Integrating Robot Programming into the CNC: One Example

This combination of robotics, CNC, workholding and machine tool technologies resulted in a streamlined way to integrate and program an automated machine-tending process.

For this demonstration, the robot performed both workpiece pallet changeout and simulated polishing operations of machined parts.

I’ve been aware of the Run MyRobot capability available with Siemens Sinumerik controls for a little while, but I believe the cell below that was in Handtmann’s EMO Milan booth represents the first time I’ve seen a demonstration of the concept using an actual machine tool.

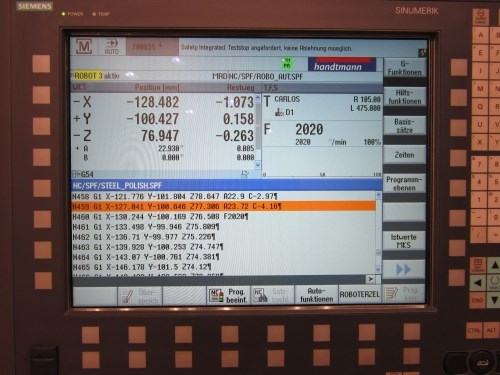

The idea is to provide intuitive robot programming capability at a machine’s CNC via the Sinumerik Operate GUI. In the case of this cell, the execution of the movements of the six-axis Kuka KR 600 Fortec robot (with 600-kg load capacity), provision of robot safety functions and other robot-specific functions are performed by the Kuka KR C4 robot control. However, that control is connected to the Handtmann five-axis HBZ Trunnion 80 machine’s Sinumerik 840D sl CNC. Therefore, the machine tool operations and robot program can be tracked and controlled on one screen via parallel channels.

The machine tool operations and robot program can be tracked and controlled on one CNC screen via parallel channels (the robot channel is shown here).

For this demonstration, the robot performed both workpiece pallet changeout (using Schunk clamping systems) and simulated polishing operations of machined parts. Of course, the robot can be used to perform a range of secondary operations, including drilling, brushing and deburring, depending on a manufacturer’s needs.

Check out this video that shows the cell at the show.

Related Content

-

Partial Automation Inspires Full Cobot Overhaul

Targeting two-to-four hours of nightly automation enables high-mix manufacturer Wagner Machine to radically boost its productivity past a single shift.

-

Modern Bar Feeds Bring New Life to Automatic Swiss Lathes

Cam-actuated Swiss lathes are still the fastest way to process many parts. By adding modern bar feeders, this shop has dramatically improved their utilization with the ability to work unattended, even in a lights-out environment.

-

Zero-Adjustment Bar Pullers Simplify Turning Automation

Spring-loaded grippers and adjustable programming are enabling bar pullers to fulfill their promise to save time and money in CNC turning automation.

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)