Henkel Redefines Industrial Machining and Grinding with Sustainable Metalworking Innovation

Sponsored ContentWith innovative formulation and bio-resistant properties, Henkel’s new semi-synthetic lubricant emerges as a pioneering solution in the machining industry.

Share

Bonderite L-MR B-637, Henkel’s new boron-free, semi-synthetic metalworking fluid. Contact Henkel to learn more.

In the intricate world of industrial machining, where precision and productivity are paramount, the choice of metalworking fluids can spell the difference between success and stagnation.

Henkel Corporation, a global leader in industrial solutions, has recently introduced Bonderite L-MR B-637, a novel machining and grinding fluid poised to revolutionize the industry.

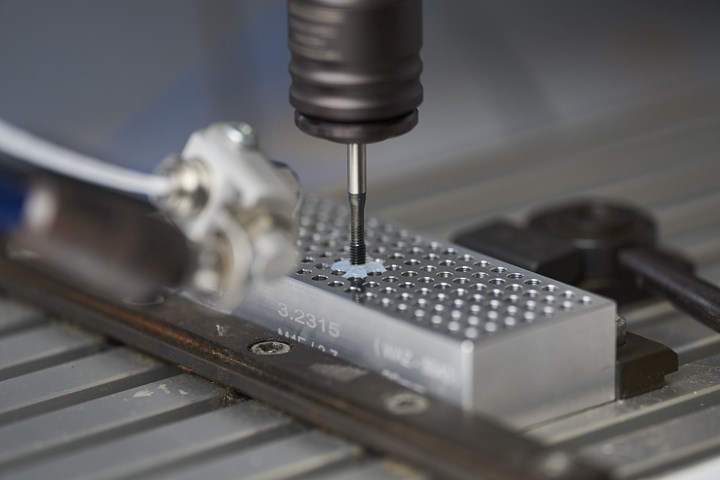

Bonderite L-MR B-637 (left) provides high emulsion stability compared to previous generations.

Positioned as a sustainable alternative, this bio-resistant, boron-free and semisynthetic formula represents a significant step forward in both performance and environmental responsibility. Industrial machining is a complex arena in which nearly every aspect – from environmental impact to operational efficiency – is scrutinized for optimization. Traditional metalworking fluids facilitate heat dissipation, reduce friction and prevent wear and tear. However, while crucial for smooth operations, they have long faced myriad challenges, from compatibility issues across various machinery and materials to performance limitations that hinder productivity. Manufacturers often struggle with additional concerns, such as excessive foaming, limited longevity and compatibility with various water sources, all of which can escalate maintenance costs. In response to such industry-wide concerns, Henkel Corporation has developed Bonderite L-MR B-637, which aims to redefine market standards by offering a comprehensive fix that prioritizes sustainability without compromising on function.

Key Attributes and Advantages of Bonderite L-MR B-637

At its core, Bonderite L-MR B-637 boasts a suite of features tailored to meet the demands of modern machining processes. Its bio-resistant formulation not only mitigates microbial growth but also aligns with evolving environmental regulations by eliminating boron. Designed for process requirements that make foam difficult to control, the metalworking fluid is excellent for heavy-duty ferrous or nonferrous machining. This versatility ensures seamless integration across machining and grinding operations, irrespective of water conditions or equipment specifications. In fact, the avoidance of boron aligns with industry trends and impending regulatory changes, as boron is anticipated to be phased out over the coming decades. The product’s Safety Data Sheet also reflects Henkel’s steadfast commitment to safety and sustainability. Unlike its counterparts, which often require multiple pictograms, Bonderite L-MR B-637’s SDS stands out for its simplicity, featuring just one.

Bonderite L-MR B-637 (right) undergoes rigorous stability testing, showcasing the product’s robust formulation.

The semi-synthetic fluid’s exceptional durability ensures long-term usage without degradation, providing consistent performance over time. With a unique blend of lubricity additives and cooling properties, Bonderite L-MR B-637 achieves high emulsion stability enhancing robustness and enabling versatile applications across machining and grinding tasks. It is also compatible with a wide range of water sources; from rugged terrains in the U.S. to mineral-dense canyons in Mexico, Bonderite L-MR B-637 adapts to every water source, making it the go-to for machinists everywhere. Its suitability for diverse machining environments caters to a broad customer base. Additionally, the metalworking fluid has antifoaming properties, contributing to a smoother machine process by reducing downtime, as well as biostable technology, eliminating the need for tank-side additives and next-day odors. These benefits address critical concerns of manufacturers, making this product a sought-after solution.

Bonderite L-MR B-637 produces virtually no foam, ensuring optimized manufacturing processes. Contact Henkel.

A Commitment to Sustainable Metalworking

Bonderite L-MR B-637 embodies Henkel’s dedication to environmental well-being and workplace safety in metalworking operations. Traditionally, boron has been a common ingredient in metalworking products, serving to inhibit bacteria and act as a fungicide. However, these biocidal properties pose environmental and health risks to both workers and ecosystems. In contrast, this innovative, boron-free formulation offers exceptional stability free of such associated risks. It also facilitates waste and energy reduction by enabling the recycling of cleaners in the metalworking process. As climate change looms and industries worldwide pivot towards sustainability, the importance of transitioning towards ecofriendly lubricants is essential not only for mitigating environmental impact, but also bolstering operational efficiency and regulatory compliance. Amidst this paradigm shift, products like Bonderite L-MR B-637 contribute to a cleaner, greener future for generations to come.

As a boron-free solution, Bonderite L-MR B-637 prioritizes safety and sustainability.

Pioneering Innovation

Henkel’s metalworking solutions reflect a deep understanding of the evolving needs of customers and the rapidly changing landscape of industrial manufacturing. Having successfully introduced many technologies to the market, the company approaches the development of Bonderite L-MR B-637 with a wealth of experience and expertise.

“We went outside the box and designed this with both our North American teams and our European counterparts,” said Jonathan Sheibels, Business Development Manager, Henkel. “We took best practices and formulated something that caters to customers everywhere.” With a keen focus on accessibility and widespread availability, Henkel aims to make Bonderite L-MR B-637 a ubiquitous solution for manufacturers worldwide, contributing to the advancement and sustainability of the machining industry for years to come.

Product Reflections

Bonderite L-MR B-637 emerges as a formidable force in the realm of metalworking fluids, fortified to revolutionize manufacturing processes across the globe. Its flexibility extends to multimetal applications, including steel cast, showcasing its robustness and longevity. With heightened emulsion stability and a boron-free formulation, Bonderite L-MR B-637 ensures optimal performance while prioritizing environmental sustainability. Its compatibility with any water source underscores its adaptability and ecofriendliness, acting as a beacon in the path to a more sustainable future in the machining industry. As manufacturers worldwide increasingly emphasize efficiency and environmental responsibility, Bonderite L-MR B-637 stands ready to meet and exceed expectations, ushering in a new era of innovation and sustainability in metalworking operations.

Bonderite L-MR B-637 is used during a drilling process, minimizing heat wear while cooling machinery.