Because the Definition of “Production” is Changing

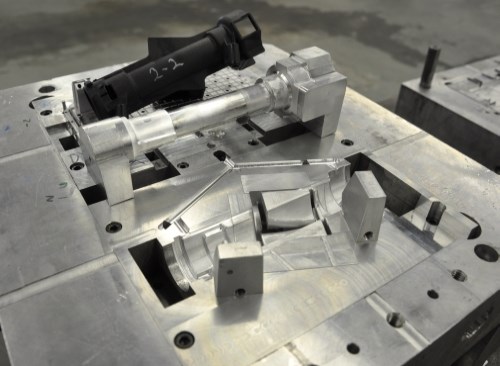

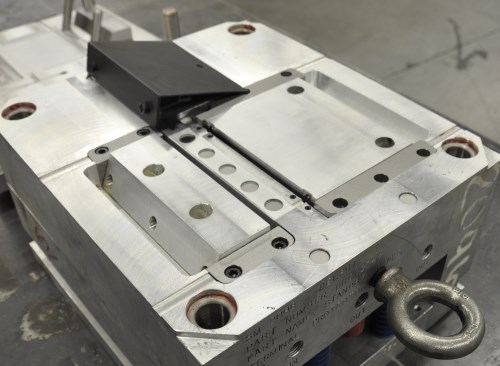

Phoenix Proto Technologies creates aluminum molds for both prototyping (like the left one with hand loads) and production (like the right one with mechanical actions). When we launched our Prototyping & Rapid Manufacturing Zone, we wanted rapid mold making to be a part of it.

|

|

|

Phoenix Proto Technologies creates aluminum molds for both prototyping (like the left one with hand loads) and production (like the right one with mechanical actions).

When we launched our Prototyping & Rapid Manufacturing Zone, we wanted rapid mold making to be a part of it. That’s because while aluminum molds have been commonly used to create prototypes or to serve as stopgap bridge tooling, they’re starting to receive greater attention for production work.

What’s driving this trend is the definition of “production.” It’s changing. Because OEMs want to introduce new products more frequently, requisite part volumes are not as high as they once were for some applications. A mold that can deliver 1 million shots may be sufficient to satisfy an injection molding production run. When properly designed and machined, aluminum molds can achieve this level of production. Plus, manufacturers are beginning to realize that compared to steel, aluminum molds can be created quicker, cost less and enable faster injection molding cycle times due to better thermal characteristics.

My story explains how Phoenix Proto Technologies creates aluminum molds in one day to three weeks. It includes a bit of video in which the shop’s director of sales explains primary differences between the aluminum molds the shop produces for prototypes versus the aluminum molds it produces for production.

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)