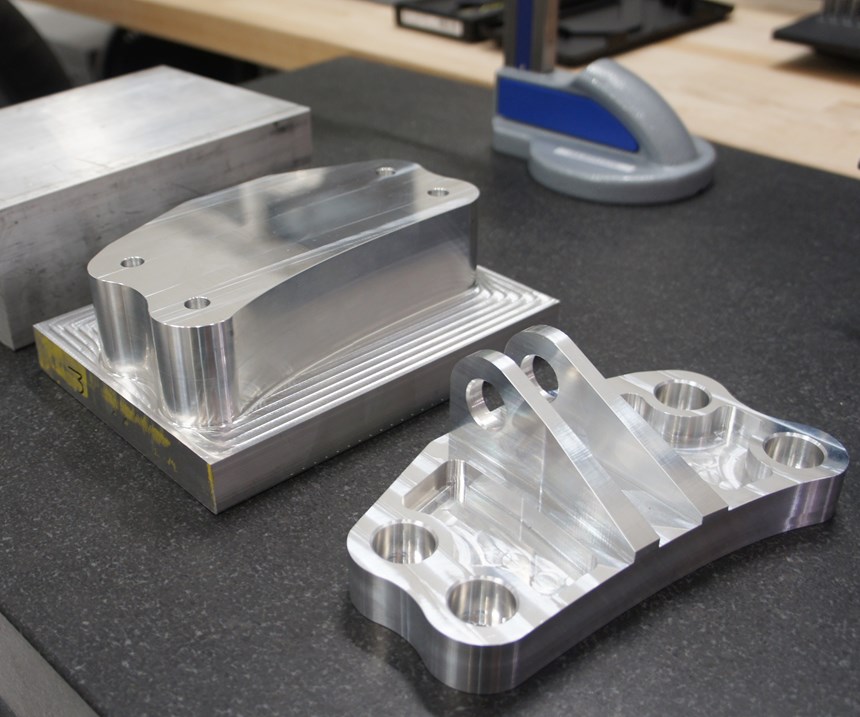

That said, they say they now have a much better understanding of why some balked at the prospect of automating CAM programming, a task that involves complex decision-making and many variables. Indeed, there are limits to Plethora’s automation. Three- and five-axis machining of complex geometry is generally no problem, but feature tolerances tighter than ±0.005 inch tend to demand the traditional CAM programming skills of the shop’s most seasoned machinists. Tolerances are available to ±0.001 inch, depending on the part, but the shop doesn’t dabble in compound geometries, and turning was in the beta phase at the time of this writing. Programming the coordinate measuring machine (CMM) is still a manual exercise. Certain work still requires traditional quoting and design for manufacturability (DFM) analysis on the front end as well. In fact, most jobs require humans in the loop at some point.

That said, most parts—nearly 90 percent—also lend themselves to at least part of Plethora’s software automation. Perhaps more importantly, that figure continues to increase as more “smarts” are built into the system. During the six months prior to this article being written, the shop had achieved a 24-percent reduction in average CAM time on all shipped parts. As far as Mr. Pinkston and Mr. Herrman are concerned, such progress thoroughly discredits warnings that a generalist machine shop focused on one-offs and low volumes can’t be profitable these days. “Some people seem to see things as, ‘Exceptions exist; therefore, it’s not possible,’” Mr. Pinkston says. “We reject that kind of thinking.”

End-to-End Automation (and Digitalization)

In another break from traditional thinking, Plethora’s founders say it doesn’t matter that their automated tool paths don’t necessarily provide the most efficient machining strategies for any given part. As long as workpieces can be machined to specification, reducing the time required to get them onto the floor in the first place makes more of a difference. That’s certainly been the case for the costs of running the business. “Cycle time is not the majority of lead time,” Mr. Pinkston points out about the shop’s priorities, adding that installing a new machine is easier and less costly than finding someone capable of programming it.

Software automation begins with an analysis system that uses feature recognition to identify specific geometry. Plugging into Plethora’s database of tooling, workholding, parameters and other digitized process information, it compares these findings to the shop’s capabilities and limitations in real time. It returns a color-coded part model indicating areas that can’t be machined, as well as areas that could potentially be machined more cost-effectively with a design change. Feedback typically takes less than two seconds through the web uploader, and Plethora engineers stand ready to step in on request. Pricing is on a sliding scale, based on the shop’s own costs as well as the customer’s chosen time to delivery. The fastest option (depending on the part and the shop’s constantly updating capacity model) is 3 days.

