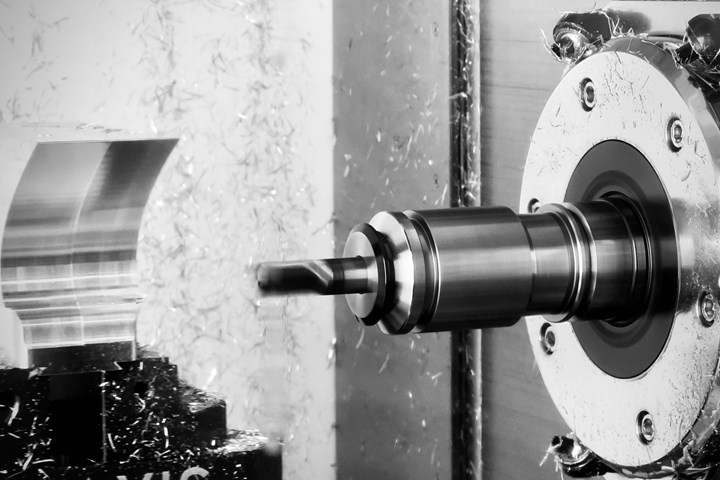

How Important is Spindle Power?

Consider these spindle attributes to make a choice that is balanced, usable and compliments your processes as best as possible.

Reader Question:

We are sourcing new machines as we head towards year’s end. As we narrow the list of candidates, we are stuck at a decision point between two machines, the biggest difference being the available spindle power. Half the team believes this is an important decision point, while the other half wants to focus on other attributes. How would you rate spindle power when it comes to evaluating a machining center?

Miller’s Answer:

As machines tools continue to evolve, there is an inevitability that they will become more difficult to discern. The iron structures that support these machines begin to look the same, and they offer the same tapers, with the same spindle ranges, with the same controller options. This is why I always advise shops to look beyond the spread sheet, into intangibles such as build quality, service, ease of automation and more. However, the spindle is indeed the heart of the machine and an important decision point that deserves its own deep consideration.

So, to answer the question: I rate spindle power as certainly important, but not nearly as important as other spindle attributes like taper, max rpm and construction (gear versus direct drive, preload type and so on). The problem is that sometimes these attributes often compete.

The spindle with high rpm usually has poor low-end torque, and the mega powerful geared head may be a detriment to your finishing operations. Even then, there are still several aspects you can analyze about the spindle power to make sure you are making a choice that is balanced, usable and compliments your processes as best as possible.

I’ve found that determining the real need your shop has for high spindle power is usually a common-sense exercise. If your shop does a lot of one-off prototypes, you probably do not have a need. Here, your machine time is primarily changeover and setup time, which no amount of spindle power can fix. I would focus on how the spindle compliments finishing operations. However, if you do steady work in one material, then you may find more power makes your processes more reliable and predictable over time.

The typical part sizes you do will also help settle this exercise. For example, if you regularly use 4-inch and larger face mills for roughing, then more power can make a process run smoother. If you do small parts and your largest tool is a ¼-inch end mill, then the tool will likely break before the spindle even registers a significant increase in needed power.

If this new machine purchase is going to be five-axis, then you may want to consider the toolholders you’ll need for these jobs. In the exercise of moving toward “done-in-one” setups, you may find most tool setups are much longer than they were on your three-axis, in which case the power is not usable due to chatter.

After you’ve determined a real need for more power, then the next task is to confirm the power and torque charts. Pay attention to the continuous and duty ratings. The continuous rating is important for long roughing cycles, while the duty rating may be what you need to push through a quick facing pass. I’ve seen machines from very reputable companies with impressive max power ratings on the spec sheet, only to find out that power is only available within a very narrow rpm band, and only for a 2-minute duty rating.

When analyzing the power curves, you will want to look for usable power in the rpm ranges you typically use. It may be low-end torque for steel and iron, or high-end power for aluminum. If you work with a broad range of materials, then the flatter the curve the better. You also want to confirm this with the type of tools and tool paths you use. Smaller tools using dynamic milling strategies utilize higher speeds, even in steels, and may also require top-end power.

Often overlooked is that the machine itself needs to be up to the task of supporting the cuts you’re asking the spindle to do. This means sturdy construction, good chip management to keep up with the volume and perhaps some thermal management to make it sustainable. Years ago, most machine builders constructed spindles specifically for a machine model. The structure was designed to support the cutting loads the spindle could produce. These days, machines are often of modular construction where a common spindle is used across several machine models whether it’s a five-axis VMC or four-axis HMC. This saves money in overall cost, but it may mean your usable power is less than anticipated for your model.

The conventional wisdom of yesterday where bigger was better no longer applies, even in hard metals. The tools, tool paths and more complex parts of today often require a more delicate touch. The biggest question to answer is simply “can we use this power?” By this, I mean you should have a real need for it, the power should complement the materials you cut, and it should be in a machine that supports it. If the above boxes are checked favorably for you, then buy with confidence. If not, then also buy with confidence knowing your other priorities are well covered.

Do you have a machining question? Ask the expert. John Miller leans on more than a decade of industry experience to answer machining questions from MMS readers. Submit your question online at mmsonline.com/MillersEdge.

Read Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)