Why We Use Honing

A gear manufacturer describes the advantages it realizes by sizing and finishing bores through automated honing.

At our company, we use honing as an alternative to other hole machining processes for a variety of practical reasons, but also for one important philosophical reason. Forest City Gear has a philosophy for acquiring and retaining business called “Excellence without Exception.” It boils down to always giving the customer a higher level of quality than what the print or the customer’s instructions specify. Obviously, we want to do this without adding much cost or time to the job, and on bore-type gears, we have found automated honing to be a good, economical way to give the customer tighter control of bore size, roundness, straightness and finish. The customer notices the difference in a smoother, quieter, more efficient drive. Unless we stumble in some other aspect of the job, we will have a repeat customer. Other processes might deliver these same advantages, but the trick is to add this value without adding cost for the end user.

Gear Types

Forest City Gear’s principle products are fine- and medium- pitch custom gears such as internal, spline, sprocket, helical, spur and worm gears. Part runs range from one to several hundred thousand. Maximum OD is 20 inches on most parts, except for worms (5 inches) and worm gears (16 inches). Typical materials include 12L14, 1215, 4140, 8620, 9310 and various stainless grades as well as aluminum, bronze, brass, Inconel, Hastelloy, titanium, plastics, wood fiber and powder metal.About 30 percent of our work is aerospace-related, 5 to 10 percent is medical, 5 percent is military, and the remainder is industrial or instrument work. We have made parts for Boeing, Airbus, Cessna and Beechcraft as well as the space shuttle, the space station, Martian rover vehicles and the Abrams tank. We produce gears for several motorcycles and race cars, as well as one of the few bait-casting reels made in the U.S. Many of these applications demand high process capability where honing gives us critical advantages in control and consistency. In addition, we invest aggressively in training and the latest technologies to make our shop one of the most modern in the world.

Why Honing?

We have used honing since the inception of our business. We have tried hard turning, but we had difficulty controlling quality, especially for microfinishes. Another process, ID grinding, is good for gears with larger bores (greater than 0.75 inch) and low L:D ratios (0.5:1), but our range of work includes smaller diameters and relatively deep bores. In addition, ID grinding at L:D of 5:1 or more can cause deflection in the spindle, exacerbating taper issues. Honing, on the other hand, removes material faster than grinding as soon as you reach an L:D of 2:1. We still outsource parts for ID grinding, such as those with blind holes where counterbores leave no relief for honing tools.For our own shop, however, we found that precision ID grinding machines are more expensive than an equally capable hone. The crucial point is that accuracy for the grinder is dependent on the machine’s positioning capability while accuracy is mostly tooling-dependent with a hone. Periodic checks, calibration and refurbishing are needed to ensure positioning tolerances stay tight on a grinder. By contrast, honing tools are simple and rigid. When they wear, you replace them. And unlike a grinding wheel on the end of an arbor, the honing tool isn’t subject to bending forces. The tradeoff is that any given honing tool is suitable for only a very limited range of diameters, so you need to have more tools in stock than you would grinding wheels.

Two other points are worth noting about ID grinding and hard turning. If a part comes off a hone just a little too small, you can re-run it. This is more difficult with ID grinding. Also, neither process can produce honing’s characteristic crosshatch pattern on the bore surface. This is a desirable feature for maintaining an oil film for rotating gears.

The Impact Of Process Control

When working to high Cpk requirements, the high resolution of the tool feed system and consistent nature of the process give honing a real advantage in targeting and holding a dimensional sweet spot. This is critical because higher Cpk means the band of variability around your target values has to be reduced. For rule-of-thumb purposes, when the target is 1.33 Cpk, we shoot for about 60 percent of the print tolerance. At 1.67 Cpk, the target is 40 percent of tolerance. Thus a tolerance of 0.0005 on bore size shrinks to 0.0003 or less when Six Sigma quality requirements are imposed. Holemaking processes such as boring, drilling and reaming are capable of holding good tolerances, but when a high Cpk requirement is imposed, honing has the advantage in control and consistency. With automated honing, we can easily control tolerances to 50 millionths of an inch. In fact, we have run capability studies in which we’ve hit double-digit Cpk levels when honing for bore size.Producing A Bore-Type Gear

One of our core products, pump gears, start as flat, washer-type blanks made on a screw machine. These gears operate in a small precision housing, so any perpendicularity error in a shaft-mounted gear causes wobble, loss of efficiency, noise, increased friction and possible leakage. An adage of gear making is that a gear can be no more accurate than the blank from which you start. On a bore-type gear, this means starting with parallel faces and a perpendicular, round bore that has parallel walls and no taper or belling. Our minimum standard is 0.0005 inch for parallelism and perpendicularity, and we work to tighter tolerances as gear quality dictates.The pump gear blanks are double-disc ground for face parallelism and width. Then they are rebored on an automated lathe to requalify the perpendicularity. We intentionally leave some stock in the bore because we control final ID size and finish on a hone.

Pump gear blanks are usually stack-hobbed, grouped on an arbor in quantities based on the diameter of the bore and the face width of the part. Lack of good parallelism and perpendicularity can introduce lead error when cutting the gear, or force a reduction in the number of blanks on the arbor, eroding production efficiency.

