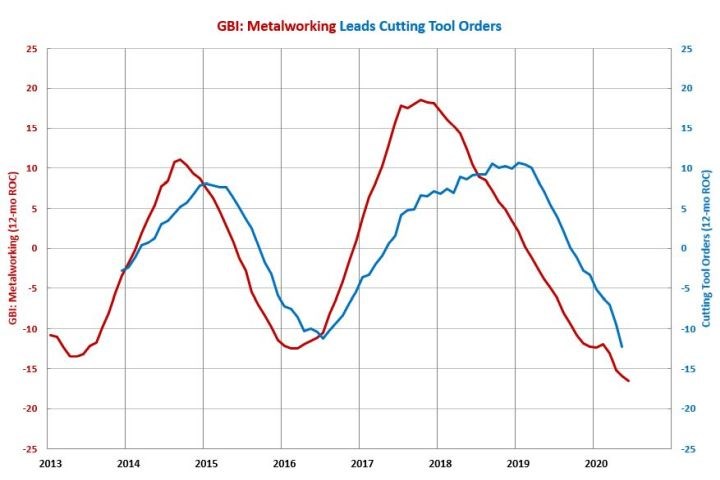

Cutting Tool Orders May Have Reached Low Point

The pandemic accelerated the contraction in metalworking and extended the accelerating contraction in cutting tool orders. But, the GBI: Metalworking indicates the lows in cutting tool orders may be in the past.

In May 2020, real cutting tool orders were $136.6 million, which was the sixth time in seven months that orders were below $190 million. Also, this was the lowest level of cutting tool orders since the data was made public in January 2012. Compared with one year ago, cutting tool orders contracted -36.5%, which was the 15th consecutive month of month-over-month contraction. Also, this was the fastest rate of month-over-month contraction since the data was made public and the second month in a row that contracted faster than 30%.

The annual rate of change contracted at an accelerating rate for the eighth month. The annual rate of contraction was 12.3%, which was the fastest rate of annual contraction since the data was made public. At the beginning of 2020, the Gardner Business Index: Metalworking indicated that the annual rate of contraction in cutting tool orders would bottom out in the summer of 2020. However, the pandemic accelerated the contraction in metalworking and extended the accelerating contraction in cutting tool orders.

A bottom in the rate of change in the index should be reached soon.

The GBI: Metalworking is a good leading indicator of cutting tool orders and leads cutting tool orders by seven to 10 months. The annual rate of change in the Index has contracted for 16 straight months, clearly indicating that the annual rate of contraction in cutting tool orders will continue to accelerate. While it is still contracting (an index level below 50), the GBI: Metalworking increased in May and June. Therefore, a bottom in the rate of change in the index should be reached soon. It appears that rate of change in cutting tool orders will bottom out in the late third quarter or fourth quarter of 2020.

Related Content

-

Toolpath Improves Chip Management for Swiss-Type Lathes

This simple change to a Swiss-type turning machine’s toolpath can dramatically improve its ability to manage chips.

-

How to Tackle Tough Angled Pocket Milling With Two Tools

Milling a deep pocket with a tight corner radius comes with unique challenges, but using both a flat bottom drill and a necked-down finishing tool can help.

-

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

.JPG;width=70;height=70;mode=crop)