Consider Tool Capacity on Your HMC

Quick-change workholding made it plain that additional setup time savings would require a larger tool magazine.

Quick-change workholding made it plain that additional setup time savings would require a larger tool magazine.

How many tools can your horizontal machining center hold? Think carefully about this when you consider your next HMC. Get more tool capacity than you think you need. It might be easy to guess how many tools a job might require, but can you really imagine how many different jobs you might wish to keep set up for this machine one day?

Production Machine & Engineering of Madison, Wisconsin saw its needs change in this way. Having more tools on its HMC became valuable once the shop’s use of the machine became more efficient.

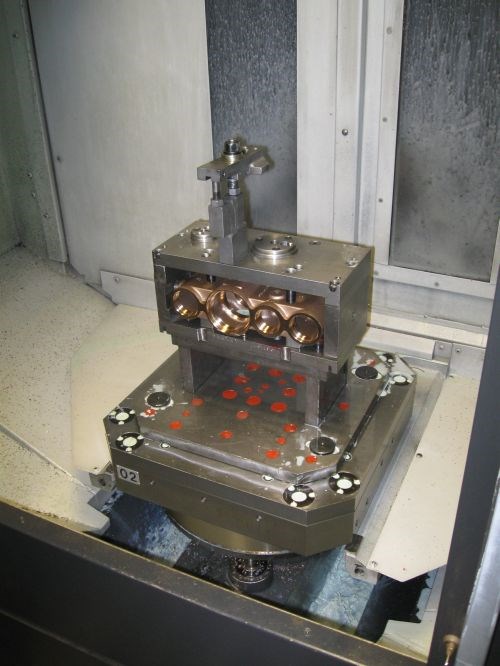

PM&E streamlined its shop floor (see the article) by adding quick-change workholding. Setup on the HMC became faster—but that very improvement made the time spent changing out tools more noticeable. According to the shop’s Nate Fleming, the HMC was using a 40-tool magazine to run six different part numbers that shared 35 tools in common. The shop was losing time on repeatedly swapping the tools that went in those remaining five positions.

The shop has a newer HMC now. It holds 59 tools—enough to keep all six part numbers set up at once. As a result, job change-over has gone from faster to much faster, simply because there is now no tool-related delay for switching from one of these six part numbers to another.

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)