Compact Handling Facility Sticks To Basics

Shops consider a number of factors when justifying automated parts storage systems, including cost, required floor space and machining application.

Share

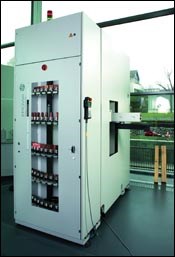

Shops consider a number of factors when justifying automated parts storage systems, including cost, required floor space and machining application. A clever use of configurable storage racks in place of rotating magazines keeps the design of Erowa’s Robot Compact handling facility simple and affordable for shops of all sizes. The racks are internal to the robot, so the system occupies little space on the shop floor and can get very close to the machine tools it serves. The robot is designed especially for manufacturers of small parts such as medical components and EDM electrodes.

The robot is most useful for shops that need immediate productivity improvements but can’t afford to spend time and money implementing larger, more complicated solutions, says Bob Byers, vice president of sales and marketing at Erowa. Increased customer demand, more exacting tolerances, new jobs involving geometrically complex parts—all these factors can drive shops to seek technological solutions for improving productivity. Often, however, purchasing the latest machine tools and other equipment isn’t always possible or even necessary, Mr. Byers explains. A more economical solution is to find a way to increase the productivity of existing equipment.

“In the era of ‘bigger, faster, stronger,’ we’re going back to a very simplistic approach with the Robot Compact,” Mr. Byers says. “Most people think they need a wholesale change in their shop, but sometimes tweaking one little area can increase profits. Starting out small with something very simple that can increase the productivity of the machine tool is huge.”

With that in mind, the robot is designed to be easy to install and operate. The racks used to store workpiece pallets are easier to change out than a rotary magazine system, Mr. Byers says. This allows shops to easily reconfigure the system for different applications. Moreover, with the racks mounted inside the system to the left and right of a small gripping arm, all movement is internal to the robot. This configuration keeps the robot’s footprint to 2 square meters and allows installation right next to machines with virtually no gap. Despite its small size, the Robot Compact features 160 pallet positions. It can supply one or two machines with pallets weighing 30 kilograms or less.

“This is something a shop can implement, make money from and see immediate benefits without a lot of investment in time and money,” Mr. Byers concludes.

Related Content

-

Ballbar Testing Benefits Low-Volume Manufacturing

Thanks to ballbar testing with a Renishaw QC20-W, the Autodesk Technology Centers now have more confidence in their machine tools.

-

Addressing Manufacturing Challenges with Automation

GrayMatter Robotics’ Physical AI robotic cells for manufacturing offer immediate impact and results.

-

4 Commonly Misapplied CNC Features

Misapplication of these important CNC features will result in wasted time, wasted or duplicated effort and/or wasted material.

-02.jpg;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)

-02.jpg;maxWidth=970;quality=90)