Consider L:D When Choosing A Lathe For Small Parts

Should shops always defer to Swiss-type lathes to process small, long and often complex parts? Not necessarily. As a general rule, a Swiss-type is most appropriate for machining workpieces with L:D ratios of 4 to 1 or greater. Parts with lower L:D ratios may be machined economically on turn-mills.

Share

When is a CNC Swiss-type lathe the most appropriate machine tool for the job? For years, these machines have been equated with high precision for efficiently machining small, complex parts. The reputation is well deserved. However, as these machines become more common, work is increasingly assigned to them erroneously. The distinction between work suited for Swiss and work suited for more straightforward turn-mill machines may not be readily apparent. In fact, Index Corporation believes the misapplication of Swiss-type technology is quite prevalent.

“Our studies have shown that between 70 to 80 percent of 1 1/4-inch work designated to Swiss machines could also be accomplished quickly and accurately on fixed-headstock machines,” says Olaf Tessarzyk, Index Corporation CEO.

Because a Swiss-type machine offers a means to quickly produce small, long and often complex parts in one handling, shops defer to this method for a broad range of small parts without fully exploring their options, he says. More important than the part’s diameter is often the part’s length-to-diameter ratio (L:D). As a general rule, a Swiss-type lathe is needed for pieces with L:D ratios of 4 to 1 or greater, he advises.

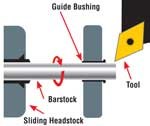

The trick to accurately cutting pieces within this L:D range is maintaining enough rigidity during the cutting process to minimize workpiece deflection. The Swiss-type machine pairs a sliding headstock with a guide bushing. The sliding headstock pushes the workpiece through the bushing during the cutting process. Z-axis motion comes from this; the tool doesn’t have to move. With the intended purpose of counteracting deflection, the guide bushing ensures that the cutting tool can remain as close to the collet as possible. By providing support across the entire length of the part in this way, the bushing helps deliver tight accuracies and fine surface finishes.

That said, parts with lower L:D ratios can be machined accurately without a guide bushing.

“In some instances, a shop can easily machine a short, 1-inch part without a guide bushing more economically than it would be able to with a Swiss-type,” Mr. Tessarzyk explains.

Many Swiss-type machine builders now offer an option of bushless sliding-headstock machines to accommodate lower L:D ratios. Another alternative is a fixed-headstock machine, such as a more general turn-mill. Index offers the C100 high-production turn-mill, for example. While still supplying the requisite rigidity to precisely machine small parts, this machine can address some limitations of a Swiss-type, one being its lower milling power. The turrets on a fixed-headstock design can supply more power for milling medical parts and various other jobs, Mr. Tessarzyk says.

According to Index, a machine such as this can also process certain parts more economically than can Swiss-types. Mr. Tessarzyk cites these potential areas for cost reductions:

Material Costs. To process parts in this diameter range on a Swiss-type, shops would typically need to purchase pre-ground material. The turn-mill can accept normal stock, potentially reducing material costs. In addition, the average user is actually consuming more material. There is more of a remnant because the spindle is behind the guide bushing and a certain amount of material is needed simply to reach this distance.

Maintenance Expenses. Each time that the guide bushing slides on the material, debris is created. Over time, the bushing can get dirty. Weekly maintenance is required to clean away the accumulation.

Setup Time. The vertical bed design (as opposed to slant) enhances accessibility to tools. The operator can reach the tools and change them out more quickly, thereby minimizing setup time. Meanwhile, the footprint is still as compact as a Swiss-type lathe.

Related Content

CNC Milling Tips & Tricks: 7 Articles For You to Mill Through

Dive into popular milling articles from Modern Machine Shop, Moldmaking Technology, and Production Machining to discover tips, tricks, and innovations that will make your chips fly—and your competition sweat.

Read MoreMachine Tool Drawbar Made With Additive Manufacturing Saves DMG MORI 90% Lead Time and 67% CO2 Emission

A new production process for the multimetal drawbar replaces an outsourced plating step with directed energy deposition, performing this DED along with roughing, finishing and grinding on a single machine.

Read MoreDN Solutions Technical Hub Promises Efficiency Across Operations

Efficiency cannot be achieved focusing on it only at a micro level; it must be addressed at organizational, shopfloor, and individual machine scales. Find out how DN Solutions is doing so from its recently opened Technical Center in Schaumberg, Illinois.

Read MoreSwiss Happens: 8 Swiss-Type Articles to Keep Your Skills Sharp

Learn the history of Swiss-type lathes, practical ways to implement these sliding-headstock machines in your shop, and much more in this collection of articles.

Read More