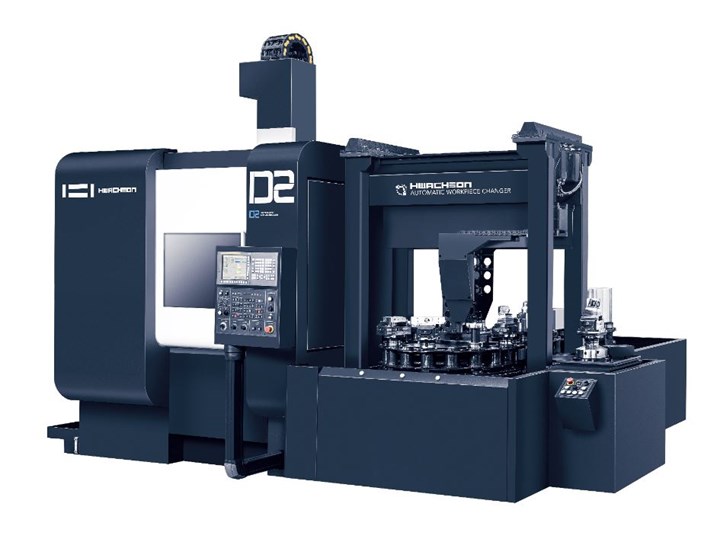

Automation Solutions featuring Hwacheon's D2-5AX and Automatic Workpiece Changer

In this digital demo, Jeong Hoon highlights many of the benefits the D2-5AX provides when machining complex shapes and parts. You will also learn how to maximize productivity during this inside look into Hwacheon’s automatic workpiece changer, the perfect solution for mass production.

The D2-5AX is Hwacheon’s best-selling 5-axis machining center and offers a variety of spindle selections up to 24,000rpm that can be customized based on your specific machining needs. In addition to customization, the Hwacheon automatic workpiece changer is an excellent solution for mass production. Allowing you to dramatically reduce set up times, the automatic workpiece changer is cost effective and efficient. The work set up station on the automatic workpiece changer is also separately configured from the machine operating area, allowing you to safely work even while the machine is in motion. Equipped with Hwacheon’s very own software package, including a scheduling system, your production team has the ability to manage multiple projects at once, increasing productivity.

For more information on this and other Hwacheon products, visit Hwacheon.com and follow them online on Twitter and LinkedIn.

Related Content

-

Digital Demo: X-Series CNC Machine for Extrusions

This unique fixturing system provides maximum hold with minimal clamping footprint to optimize spindle clearance and allow chips, debris and cutoffs to drop below the machining area and away from the spindle. (Sponsored)

-

Digital Demo: People and History Drive Solutions

Bourn & Koch has long provided unique manufacturing solutions. However, the people who work at Bourn & Koch enable the company to deliver value to each partner they work with. From service to assembly to engineering, each step builds on the solution—helping you solve your most challenging manufacturing problems. (Sponsored)

-

Digital Demo: Precision Engineering Meets Digitization

Whether it is presetting, shrinking, inspecting and correcting balance, or tool measuring, Haimer has created a modern digital tool room that can help manufacturers excel in today's competitive manufacturing marketplace. (Sponsored)

.png;maxWidth=300;quality=90)