Coming Soon: CAM and Cutter Integration

Four basic elements of a process for producing a CNC machined part are: (A) the machine tool, (B) the cutting tool, (C) the CAM software and (D) the inspection device.

Four basic elements of a process for producing a CNC machined part are: (A) the machine tool, (B) the cutting tool, (C) the CAM software and (D) the inspection device. A and B certainly work together, A and C get integrated via the postprocessor, and A and D are often integrated as well—because the probe might reside in the machine.

However, few people would put B and C together. That is, few think about how the CAM software and the cutting tool might complement one another more effectively.

Steve Bertrand, sales manager for Mastercam, says bringing these two elements together only stands to reason. Of the four elements above, the cutter and the software are the two that change the most quickly. These receive frequent upgrades; the others do not.

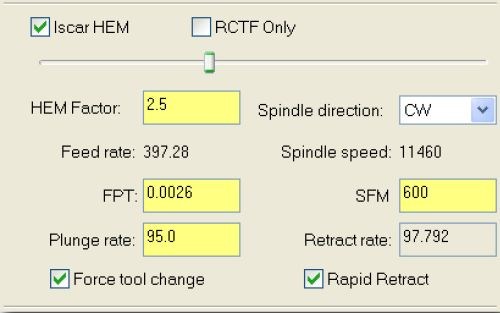

Soon, he says, CAM from his company and tooling from Iscar will be able to work together more effectively than perhaps any CAM and cutter combination ever has. Within Mastercam X5, a simple slider device will make it easy for programmers to obtain high-efficiency machining parameters that are tailored particularly to specific Iscar tools. High speed machining will become that much easier to implement. Read the full story here.

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)