CAM Automation and Library Revitalize Precision Manufacturer

CAMWorks has powered TECMA’s transition to 3D digital CNC machining. The software’s optimizations have enabled the shop to tackle precision parts for space.

Sonia Susac is the second-generation owner of TECMA Inc. She spearheaded the shop’s transition to 3D digital machining and ensured it had the certifications and qualifications to continue providing precision parts for everything from carbon-negative energy systems to critical parts for the Artemis space missions. Images courtesy of TECMA.

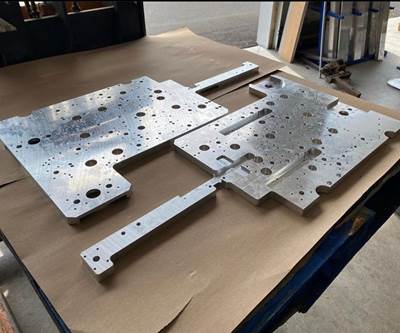

From the Apollo 11 lunar lander module to today’s Artemis missions, TECMA Inc. has long provided precision machining services for the aerospace and defense industries. The company has supplied parts for many U.S. defense contracts as well, and has recently expanded into producing parts for carbon-negative energy systems. The company specializes in CNC and conventional precision machining for hard-to-manufacture, mission-critical components, but this specialization has required evolution over the years.

The company was founded by Fred Schwarz and his partner Alfred Nohr in 1957. Schwarz led TECMA until his passing in 2012, after which his daughter Sonia Susac took ownership. She recognized that keeping the company competitive required a transition from 2D programming and manual machining to 3D digital production.

“When my father passed away and I took over management, I quickly realized that we needed to re-tool and modernize to continue to be successful,” Susac says. “While TECMA had and still has a great reputation in the aerospace and defense industries, we needed to expand our customer base and update our compliance to NASA and Department of Defense requirements. Part of that was to obtain some important certifications — such as AS9100 Quality Management Systems, ITAR [International Traffic in Arms Regulations and Export Administration Regulations], and cybersecurity compliance — in order to remain competitive and grow.”

A Manual Overhaul

When Susac inherited the company, it had only two CNC machines to nearly 20 manual machines. It also had a small employee base with only 2D programming experience. Investing in automated CNC machining centers with five-axis machining capabilities, as well as a software system to automate digital machining operations, would enable the company to compete for new business. CAMWorks met TECMA’s goals of modernizing, increasing efficiency and improving quality.

“The CAMWorks VoluMill high-speed machining module lets us reduce stress on the spindles and end mills while accelerating machining, helping us to control costs while increasing throughput,” production manager Singh says.

“In 2012, I didn’t want to see my father’s legacy disappear or have his employees lose their jobs, so I decided to manage the company to supervise the transition from predominantly manual machining to machining parts in the digital world,” Susac says.

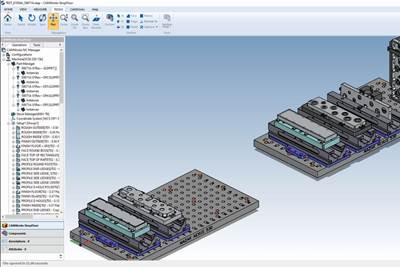

“We looked at many different CAM systems, but what really sold us on CAMWorks was the fact that the software uses the features from a SolidWorks CAD model, which is the gold standard we need,” she continues. “It provides automation for the programming of tool paths and the generation of G code.”

Production manager Tirath Singh speaks highly of CAMWorks’ performance with TECMA’s new CNC machining centers. He recounts benefits to communication, which have led to fewer mistakes and less scrap, as well as a boost to throughput.

Transitioning to 3D Digital Machining

Since transitioning to CAMWorks, the rejuvenated TECMA has bid on a wider range of parts while maintaining its flight-rated business. According to production manager Tirath Singh, the move to CAMWorks — in conjunction with the installation of three-, four- and five-axis machining centers — has enabled the company to boost efficiency and productivity while reaping a host of associated benefits.

“With CAMWorks, our throughput has increased substantially,” Singh says. “Now, it takes less time to set up a machine and we have much fewer jobs that need to be reworked. If there is a change to the model, the G code updates automatically. Our communication is better — you can actually see the part, simulate the tool path and see how it’s set up — which means that there are fewer mistakes and less scrap. The CAMWorks VoluMill high-speed machining module lets us reduce stress on the spindles and end mills while accelerating machining, helping us to control costs while increasing throughput.”

Building a Library of Expertise

Another reason that TECMA chose CAMWorks is the software’s extensive knowledge database function. With CAMWorks, the shop can record its experience and expertise in difficult machining operations for future use.

“We don’t typically run the same machining job over and over,” Singh says. “Nevertheless, there are machining operations on difficult features that can be re-used for portions of future jobs. We are invested in CAMWorks for longevity, and work daily to build up the technology database for the long term.”

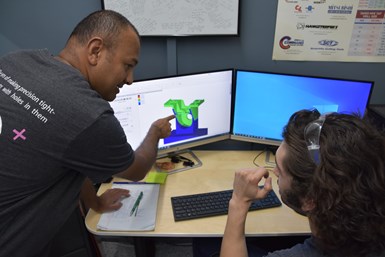

The capabilities of CAMWorks have enabled TECMA to form custom internship programs that grant local high-school students hands-on work at the company. The company’s dedication to training a new generation has quadrupled its number of machinists.

Training the Next Generation

TECMA’s transition from manual machining to 3D digital machining with CAMWorks has created opportunities for the company to work with local schools to initiate apprenticeship programs and train the next generation of TECMA machinists.

“When we upgraded our machines and programming capabilities, we encountered difficulties finding machinists,” Susac says. “At the same time, we were donating our old manual machines to local high schools to help them build their mechanical engineering and robotics programs. This helped us build relationships with the teachers and students to offer summer internships and eventually custom apprenticeships. We hired one of the summer interns, who is now going through our apprentice program, learning CAMWorks, and is already programming five-axis work. Not every 20-year-old can say he is making space propulsion engine parts on a five-axis! CAMWorks is an important spoke in the wheel that’s rejuvenating the company, and we have quadrupled our number of machinists as a result.”

Related Content

CNC Machine Shop Honored for Automation, Machine Monitoring

From cobots to machine monitoring, this Top Shop honoree shows that machining technology is about more than the machine tool.

Read MoreWeiler to Debut New Automation Features For Its Lathes

Weiler’s V 110 four-way precision lathe introduces features new to the U.S.

Read MoreZero-Adjustment Bar Pullers Simplify Turning Automation

Spring-loaded grippers and adjustable programming are enabling bar pullers to fulfill their promise to save time and money in CNC turning automation.

Read MoreUsing the Toolchanger to Automate Production

Taking advantage of a feature that’s already on the machine tool, Lang’s Haubex system uses the toolchanger to move and store parts, making it an easy-to-use and cost-effective automation solution.

Read MoreRead Next

Machining a Complex Part in a One-Man Shop

Feature recognition and efficient workholding let this shop cost-effectively produce an intricate part that was bigger than the machine tool's travels.

Read MoreIntegrated CAM Software Automates Data Transition From Engineering to Production

By switching to CAMWorks software, Decimal Engineering was able to boost its throughput and quality while saving time and money.

Read MoreCAM's Simulation Capability Boosts OEM's Spindle Uptime

CAMWorks and CAMWorks ShopFloor have boosted Anchor Danly’s spindle uptime by 15-20% through simulation and automatic G code updates.

Read More