Bar Pullers: A Lower-Capacity Alternative to Bar Feeders

For shops with limited space or funds, a bar puller may provide an effective and accessible way to automate a lathe.

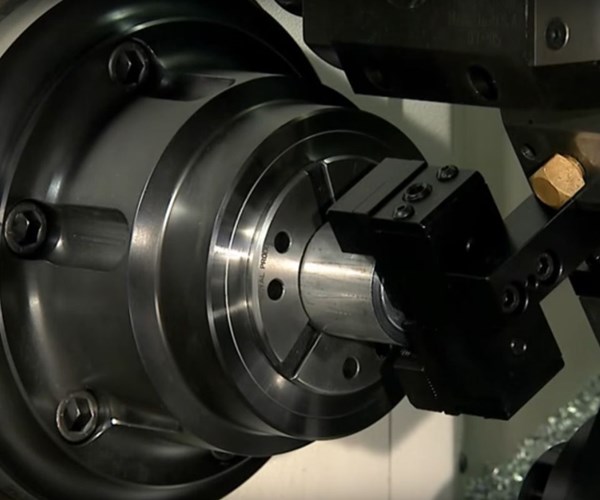

Operating a lathe means turning barstock into parts. Bar feeders push (or feed) a bar of stock into the lathe until the bar has been fully utilized. Then the bar feeder continues to load bar after bar until the job is complete or the hopper is out of stock. However if only a single bar of stock is necessary, or a shop does not have the space or money for a bar feeder, a bar puller can be used to easily automate any CNC lathe or turning center.

Like a bar feeder, a bar puller can improve productivity by enabling CNC lathes to run unattended and permit operators to handle other tasks. Under the right conditions, bar pullers have a number of advantages. They are inexpensive (just hundreds of dollars) and can be easily fit to most CNC lathes.

They are also easy to set up and use, as no electrical interface with the machine tool control is required. The bar puller is engaged via a typical tool change. The two main variants of bar pullers are spring-loaded jaw-type pullers and air/coolant-actuated finger-type pullers. Spring-loaded pullers can have either manually adjustable jaws that slide over the stock, or rollers (which negate the need for manual adjustment). There are spring loaded pullers available as combination puller/cutters that can cut off a finished part before pulling more stock. Air/coolant-actuated pullers usually have three fingers with which to grip the barstock by the end. These fingers have hardened inserts to prevent wear.

Although bar pullers do not take up the floor space bar feeders do, a simple bar puller does not offer production capacity to a machine at the level a bar feeder does. The added stock capacity of a bar feeder is worth the cost and real estate in the case of a machine tasked with producing a massive lot of parts. The size and frequency of jobs will help determine which option is best.

This article originally appeared on imts.com. Bar puller image courtesy of Royal Products.

About the author: Stephen LaMarca is AMT’s manufacturing technology analyst. He has a background in physics and a passion for all things mechanical, namely automobiles, clocks and wristwatches.

Related Content

-

Niche Work If You Can Get It: A CNC Machine Shop Crafts Its Own Destiny

The latest innovations in metalworking aren’t always related to CNC automation or robotics. For Rosenberger North America, a 2022 Top Shops Honoree, it is the company’s niche processes that create the biggest successes.

-

Using the Toolchanger to Automate Production

Taking advantage of a feature that’s already on the machine tool, Lang’s Haubex system uses the toolchanger to move and store parts, making it an easy-to-use and cost-effective automation solution.

-

Lean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

.png;maxWidth=300;quality=90)