Pump gears often have a standard keyway or a blind-hole keyway that must align with a tooth. When we cut that keyway, it throws up a tiny burr, and honing for final size allows us to clean up that burr, too. This is where honing really shines—it allows us to control final size down to a few microns. This kind of control is a real advantage when working to high Cpk requirements.

When To Hone

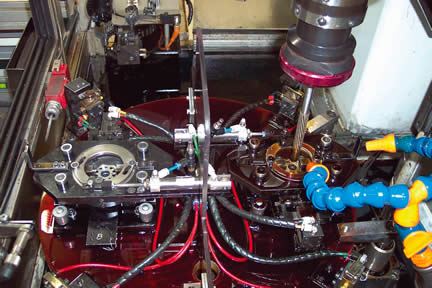

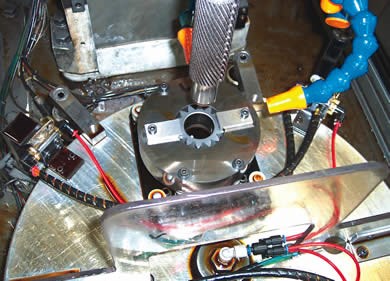

Depending on the requirements for specific gears, we hone gear bores at various points in the manufacturing process with three different systems from honing equipment supplier Sunnen. Parts are typically honed after hobbing, but blanks for extremely tight-tolerance gears might be honed both before and after hobbing. Fixturing on the hones allows some degree of control and correction of perpendicularity, should we need that. If parts are heat treated, they are honed afterward to correct for the slight shrinkage in bore size. And if there is a plating operation, removing a little plating from the bore with a hone is easier than masking the part for plating.We use CBN and aluminum oxide honing tools on these machines in several different configurations, depending on whether the bore is blind, keyed, etc. We get a tool life of about 250,000 parts, depending on the material, while typically removing 0.0020 to 0.0030 inch of stock at cycle times of 15 seconds. The hones can achieve a 16 microinch or better finish. Our newest system is a fully automated Sunnen SV-1005 vertical machine with a rotary table and automated part handling. Using Sunnen’s “Krossgrinding” tools, this machine can control hole size to accuracies of 0.25 micron with minimal variability. The machine can even make corrections that are not intuitive for an operator. Control features such as “correct for bore shape” allow the operator to select a “problem” bore image—“barrel” or “taper,” for example—and the machine will automatically correct the part.

No matter what the part print specifies, all

customers want quieter drives, smoother operation, greater efficiency

and longer life. We strive to give customers a product that is

noticeably better than one they would get from a competitor working to

the same spec. Honing is one way we add this value without adding

significant cost.Excellence Without Exception

This is the term we use to describe our formula for giving customers good experiences in every interaction with Forest City Gear. Here are a few key ways we implement that formula:

Invest in new equipment. We say we have the most modern gear making shop in the world, and we invest heavily to support that claim. We want to have the very latest technology so we can do things our competitors cannot. New equipment is arguably more productive and helps reduce lead times and costs. It is often more accurate, too. We invest 25 to 40 percent of our gross sales annually in new equipment, depending on our yearly performance, and we remain profitable. Aggressive technology investments also enable us to expand our range and give us unique capabilities, making us a preferred vendor in some niche markets.

Study other shops. We visit gear shops around the world and always bring back at least one good idea for implementation. I have been to shops in Germany, Switzerland, Sweden, France, Taiwan, New Zealand, China and Japan, to name a few. Most shop owners are proud to show you their operations. Our door is always open to competitors. We have actively courted U.S. gear makers to visit our shop and view our P&L statement, customer list and operations. We have had almost no takers, which is worrisome for our industry.

Train. We budget $100,000 to $200,000 per year for training a staff of 42, and this amount is spread across all employees. About 50 percent of our staff has completed AGMA basic courses, and our goal is to have everyone AGMA-certified. We want all our employees to understand our products and technology and be able to communicate intelligently with customers, even if just taking a phone message. We are very active in AGMA—our general manager once served as co-chairman of the education council.

Improve. “Continuous improvement” is as old as man. It is the thread that binds all the components of “Excellence without Exception.” It takes more than good price, quality and delivery to distinguish a manufacturer these days. We achieved AS-9100 certification about two years ago. Our quality rep is past chairman of the AGMA Statistical Council and a member of the Small Business and Educational Council. Lean manufacturing is our next goal. Though scrap in our shop is miniscule, we still see potential for cost savings and leadtime reductions.

About the author: Fred Young is president of Forest City Gear in Roscoe, Illinois.

Related Content

How to Reduce Cycle Times by 70% and More on Your Existing CNCs and Dramatically Improve Tool Life Too

By employing advanced high efficiency milling techniques for the entire machining routine, SolidCAM’s iMachining technology can drastically reduce cycle times while vastly improving tool life compared to traditional milling.

Read MoreUnderstanding G27, G28, G29 and G30

Take a closer look at these reference position commands.

Read MoreThreading On A Lathe

The right choices in tooling and technique can optimize the thread turning process.

Read More7 CNC Parameters You Should Know

Parameters tell the CNC every little detail about the specific machine tool being used, and how all CNC features and functions are to be utilized.

Read MoreRead Next

Machining And Racing

A visit to an automotive racing trade show revealed how some machining technologies are being applied to the production of hard core racing components.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More

.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)