The HYBRID Additive Manufacturing and Multi-Tasking Machining Revolution is Here

Sponsored ContentIt’s not just about additive vs. subtractive manufacturing anymore. A new class of machine tool combines multitasking machining with laser metal deposition as well as welding processes and gear cutting too.

Share

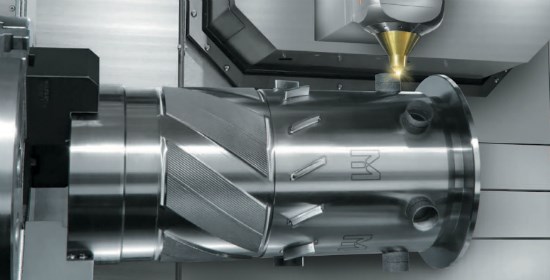

In the early 1980s, machine tool builders added milling spindles to turning machines, and Multi-Tasking was born. Within a decade, the concept quickly progressed to machines that not only combined turning, milling, drilling, tapping and boring capabilities, but that also incorporated second turning spindles, multiple tool turrets, Y-axis capability, tilt/rotary milling spindles and tilt/rotary worktables. With all that capability, manufacturers could transform raw material into finished parts in a single setup on one machine, which has come to be known as DONE IN ONE® Multi-Tasking.

Of the machine tool companies specializing in Multi-Tasking, none have progressed the concept further than Mazak. Today, Mazak’s lineup of Multi-Tasking machines can handle most, if not all, of a part’s machining and processing operations. The conventional form of Multi-Tasking suffers from one central limitation, though; all its operations are subtractive. However, a new class of machine from Mazak is driving the concept of Multi-Tasking to a whole new level by bringing still more processes into mix, all on a single platform.

The Next Generation of Multi-Tasking

Welcome to Mazak HYBRID Multi-Tasking, merging subtractive processes with additive and joining capabilities in previously unimaginable combinations. The HYBRID lineup broadens the subtractive capabilities of these machines, offering new ways to perform gear skiving and hobbing. The HYBRID lineup also adds powerful additive manufacturing (AM) and joining solutions like hot wire deposition (HWD), laser and multi-laser metal deposition as well as friction stir welding (FSW). More on these processes below.

HYBRID Multi-Tasking benefits parallel those that manufacturers first discovered in the technology’s early days—significantly reduced lead times, especially when factoring in research and development; streamlined process development; increased part accuracy; and the elimination of multiple changeovers and setups. Because Multi-Tasking machines integrate easily into automation solutions, like Mazak’s PALLETECH multiple pallet management system, manufacturers also can realize sharp reductions in operating costs and capital equipment expenditures.

Here A5356 aluminum beads are laid down with arc welding on the A5052 base material and then machined to complete a tire mold.

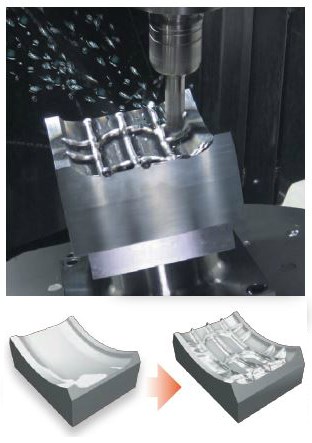

Additive manufacturing and joining, however, represent the point at which the HYBRID revolution begins to take Multi-Tasking to the next level. In the past, a part produced with an additive process would need finishing with traditional subtractive CNC machining, adding cost on top of cost. But HYBRID requires no separate second machine and no additional setups to bring DONE IN ONE® Multi-Tasking to an even wider range of applications.

For components that range from screw shafts to drill bits and artificial bones to pump impellers, subtractive processes require starting with raw material that accommodates the largest feature on the part. Given the cost of modern materials and alloys as well as the machining time involved, this can make for a very expensive part with a long turnaround time.

Inconel 718 is added to create new part features on this 304 stainless steel cylinder.

Instead, HYBRID Multi-Tasking machines can begin with an impeller shaft or the base of an artificial bone, for example, and use the additive head to build part features directly to save time, material and cost. The subtractive Multi-Tasking capabilities then quickly finish machining the rough surfaces created by the additive process. Switching from the additive head to a subtractive finishing tool requires only a few lines of G-code.

Although these new HYBRID technologies will transform manufacturing just as Multi-Tasking itself did, HYBRID's future also includes extending these systems to a greater number of machine platforms, with products such as a gantry-type single-laser additive head system. Such a system will allow for easy modification of the laser head and better protection for its sensitive optic system—while avoiding the need for large structural modifications.

For now, however, HYBRID Multi-Tasking represents a new frontier in manufacturing. Application engineers, process optimization experts and CAD/CAM software developers will discover ways to mix and match joining, additive and subtractive operations that improve productivity and efficiency.

