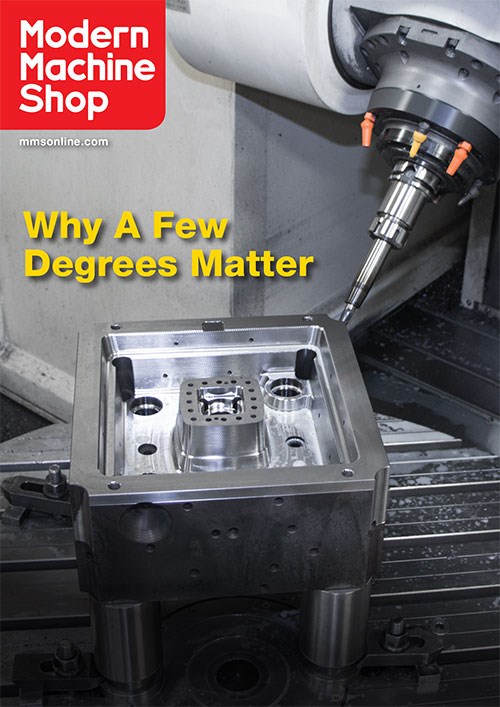

Why a Few Degrees Matter

3 + 2 machining might not be as captivating as five-axis contouring operations, but it can be just as valuable.

Five-axis machines enable two types of multi-axis machining operations: full contouring and positioning (a.k.a. 3 + 2 machining). Thought of as siblings, contouring would be the alluring one and 3 + 2 would be more on the homely side. This is because contouring operations feature complex simultaneous motion of all five axes during a cut while 3 + 2 only uses the rotary axes to position and then lock the tool and/or workpiece at different angles outside of the cut.

That said, many shops find great value in 3 + 2. One is Canada’s Moulexpert. It now leverages 3 + 2 to manufacture more reliable and effective molds for thin-walled containers. Among other benefits, this capability has enabled it to reduce setups of mold inserts from as many as 25 to two, as detailed in this story.

Related Content

-

10 Things to Know About Creep-Feed Grinding

Because of the high material removal rate creep-feed grinding can deliver in challenging materials, grinding might not be just the last step in the process—it might be the process.

-

A New Milling 101: Milling Forces and Formulas

The forces involved in the milling process can be quantified, thus allowing mathematical tools to predict and control these forces. Formulas for calculating these forces accurately make it possible to optimize the quality of milling operations.

-

How to Reduce Cycle Times by 70% and More on Your Existing CNCs and Dramatically Improve Tool Life Too

By employing advanced high efficiency milling techniques for the entire machining routine, SolidCAM’s iMachining technology can drastically reduce cycle times while vastly improving tool life compared to traditional milling.

.jpg;maxWidth=970;quality=90)

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)