Alternate Coolant Delivery Method Made a Difference

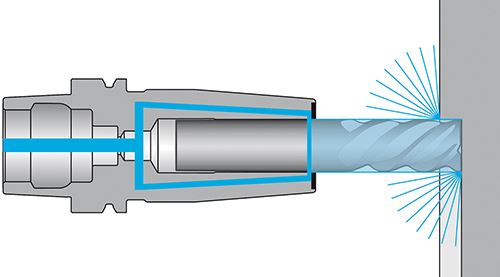

Haimer's Cool Flash toolholder delivers coolant through small slits to cover the entire tool circumference.

Matthew McGuire recently observed how changing only the method of coolant delivery could enable more effective machining of Inconel 718.

Prior to IMTS last year, Mr. McGuire, process development engineer for Makino, was optimizing an aerospace airfoil machining operation that was to be demonstrated at the show on a Makino multifunction G5 five-axis HMC. Originally, the process for the 45-HRc material used 12- and 6-mm solid carbide ball end mills for respective roughing and finishing operations. Because the tools didn’t support through-spindle coolant delivery, a hydraulic toolholder with a reducing collet was used to enable coolant to reach the tool tip. However, the tools only lasted one part with a cycle time of 60 minutes for each.

During a visit to the machine tool builder’s facility, Matt Frieden, regional manager for Haimer, suggested that Mr. McGuire try his company’s Cool Flash shrink-fit toolholder for this operation with no modifications to the cutting parameters. As a result of this single process change, tool life increased by 150 to 200 percent because of an increase in coolant volume delivered in a more targeted area, Mr. Frieden says.

Cool Flash offers an alternative to tools that do not accommodate through-spindle coolant delivery. Coolant is transported to the face area of the toolholder via internal bores in the chuck. A permanent cap on the face of the chuck leaves a narrow circular channel leading up to the tool. The coolant is collected in this channel and delivered through small, vertical intersecting slits, thereby distributing coolant over the entire circumference of the tool shank. This method of delivery not only increases coolant pressure where it is needed most, but more importantly increases coolant volume at the cutting edge by using centrifugal forces to prevent atomization.

According to Haimer, shrink-fit chucks with the Cool Flash option can be contracted and expanded as normal, while the stability, rigidity and interference contour of the original toolholder remain unchanged. Cool Flash toolholders are available in shank diameters ranging from 6 to 20 mm.

Related Content

-

Five Common Mistakes Shops Make with ER Collets (And How to Prevent Them)

Collets play a crucial role in the machining process, so proper tool assembly and maintenance is important. Here are five potential pitfalls to avoid when using ER collets.

-

IMTS Takeaways From the Modern Machine Shop Editorial Team

The first in-person IMTS in four years left the MMS editorial staff with a lot to digest. Here are a few of our takeaways from the show floor.

-

Big Daishowa Chuck Eliminates Chatter in Milling Operations

The Mega 12DS chuck is designed for trochoidal milling with anti-vibration end mills.

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)