Watch Mazak’s VC-500 AM HYBRID additive manufacturing machine in action.

Revolutionary Technologies

This new level of technology brings a host of new technologies to a machining platform that lets manufacturers produce more complicated parts at lower cost. Here’s an overview of what they can do:

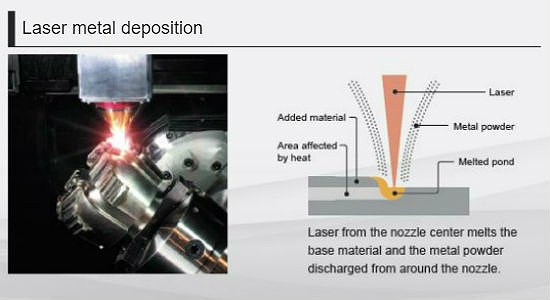

Laser metal deposition, also known as selective laser sintering (SLS), is perhaps the simplest form of additive manufacturing, using the heat of a laser to melt metal powder selectively. By far the fastest way to build parts with metal powder, single-laser metal deposition uses one high-power laser to melt powder as it’s shot from a nozzle. Mazak’s HYBRID machines, such as the VC-500 AM, place the nozzle on an additive head capable of moving in five axes, a significant improvement over the linear motion of most additive solutions. Thanks to this innovation, the VC-500 AM is ideal for joining two materials together or building part features with super alloys such as Inconel 718.

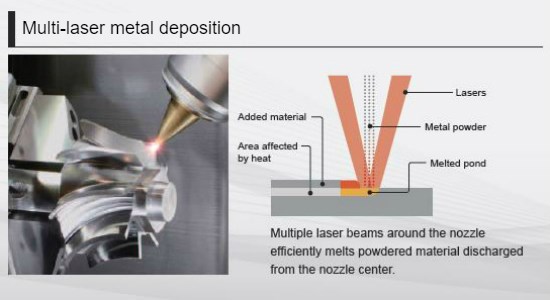

Multi-laser metal deposition takes this technology even further. On machines such as the INTEGREX i-200S AM, a gantry additive manufacturing head uses multiple lasers to perform micromachining and coating. With advanced CNC controls, the machine can direct powder from any angle and combat any deviation caused by gravity while the AM head is tilted. These AM heads can use the heat of multiple lasers, quickly coating stainless steel with materials such as Stellite No. 6 for applications that involve impellers or other heat- and wear-sensitive parts.

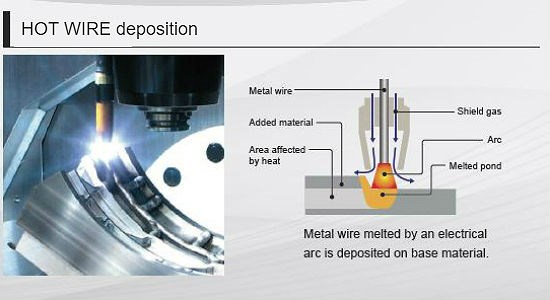

HOT WIRE deposition takes advantage of wire arc additive manufacturing, a high-speed additive solution that offers programmable welding automation. As with conventional welding, an arc torch melts wire directly onto the base material. This allows for exceptionally precise sealing coatings as well as the production of near-net shape part features. On Mazak’s new HOT WIRE machines, the wire arc AM head can feature the same 5-axis capability as a milling spindle, allowing manufacturers to build new part features or welds on all of a workpiece’s surfaces.

Friction Stir Welding (FSW) is an older joining strategy that gains new life in Mazak’s HYBRID ecosystem. FSW applies highly precise levels of frictional heat and forging pressure to create full-penetration, defect-free welded joints. Compared to traditional welding, FSW makes it simple to minimize heat-affected zones and avoid any difficulties when joining flat, cylindrical or irregularly thick components. As a result, machines equipped with FSW heads produce parts such as semiconductor chamber components with far greater ease than ever before.

AUTO GEAR generation brings new subtractive processes to the HYBRID family, making it possible to eliminate farming out gear machining work entirely. SMOOTH gear milling, gear skiving and gear hobbing use software to make gear production simple, reducing the need for complex programs or specialized machines.

Although conventional gear machining is a proven process that excels in medium to high-volume production environments, it often results in longer lead times, special tool requirements, redundant work holding and a higher capital investment. The HYBRID process brings all of those functions to a traditional 5-axis machining center, creating a single setup for even the most geometrically complex gear types. The cost savings from accomplishing processes such as gear chamfering and edge prep in a single setup add up quickly for any shop with low- to medium-volume gear production needs.

For more information visit Mazak. See Mazak at IMTS in their HYBRID Multi-Tasking booth (43200) in the West Building and their general metalworking booth (338300) in the South Building.