Lessons from Mr. Pinkston’s experience with CloudFab continue to filter into the development of this front-end software. “Everyone wanted instant quoting directly inside of CAD,” he says about one of Plethora’s earliest goals. The company achieved that goal two years ago with the release of a free, downloadable CAD add-in that puts a virtual version of Plethora’s factory at users’ fingertips. More specifically, there’s no need to transmit or translate anything for DFM feedback and pricing. It’s all available with a single mouse click from directly within the CAD program interface. The add-in expanded last year to include NX and Solid Edge CAD systems from Siemens in addition to the original offerings of Dassault Systemes’ Solidworks and Autodesk’s Inventor. Plans are in the works for additional file formats. Meanwhile, the Web uploader supports STEP, IGES and various other formats.

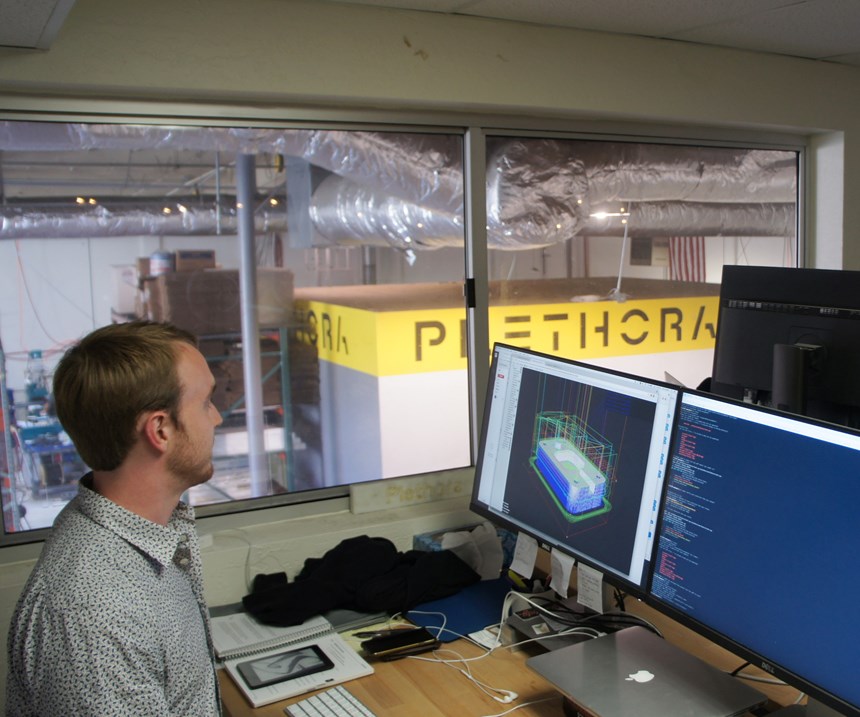

Determining the best machining method for each feature and the order of those operations—the strategy for machining the part—is a more complicated task than distinguishing holes from slots. Fed directly by the front-end design analysis, the back-end Plethora Production System features an interface that looks very similar to what customers see. In this case, however, 3D model color-coding denotes not whether the part is manufacturable on Plethora’s shop floor, but the extent to which programming can be automated. For instance, yellow indicates that the system can handle only a portion of the work on a part feature (say, only the roughing), whereas red denotes the need for full manual programming.

Green areas of the model are left fully to the algorithms written by the shop’s doctorate-degree holders, whose expertise ranges from mathematics and abstract number theory to graphical engineering and physics. In general terms, these algorithms are designed to leverage essentially the same process of elimination that would occur in a human programmer’s brain. The first step is determining the best gripping orientation for the part (which, in turn, informs the choice of workholding). From there, as Mr. Pinkston puts it, “features become sets of options, and the system prunes those options down to the best ones.”

He cites the example of a simple through-hole, which is approachable from two directions. Determining the best approach vector requires first plotting all possibilities for how all other features on the part can be machined. After all, certain options for other features might impede the drilling, and vice-versa. Informed by repeated simulation cycles, the system adjusts the program automatically until it arrives at a strategy for cutting the entire part to specification.

Universal Foundations

Whatever their inclination to upend traditional thinking about machining parts, most machine shops don’t have PhDs on staff. Nonetheless, many that have been covered in this magazine over the years are already in a good place to take the first steps toward implementing a similar system. Lean practices like 5S and the use of shadow boards; machinable vises and quick-change workholding; rigorous tool management; on-machine probing—Plethora’s founders emphasize that all this and more has been essential to making things work on the shop floor. Process standardization, which is beneficial for any manufacturing operation, is particularly important to maintaining the flexibility of Plethora’s software automation. After all, the system must “know” what it’s working with. Interchangeable workstations, and a digital library of fully defined cutting tool assemblies associated with best-practice, material-specific parameters, are just a few examples.

Scheduling the work is partially automated by another piece of the custom software, with work requiring less manual attention hitting the floor first. However, this system plugs directly into data stored and organized in the cloud via an ERP system that can be purchased (Plex), and that provides the kind of operational visibility that can be beneficial to manufacturers of all stripes. Even such practices as networking machines like servers in a data center (if only for basic monitoring), or using tablets to convey job instructions, are becoming more common. In short, Plethora closely resembles many other lean, clean machine shops, at least from the floor.

