Event Highlights Automotive Production Solutions

Makino recently highlighted various examples of its latest automotive production technology and detailed strategies for responding to the pressure faced by manufacturers in that industry.

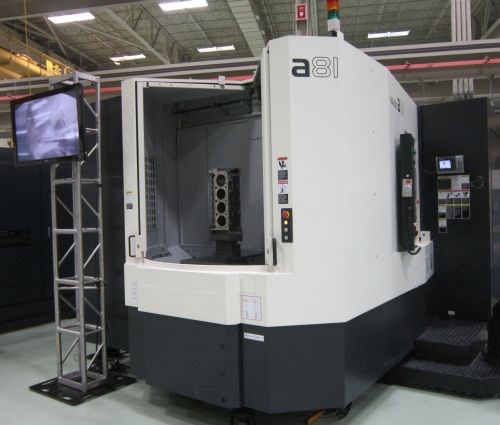

One demo involved machining of a cast iron engine block, shown here in the pallet station of the Makino A81 HMC. Demonstrated processes included closed-loop boring and finish-honing operations.

As the North American automotive industry moves from recession to recovery, manufacturers are contending with not only increased volumes, but also increasingly compressed lead times, a range of new product designs and more stringent quality-control requirements. “Automotive and Part Production Day,” a May 8 event at Makino’s headquarters facility in Mason, Ohio, revealed steps the machine tool builder has taken to keep itself—and by extension, its customers—ahead of these trends.

North American light-duty vehicle production moved from 8.6 to 15.4 million between 2011 and 2012 and is expected to continue to increase, a result of reshoring, OEMs moving to global platforms, and increasing quality standards, among other forces. Equipment demand has followed suit, and Makino has increased inventories to ensure quick deliveries of production resources suited for the smaller, lighter components used in today’s increasingly efficient engine designs. Chief among such equipment is horizontal machining centers with 400- to 500-mm pallets, such as the company’s a51nx and a61nx models, of which it sold more than 300 last year.

Likewise, the company is boosting stocks of automation accessories that it deems critical to extract the most efficiency from these machines. Specific examples include robot interfaces, continuous pressure hydraulic fixture control, automatic stacker doors, tool-break detection functions, machine monitoring software and more.

The company has also ramped up its service and support offerings by increasing regional staffing of field service engineers and applications specialists. This is especially critical in an era when automotive suppliers depend on automated production systems that are tailor-made to fit their specific needs. It also marks a departure from the model in place about a decade ago, when most support functions were handled directly from the Mason office.

Click here for more specific information on the various Makino technology and support offerings that were the focus of presentations and product demos throughout the day.