Productive Machines SaaS Solution Prevents Machining Chatter

The Essential Optimization app makes machining operations more efficient by mitigating chatter vibration- and cutting force-related problems.

Productive Machines has announced its Essential Optimization, a specialized web application that prevents chatter vibrations and provides engineers with a simple-to-use solution to select optimum, stable spindle speeds and feed rates.

The Essential Optimization app, powered by Productive Machines’ machining dynamics algorithms, makes machining operations more efficient by mitigating chatter vibration- and cutting force-related problems. This new capability enables manufacturers to increase productivity, reduce waste and improve surface finish. This Software-as-a-Service (SaaS) solution is designed to assist manufacturers in making their processes more efficient without the need for installed software or machining physics expertise.

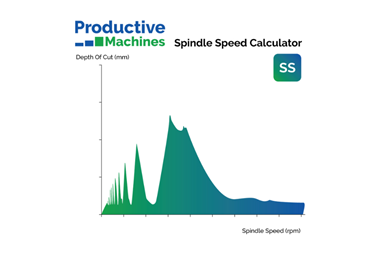

At its core, the Productive Machines Spindle Speed Calculator, part of the Essential Optimization app, relies on frequency response function (FRF) obtained through tap testing. Tap testing is a technique used to identify the structural dynamics of the machine tool assembly.

The Spindle Speed calculator uses FRF data to generate a stability lobe, a visual representation to determine the stable regions. This invaluable tool guides engineers in making informed decisions, ensuring a chatter-free milling process.

Key benefits of using the Essential Optimization app include: increased productivity by reducing cycle times and lead times to achieve more cost-effective machining operations; sustainable manufacturing by eliminating iterations and expensive prove-outs on machine tools that waste time, energy and materials; minimal tooling costs by mitigating chatter vibrations to minimize tool wear and save on tooling costs; quality assurance by producing parts with optimal surface finish and dimensional accuracy; and integration with the Feed Rate Calculator, enabling users to input chatter-free spindle speed and depth of cut values obtained from the Spindle Speed Calculator. This seamless integration optimizes feed rates by considering cutting forces, resulting in superior machining performance.

.png;maxWidth=300;quality=90)