Downsize Your Turning Inserts

A white paper written by John Mitchell from Tungaloy Canada.

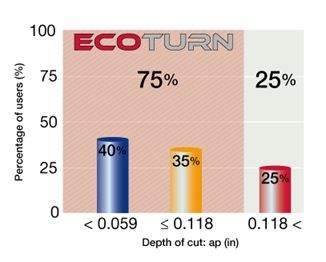

Many machine shops today are machining with inserts much larger than are required. There are two trends in the machining industry today that influence the decision to consider downsizing your inserts size. The first is the raw materials (tungsten and cobalt) used to produce carbide inserts are dramatically increasing in price. The second is manufacturing technology is advancing and parts to be machined are considered “near net”. That means the unmachined part is near its net size or there is little material to be removed. Over 75% of the turning market takes depth of cuts of 0.117" (3mm) or less. Yet many machine shops insist on using large size inserts. The most common turning insert sold in North America today is a CNMG 432. This insert is capable of almost 0.250" (6.35mm) depth of cut. Yet as mentioned earlier over 75% of the machining industry takes cuts of less than half of that depth. This seems wasteful.

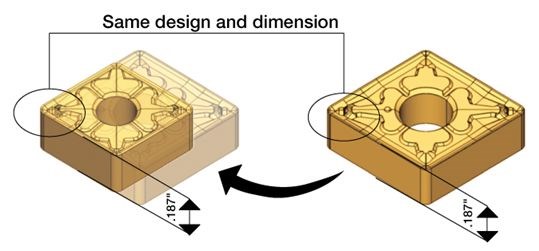

In order to maintain the same performance, integrity and fracture resistance of the tool the smaller insert should have a thickness close to equal that of the large inserts. The insert numbering system or “nomenclature” indicates the size of the insert. The first number specifies the size of the inscribed circle of that particular insert geometry. In the case of a CNMG 432, the 4 would translate to 4/8 or ½ inch inscribed circle. The second number points to the thickness of the insert. In this case a CNMG 432 the 3 shows a 3/16 inch thick insert and the last number indicates the radius of the insert. So if you are using a CNMG 432 insert, you can simply downsize to a CNMG 332 insert. Since the insert thickness is the same, the chip breaker and grade are the same the performance will be equal. However the price will be 20% less.

Some shops are reluctant to change, since they consider they have an investment in the tool holder. A typical holder for a CNMG 432 would be an ACLNR 16-4 which would typically list for $85.00. A CNMG 432 insert typically has a list price of around $11.25 where as a smaller CNMG 332 would typically have a list price 20% less or around $9.00. By downsizing your insert the break even on the tool holder would occur after only using 38 inserts. A typical tool holder is capable of lasting several hundred inserts. Of course this is only an extra cost on the first replacement as all tool holders eventually will wear out and need replacing. Of course there is no extra cost involved if the shop simply waits until the holder wears out and replaces it. However this is not recommended as the shop would be spending too much money on larger inserts.

This leads to another topic: Tool holders. Many shops tend to push the life of the tool holder without realizing the negative consequences. Tool holders are subjected to intense pressure, heat and abuse. Over time the pocket in a tool holder will “coin” or deform making the insert “fit” loose. This may cause the insert to move while in cut. This will lead to shorter tool life, slower performance and may result in catastrophic failure. It is sensible to change your holder often as it will help maintain high productivity, extend tool life and reduce the chance of catastrophic failure. Trying to save a few dollars by extending the life of the $85 tool holder generally ends up cost much more in reduced productivity, poor tool life and probable tool failure.

Read Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.png;maxWidth=300;quality=90)