Breaking The CAM Logjam

A manufacturer of metal stampings bridges the gap between generations of hardware and software.

Share

Leapfrogging in development of machine tools and CAM software poses a persistent challenge to metalworking firms. For example, when CAD/CAM programs first became available, the impact was felt immediately on the shop floor in the need for more complex machining operations. These elegant designs created a demand for more sophisticated machine tools that, in turn, require more extensive programming.

Machine shop managers recognize that shortcomings in either hardware or software can steer their manufacturing processes into blind alleys. While it's obvious that few shops can compete today without upgrading machine tools, a shop can face the same type of dead-end situation when new machine-tool controls are unable to communicate with existing CAM programs.

This is precisely the situation encountered recently by Acro Industries, Inc. (Rochester, New York), a full-service manufacturer of stamped sheet metal products for high-profile customers including Xerox, Eastman Kodak and Borg Warner. Customer demands made it necessary for Acro to increase its CNC machining capacity. As the two people responsible for developing the firm's tooling-production processes, toolmaker/technician Mike O'Donnell and customer support engineer Kevin Diedrick were given the tasks of procuring a new machining center and integrating it into the shop's operating system.

Finding A Solution

After considerable evaluation, Mr. O'Donnell and Mr. Diedrick purchased a VTC 250D/50 machining center manufactured by Mazak Corporation (Florence, Kentucky). In the process, however, they discovered that the SmartCAM part programs generated for the Fanuc CNC of Acro's existing machining center could not be transferred to the new machine's CNC.

"Mike and I knew ahead of time that we would not be able to post a code to the Mazak with our existing setup," says Mr. Diedrick. "Prior to setting up the new machine, we had a 3- to 4-week window to investigate our options for code generation." To their dismay, however, they learned that a man who previously had written custom posts for Acro was no longer available. They were also aware that technical support was no longer available for the SmartCAM software that their shop uses. The importance of solving this dilemma was heightened by the fact that Acro needed to maintain the schedules for its CNC machining centers to produce the dies necessary for manufacturing its finished parts.

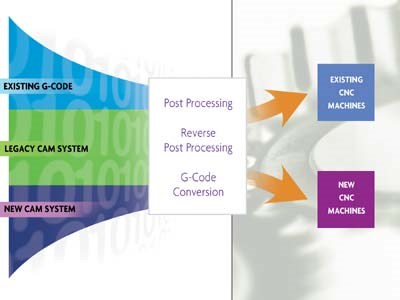

After conducting an Internet search for postprocessors, Mr. Diedrick discovered Intelligent Manufacturing Software, Inc. (IMS) of Haverhill, Massachusetts. IMS provides custom posts for individual CNC machine tools in addition to complete software packages. Acro selected IMSpost Version 7 that is the latest software package introduced by IMS. Typical of postprocessing software, this product transforms cutter location (CL) files into the specific G- and M-codes necessary to operate CNC machine tools. But what is more significant for Acro, the program also incorporates a reverse-post feature that converts legacy CAM programs into neutral, Automatically Programmed Tools (APT) files. These files may then be reposted to operate different machines. When linking to postprocessors via APT, therefore, a shop needs only a single post for each machine tool, regardless of how many different CAM systems are in use.

With regard to file compatibility, manufacturers face some important facts of life that APT's open architecture was designed to address. For example, many older CNCs incorporate slow processors with limited memory. If a part program can't be readily transferred to a faster CNC with greater memory capacity, a shop could be saddled with a time-consuming and inefficient process. In addition, because a large number of diverse CNC machines may be targets for the same part data, intercommunication may be complicated. Furthermore, as cutting tool geometry and machine motions become more complex, software must have the capability to define a larger number of parameters.

Providing Flexibility

According to Andy Brewster, vice president of marketing for IMS, the software provides Acro with important benefits. "First, it allows unrestricted movement of data from multiple CAM systems to any CNC machine tool. Second, it allows legacy programs to be used with new machine tools and without recourse to the original CAM program," says Mr. Brewster.

These capabilities enable Acro to continue using its existing CAM system at the same time that it begins its conversion to a Mastercam programming platform. "Everything we've done to date has been in SmartCAM," says Mr. O'Donnell. "This gives us the time to learn a new system while still being able to operate our business." In this vein, both Mr. O'Donnell and Mr. Diedrick are currently completing their training for the new system.

