From Shop to Shop Management Software Provider

A co-founder of a machine shop that developed its own web-based shop management software explains why the decision was made to sell the shop and go into the software business.

ProCNC is a shop I’ve written about a couple of times. In “Creating A Machine Shop Franchise Template,” I describe how the shop applied basic franchising concepts to maximize efficiency in all aspects of its business. In “Committed to Kaizen,” I explain why the shop devoted 5 percent of company time to continuous improvement activities.

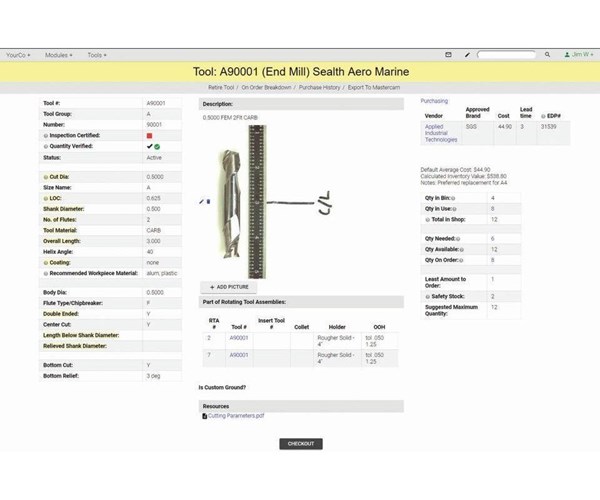

One interesting aspect of this shop is that it developed a web-based shop management system for its own internal use. But after agreeing to sell its system to a nearby shop called Sealth Aero Marine and seeing how Sealth benefitted from it, the decision was made to get out of the machine shop business and into the software business by forming Adion Systems.

Adion calls its software ProShop. Since implementing this web-based shop management system, Sealth’s annual sales have increased 125 percent while its workforce has increased by only 15 percent. Read this story to learn more about how it benefits from this web-based shop management system, which includes various individual software modules needed to track and manage jobs, work estimates, customers, scheduling, purchasing, costing and quality.

Related Content

-

Improving Workflows in Small Shops with Custom ERP

Small shops might not be ready for all of the functionality of an off-the-shelf ERP system, but modular, custom ERP programs can help improve workflow while providing the flexibility to change as shops grow.

-

Finally, A Comprehensive Software Solution Designed for Small Job Shops

Zel X from Siemens is an integrated software application that consolidates collaboration, design, manufacturing, and operations into a comprehensive, easy-to-use solution. From RFQ to delivery, it’s a more efficient way to handle quotes, manage jobs, make parts, and collaborate with teams of all sizes.

-

Shop Moves to Aerospace Machining With Help From ERP

Coastal Machine is an oil and gas shop that pivoted to aerospace manufacturing with the help of an ERP system that made the certification process simple.

.jpg;width=70;height=70;mode=crop)