Medical Shop Performs Lights-Out Production in Five-Axes

Moving to five-axis machining enabled this shop to dramatically reduce setup time and increase lights-out capacity, but success relied on the right combination of workholding and automation.

Share

Five-axis machining has built its reputation in the metal manufacturing world through the many advanced machining strategies that are impossible without the additional rotational axes that set it apart. However, many manufacturers have found great benefits in 3+2-axis manufacturing techniques, using the rotational axes to reduce setup time. This approach can provide a firm foundation for highly automated machine cells such as the ones I found at Clippard Manufacturing, a Cincinnati-based valve manufacturer and machine shop.

Moving to Five Axes

CNC programmer Kyle Shearer operates the Haas UMC 500 SS. The five-axis machine tool dramatically reduced the need to set up secondary operations and enabled Clippard to perform lights-out machining on medical parts. Photo Credit: Chris Kern, Jergens

Clippard began in the 1930s as a manufacturer of radio parts. Its early claim to fame came during World War II, when it manufactured coils for the Allies’ radio-based proximity fuse — one of the most successful weapon technologies developed for the war. Over subsequent decades, the company pivoted to pneumatic valves for various industries, especially the medical industry. More recently, the company has also begun working as a contract manufacturer of medical parts, putting its experience meeting the exacting standards of the medical industry to further use.

The company’s first foray into heavy automation was in its fleet of 20 Swiss-type lathes, which found success working lights-out. Using this success, Manufacturing Engineer Alex Werdman convinced the company to invest in a five-axis Haas UMC 500 SS with a 16-station pallet changer to perform work that had been done on three-axis mills. The company made this investment with the intention of developing lights-out processes for the machine cell, but getting to that point meant investing in more than just the machine tool.

This 16-station pallet changer enables Clippard to run the five-axis UMC 500 SS unattended. The Jergens five-axis vises played a key role in designing this cell, as they enable the cutting tool to access as much of the workpiece as possible while eliminating the need for machining dovetails into every part. Photo Credit: Chris Kern, Jergens

One of the major draws of a five-axis machining was the ability to dramatically reduce setup time by machining multiple faces of parts in a single setup. According to Werdman, the move to the five-axis Haas made the jump to high-mix medical work much easier. “Being able to reach more faces of the part reduced the setup time for secondary operations by a lot,” he says. “Jobs that took 45 minutes per part on a three-axis were down to 27 minutes.” CNC Programmer Kyle Shearer agrees, saying, “I might touch a part 17 times before and only four times now.” However, this strategy relied on workholding that provided the cutting tool as much access to the part’s faces as possible.

At first, Clippard considered using dovetails, but after a conversation with Jergens representatives and distributors, the company opted for vises with modular jaws. “We thought we would have to use dovetails,” Werdman says, “but the vise has enough grip force and clearance to meet our needs.”

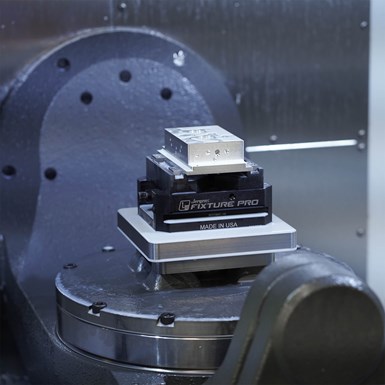

The Fixture Pro’s modularity is a major draw, as it enables the jaws to fit a wide variety of parts. In this image, the right side has a soft jaw in place, while the left side shows the wedge-shaped mount, which pulls down on the jaw as it secures it in place to increase rigidity.

The Fixture Pro system is a modular vise that can provide 3,500 pounds of clamping force while the minimal profile of the jaws can dramatically improve access to the part. This provides excellent rigidity for five-axis machining, with a variety of jaw options available to meet the grip and shape requirements of the part. “There are a lot of modular jaws that work right out of the box,” says Shearer. “And if we need a specific shape, we can machine our own jaws pretty easily.” While machining jaws takes time, it is still a major time saver compared to machining a dovetail into every single part for that job.

The vise is also self-centering to make it easier to consistently set up the workpiece for a job, and its jaws feature a quick-change design with no need for tightening. The jaw base connects to the top jaws using a spring system and a wedge-shaped mount. The combination of the spring and wedge pulls the top jaws down and back, firmly locking them into place and creating a highly rigid connection.

As far as Werdman was concerned, the benefits of the vise were clear. “It provided three things: faster setup, better clearance, larger options,” he says.

Lights-Out Milling

Of course, the long-term goal of the machining cell was to machine parts lights-out. In addition to investing in reliable workholding, the company installed in-process verification systems to detect tool wear and ensure part consistency. “We still need the CMM for paperwork,” Werdman says, but ensuring the machine tool is operating at its best at all times is still necessary for unattended machining.

The Jergens Fixture Pro vise provides excellent clearance to maximize cutting tool access without the need for dovetails. This benefit has enabled Clippard to implement 3+2-axis machining strategies to minimize setups and produce parts lights-out. Photo Credit: Chris Kern, Jergens

And did this work pay off?

“The Haas proved that five-axis machines were worth it,” Werdman says. “We could get 50 hours a month on the three-axis mills, and with five-axis we get 200-300 hours.”

The success of the Haas spurred Clippard to invest further in five-axis machining with a Matsuura MAM72-35V, intended to both increase the volume of parts the company could produce lights-out and improve the precision of its five-axis machining.

The Matsuura came standard with a 32-station pallet changer in a condensed footprint, dramatically increasing the capacity for lights-out machining. Like the Haas, it regularly puts in over 200 hours of machining time, mostly performing 3+2-axis machining. It can also pursue more aggressive machining strategies while maintaining the finish needed, as it can maintain a tolerance of ±0.0005 inches.

Despite being one of the major benefits of five-axis machining, this kind of dramatic increase in capacity and production speed is often overlooked by machine shops. Not all five-axis machines produce near-net shapes or large contours, and shops like Clippard have found great success thanks to careful consideration of the machine cell as a whole. “The people in charge needed convincing,” Shearer says, “but once they saw how much more we could get done and how quickly we could do it, they were on board.”

Related Content

Eight Articles to Understand Live Tooling

A roundup of the most read articles about live tooling on Modern Machine Shop.

Read MoreOrthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Read More10 Robotic Solutions You Can Find at IMTS 2026

Discover how today’s robots and cobots are making it easier than ever to automate tasks, free up skilled workers, and run machines unattended – even in small and midsized shops.

Read MoreShop Reclaims 10,000 Square Feet with Inventory Management System

Intech Athens’ inventory management system, which includes vertical lift modules from Kardex Remstar and tool management software from ZOLLER, has saved the company time, space and money.

Read MoreRead Next

OEM Tour Video: Lean Manufacturing for Measurement and Metrology

How can a facility that requires manual work for some long-standing parts be made more efficient? Join us as we look inside The L. S. Starrett Company’s headquarters in Athol, Massachusetts, and see how this long-established OEM is updating its processes.

Read More