For a busy manufacturer like Acro, this affords the ability to phase-in the new CAM system without disrupting production. "We get paid for making chips, not for sitting in front of computers," says Mr. O'Donnell. The software also ensures that Acro's future decisions regarding machine tool purchases will be based strictly on how well a particular machine meets the company's needs. "We were limited to a custom post on specific machine tools and controllers for running certain parts," says Mr. O'Donnell. "Now that we're no longer tied to a specific controller, we have the flexibility to use any machine that we choose."

Flexibility is a critical factor for Acro because the firm's success is based on its reputation as a solutions provider that fulfills a wide range of customer needs. To this end, the firm maintains a 40,000 square foot assembly facility and a 10,000 square foot engineering facility in addition to its 70,000 square foot production shop. Approximately one-third of Acro's business involves manufacturing components for copiers. The firm also has the capability to test these parts and assemblies in house before shipment to its customers. Additionally, Acro provides remanufacturing services for copiers and other products. Another one-third of the firm's business involves manufacturing parts for automotive customers to which Acro is a tier-one supplier.

Geared For Mass Production

Acro's large array of CNC and conventional sheet metal fabrication machines includes a CL-707 CNC laser-cutting machine manufactured by Cincinnati Incorporated (Cincinnati, Ohio). This machine incorporates a double-pallet loading system, and it's used for rapid cutting of sheet metal stamping blanks. Acro also uses two Trumatic CNC punch presses manufactured by Trumpf Inc. (Farmington, Connecticut) plus a variety of press brakes and shears. In addition, the firm operates a large number of punch presses that range from 22-ton to 600-ton capacity.

Now that the new Mazak machine is in service, it's used primarily for higher-volume production, while the other VMC is primarily used to machine one-of-a-kind parts. By allowing part programs to be interchanged from one machine to the other, the postprocessor software simplifies switching machines when necessary due to production demands or periodic maintenance.

In terms of its impact on the shop floor, a key feature of the reverse post is its ability to translate the visual formats of part programs. Because machine operators become accustomed to working with a particular type of screen format, they are uncomfortable with changes in the layout or code designations on their CNCs. The reverse post allows screen formats to be tailored to meet operators' expectations. This is a very important factor that preserves the comfort level of key people and, consequently, reduces the potential for errors.

Meeting The Competition

In addition to hardware and software, long-term success in manufacturing depends on creating new processes that optimize productivity and quality. Acro's ability to prosper under a variety of economic conditions during the past 25 years is a tribute to the company's creative application of the best available technology. This commitment to new technology has been a persistent theme in the company's success since CEO Joseph Noto and executive vice president John H. Gefell founded the company in the mid-1970s.

A current example of this approach is a process Acro developed for manufacturing the tiny, metal shutter component that Eastman Kodak uses in its popular line of disposable cameras. The camera's operation depends on maintaining extremely precise dimensions for this stamped part. Although these delicate parts had previously been manufactured outside the United States, Acro secured a substantial amount of Kodak's business by developing a production process that satisfies its customer's strict quality standards and cost objectives.

In addition to successfully meeting the crucial challenges of quality and productivity, Acro's success depends on staying abreast of its customers' changing needs and priorities. As manufacturing functions are increasingly outsourced, supply chain issues become more complex and troublesome. Thus, major manufacturers increasingly gravitate toward vendors that can assume a wider range of responsibilities such as design, engineering and testing of product components. In machine shops both large and small, establishing a reputation as a problem solver has never been more important than it is today.

Related Content

10 Robotic Solutions You Can Find at IMTS 2026

Discover how today’s robots and cobots are making it easier than ever to automate tasks, free up skilled workers, and run machines unattended – even in small and midsized shops.

Read MoreContinuous Improvement and New Functionality Are the Name of the Game

Mastercam 2025 incorporates big advancements and small — all based on customer feedback and the company’s commitment to keeping its signature product best in class.

Read More4 Commonly Misapplied CNC Features

Misapplication of these important CNC features will result in wasted time, wasted or duplicated effort and/or wasted material.

Read MoreCan ChatGPT Create Usable G-Code Programs?

Since its debut in late 2022, ChatGPT has been used in many situations, from writing stories to writing code, including G-code. But is it useful to shops? We asked a CAM expert for his thoughts.

Read MoreRead Next

OEM Tour Video: Lean Manufacturing for Measurement and Metrology

How can a facility that requires manual work for some long-standing parts be made more efficient? Join us as we look inside The L. S. Starrett Company’s headquarters in Athol, Massachusetts, and see how this long-established OEM is updating its processes.

Read More