AI Chip Flushing Keeps the Lights Out

Swiveling, camera-guided coolant nozzles solve a CNC machining automation problem that is ideal for artificial intelligence (AI).

Artificial vision isn’t just for robots. The latest machine tools from DMG MORI also employ high-performance cameras and artificial intelligence (AI) to guide “smart,” chip-flushing coolant nozzles and keep the workzone clean. John McDonald, general manager at the company’s Davis, California, development center, says this new system eliminates a hurdle to lights-out machining before a prospective customer even considers a pallet system or a robot. The machine itself solves the problem.

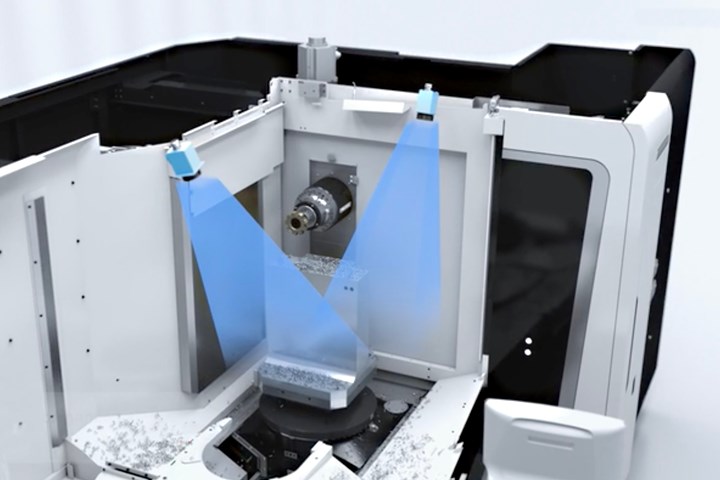

As depicted in this still of a DMG MORI animation, motorized, swiveling flush nozzles are guided by two cameras that image the workzone. AI determines where and to what extent chips have built up in different areas and, from there, how best to remove them.

The problem, of course, is the tendency for unholy tangles of coolant-soaked chips to gum up tools and fixtures. Although the AI system can’t be retrofitted — it requires a new machine — it certainly makes the sales pitch more compelling. For one, many experts have told me that the best AI is essentially invisible in that it works in the background, without much effort on the part of the user. That description applies to the chip flushing system. These ceiling-mounted nozzles swivel about automatically, guided by machine-learning algorithms that use high-resolution camera feedback to differentiate chips from coolant as well as the surrounding machine, fixture and part structures.

For another, AI is ideal for problems people either didn’t know they had or didn’t think they could solve. Based on McDonald’s testimony, this definitely applies to chip buildup interrupting unattended machining cycles. In fact, he says consultations about automation often begin the same way. “Say they have a turning machine,” he says. “We’ll stand and watch what’s going on — what’s the actual process? Well, the first thing they do is open the door, pull the nest of chips off the chuck, pull it out (and) blow the chuck off. That nest of chips hanging up there on the chuck? You can’t automate that (away),” McDonald says. “You have to figure out how to manage it.”

In addition to air blasts, some manufacturers have tried fans, he says. Others spin rotary B axes at high speeds to fling the chips away. Building flush systems into the machine tool is not a new practice either, and these systems add the benefit of eliminating the need for too much process engineering.

Generally, however, “spray and pray” goes only so far. After all, the whole idea behind many implementations of pallet systems and machine-tending robots is to swap different setups seamlessly. Chips accumulate differently with different parts and fixtures, and managing this accumulation is more difficult than managing, say, tool wear. “It’s fairly established how you do that,” McDonald says, citing laser tool pre-setters and in-magazine break detection capabilities. “But chips and coolant? This is the bane of the machine shop’s existence.”

With AI, this no longer needs to be the case. Water-repellent film and coolant/air blows keep chips and coolant from adhering to the two cameras, which take high-precision images of the entire machining chamber. The software that analyzes the camera feedback is capable of not only distinguishing where the chips are, but also determining the extent of the buildup. Depending on user-defined thresholds, it decides whether that buildup is sufficient to warrant cleaning, and, if so, how forcefully to eject the stream.

The spray itself follows one of multiple predetermined wash paths, depending on what camera feedback reveals about the most efficient way to clean off the current pallet or robot-tended setup. Users can also customize the path or make their own by simply dragging a finger across an image of the workzone on the touchscreen CELOS control interface.

The system is particularly useful for large machine tools, simply because there is more surface area to clean. However, McDonald says it can be just as useful on smaller machines that process not just a variety of different parts, but also a variety of different materials. For example, chip control will be very different when machining ceramic materials versus aluminum.

The system has a data-collection element, too. Analysis of past chip accumulation records — a task made easy by built-in graphical displays — might inform how to set the thresholds for different applications. This could be done for reasons other than ensuring efficient clearance. For instance, flushing might be delayed longer on one application than another, or perhaps using less force on one pallet can save coolant over time. Adjustments to cleaning criteria might also save energy.

This integration of AI into machine tools proves that data-driven manufacturing is not just for the high-level analysis associated with job scheduling or shop management. An operation like a basic coolant flush is a prime example. Before now, there was often no choice but to remove chips manually, or to expend time, fluid and energy flooding the entire workzone with coolant. Introduce optical data and AI, and coolant wash can be strategic instead of wasteful. Unattended machining remains uninterrupted machining.

Related Content

Shop Moves to Aerospace Machining With Help From ERP

Coastal Machine is an oil and gas shop that pivoted to aerospace manufacturing with the help of an ERP system that made the certification process simple.

Read MoreReinventing a Precision Shop With a Data-Driven Mindset

When this machine shop lost 90% of its business within three months, a reinvention was in order. Here's how it survived after quickly falling on hard times.

Read MoreWireless Couplers Work Wonders for Workholding

Possibilities range from individual control of chuck jaws and tombstone fixtures to more reliable robots.

Read More5 Stages of a Closed-Loop CNC Machining Cell

Controlling variability in a closed-loop manufacturing process requires inspection data collected before, during and immediately after machining — and a means to act on that data in real time. Here’s one system that accomplishes this.

Read MoreRead Next

Robots Get a Ride with CNC Machine-tending AGVs

Mobile machine tenders prove that “automation-ready” is a state of mind.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More.png;maxWidth=970;quality=90)

.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)