Keeping it that way during the past few years is a credit to the knowledge and input of seasoned machinists, the founders say. They add that the people who work on the algorithms also depend on these shopfloor veterans’ expertise, experience and instincts—the kinds of chops that don’t come with a university education. Indeed, one of the chief roles of Plethora’s project managers is to ensure that knowledge and lessons learned on the floor transfer from the machinists to the writers of the software. “Over the years we’ve been developing this, we’ve encountered a lot of different components—tens of thousands of unique designs—and we’ve just kept writing new geometric tests,” Mr. Pinkston says about the shop’s continuing work on automated programming. “Expert machinists are great at dealing with the subtleties that the computer doesn’t know exist. Then, over time, we capture their human behavior to improve our software system.”

As for mentoring the fresh talent that will be necessary to continue this practice, Plethora’s veteran machinists have computerized assistance. For instance, if an operator mounts a billet crookedly or loads the wrong cutting tool assembly, the system issues an alert as well as instructions for correcting the mistake. Such safeguards are intended to enable virtually anyone to load and unload the machines, learning and building confidence as they go with little risk of scrapping a part or crashing a spindle. Before long, someone hired for basic setup may well be able to contribute on a higher level—say, helping to ensure a part wall thin enough to buckle under tool pressure won’t be greenlit for automated CAM. “People who started out five months ago packing boxes are now doing programs for our five-axis machines,” Mr. Herrman says.

Accelerating Innovation

The word “plethora” means overabundance, an excessive amount. “We wanted to have a name that really implied how grand our intentions are, similarly to how Google is based on the number 10 to the 100th power,” Mr. Pinkston says.

This kind of thinking evidences the scope of his and Mr. Herrman’s ambition. According to most definitions of the “factory of the future,” production will occur in loops, not lines. That is, engineering will be hand-in-hand with production. Insights gleaned from part and equipment data at every node in the production cycle will drive design improvements and speed iteration cycles even as it keeps manufacturing processes on track. Plethora, however, strives for even more. “From a software perspective, we call that read-only,” Mr. Pinkston says about common definitions of the smart factory. “You’re just looking at stuff, and humans have to tweak everything.”

CNC made my grandfather a programmer; it didn’t put him out of work.

– Nick Pinkston, Plethora founder

What’s next—what Plethora’s self-programming factory represents—is the physical equivalent of continuous deployment, he continues. This is a software-industry term that describes the leveraging of cloud computing to update a piece of software immediately and without human involvement. In fact, he and Mr. Herrman say broader trends are already pushing the industry in this direction, citing the general push for more automation, greater process digitization and more built-in smarts. To whatever extent their particular business mode catches on, they see expanded opportunity for everyone in a future of compressed product development cycles.

This opportunity encompasses more than just the hypothetical Plethoras of the future, which would face little threat in low-labor-cost competition and few barriers to expanding capacity beyond the cost of new equipment. It includes more than just engineers and product developers, who may one day be able to iterate as fast in the physical space as the virtual space. It also includes the workforce of the future. Their opportunity is likely to be diverse, whether it can be found in developing software to support self-programming factories; applying traditional CAM skills at more specialized operations that remain better-suited for, say, medical or safety-critical aerospace parts; or integrating the robotics being credited for driving North American manufacturing competitiveness. “CNC made my grandfather a programmer; it didn’t put him out of work,” Mr. Pinkston says. “Machinists know metal and how it works. That will likely always be valuable.”

Plethora | 415-726-2256 | plethora.com

Related Content

Finally, A Comprehensive Software Solution Designed for Small Job Shops

Zel X from Siemens is an integrated software application that consolidates collaboration, design, manufacturing, and operations into a comprehensive, easy-to-use solution. From RFQ to delivery, it’s a more efficient way to handle quotes, manage jobs, make parts, and collaborate with teams of all sizes.

Read MoreTop Shop Builds Upon Employee Ownership for Future Success

In its quest to become the Fox Valley’s best-in-class employer, A to Z Machine has adopted an ESOP, expanded benefits and invested in apprenticeships.

Read More6 Tips for Training on a Swiss-Type Lathe

There are nuances to training a person to effectively operate a Swiss-type lathe. Derek Korn, Production Machining’s editor in chief, shares suggestions from a CNC machine shop.

Read MoreIf the Federal Government Is to Solve the Manufacturing Labor Shortage, it Needs to Start Here

Student-run businesses focused on technical training for the trades are taking root across the U.S. Can we — should we — leverage their regional successes into a nationwide platform?

Read MoreRead Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More

.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)