3D-Printed Tooling Speeds Manufacturing of Cutting Tools

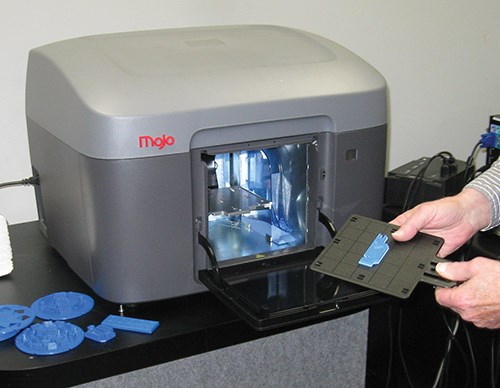

Knight Carbide's insert delivery times had to wait on custom tooling, so they acquired a Mojo desktop 3D printer from Stratasys make their own. Lead times for insert carriers were shortened from weeks to just six hours.

Share

It takes tooling to make tooling. For Knight Carbide, various fixtures, holders and carriers are needed to convey carbide machining inserts through the grinding and finishing operations required to make these tools. The cutting tool maker in Chesterfield Township, Michigan, primarily serves customers with specialized insert needs, and for every special tool design the company produces, new tooling for its own production process typically is needed to carry out the job. Waiting for this custom tooling to be delivered has historically been the largest contributor to Knight Carbide’s lead time. Now, lead times have begun to dramatically improve.

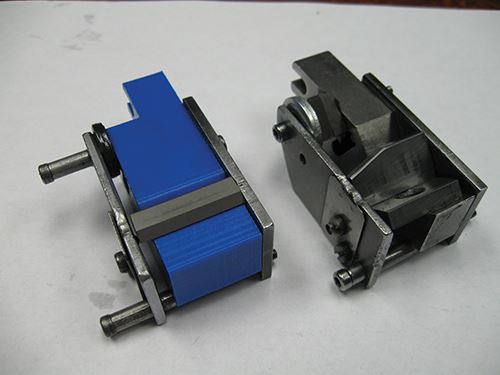

Edge prep carriers that used to be machined, but now are 3D printed, illustrate the reason for the change. One of these custom carriers could hold anywhere from eight to 30 carbide inserts for an abrasive edge prep operation, depending on the insert’s design and dimensions. Traditionally, a machine shop made these carriers, and Knight Carbide would wait 2 to 3 weeks to receive them. But the cutting tool maker wondered: Did these carriers really have to be made from steel? Or even metal? Through experimentation, the company discovered that a very durable plastic could also do the job. It learned this when it began to use a Mojo desktop 3D printer from Stratasys to produce the carriers in tough ABS plastic. In place of the multi-week lead time typical of the carriers, generating a carrier directly from a CAD model through 3D printing in this way requires a build time of only about 6 hours.

Moreover, the 3D printed carrier is often better than the steel one. When the parts were machined, developing complex carrier designs would have been impractical. Creating tooling to hold the inserts at precise orientations during the edge prep would have required five-axis machining and/or additional setups in order to machine the needed angles into the carrier. But 3D printing is unaffected by complexity—it simply prints a tangible model of whatever CAD geometry is provided. Thus, Knight Carbide has been able to fine-tune its edge prep operation lately by using carriers that hold the inserts at precise compound angles. As a result, not only has the lead time of the edge prep operation improved, but so has its capability.

The Mojo printer employs fused deposition modeling (FDM) to generate plastic parts that

are roughly equivalent to what might be made through injection molding. Solid plastic forms produced this way are easily durable enough for use as tooling—at least in many cases.

Knight Carbide Vice President Chris Kyle says there have been failures. An FDM linkage used in a workholding system for securing inserts rigidly proved too flexible to maintain the required clamp. Also, the hope of replacing customized steel fixtures in a twin-spindle surface grinding machine was not realized, because the heat of grinding in this machine was sufficient to melt the plastic. Mr. Kyle says the company is still exploring in this way, learning by trial and error to discover all that the 3D printer might do.

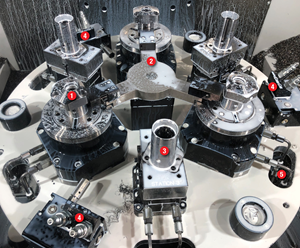

One other successful application that illustrates the potential for efficiency gain involves holders used for peripheral grinders, he says. In this application, too, an insert needs to be held at a particular angle as a particular feature is precision ground. Knight Carbide technicians used to create these custom-angled holders by hand, assembling the holders out of hardware available in the shop. Building one of these tools might take a skilled employee the better part of a day. But now, that holder geometry—precisely achieving whatever insert angle is needed—can be generated in the 3D printer while the skilled employee tends to other work.

3D printing is still new enough for the company that most of the production tooling is still the traditional steel. Going forward, Mr. Kyle sees the company systemizing and learning to rely more on the productivity gains the printer can deliver. In a way, the old, longer-lead-time process was easier to manage. Since insert production could not proceed until tooling arrived from the outside supplier, there was no choice but to wait. But now, the opportunity—as well as the challenge—is to leverage the new capability in order to respond more quickly. This will involve incorporating 3D printing of production tooling into the standard workflow.

“Six hours to build each edge prep carrier is fast compared to what we were used to, but it’s still a significant amount of time,” Mr. Kyle says. And typically there are multiple carriers for any given job. (The edge prep machine accommodates up to six of them.) Thus, the production process has to allow time for all of this 3D printing. Fortunately, though, edge prep comes late enough in the insert manufacturing process that—if the workflow is designed well—there ought to be plenty of time to let carriers be printed while carrying out other manufacturing steps.

In the meantime, Knight Carbide continues to find other uses for the printer. It has proven to be valuable for communicating with customers, Mr. Kyle says, because the company can now print a physical model of any new carbide insert design to let the customer confirm that the form of the tool is correct. Thus, while most 3D printing users start with prototyping and move later to functional parts, Knight Carbide has gone in the opposite direction. After investing in 3D printing to make functional tooling, the company now sees prototyping as an added source of value.

Related Content

SMW Autoblok Workholding, Automation Solutions Optimize Milling, Grinding Operations

IMTS 2024: SMW Autoblok presents the WPS XL for milling, measuring and grinding operations with five-axis and large part workpieces, as well as several products from its electronics and automation line.

Read MoreRoyal Products Introduces Versatile Three-Jaw Chuck

IMTS 2024: Royal Products features a Three-Jaw Chuck for CNC workholding, designed to reduce setup time between jobs and for the utilization of a range of top tooling.

Read MoreRevolutionizing Production: How Smart Hydraulics Drive 24/7 Manufacturing Excellence

All World Machinery Supply helps a firearms manufacturer up its game and improve and increase output.

Read MoreMachining Vektek Hydraulic Swing Clamp Bodies Using Royal Products Collet Fixtures

A study in repeatable and flexible workholding by one OEM for another.

Read More

.png;maxWidth=300;quality=90)