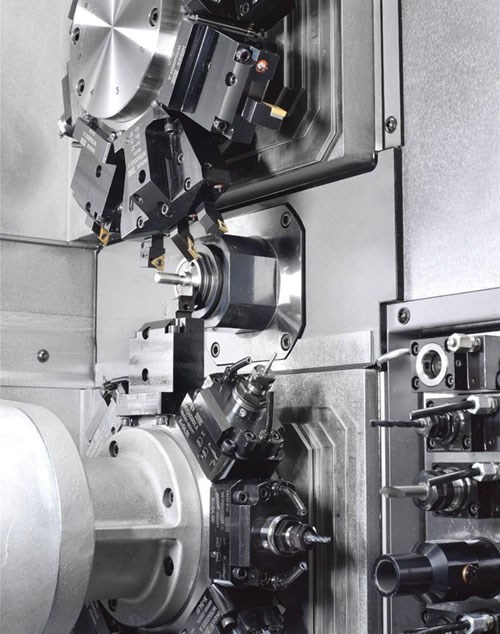

Why Shops Are Considering Swiss-Types

These days, more traditional job shops are installing—or at least eyeing—Swiss-types. Here are some reasons why.

so they can perform conventional turning.

Related Content

-

Inverting Turning and Five-Axis Milling at Famar

Automation is only the tip of the iceberg for Famar, which also provides multitasking options for its vertical lathes and horizontal five-axis machine tools.

-

Building an Automation Solution From the Ground Up

IMTS 2022 provides visitors the opportunity to meet with product experts to design automation solutions from scratch.

-

Modern Bar Feeds Bring New Life to Automatic Swiss Lathes

Cam-actuated Swiss lathes are still the fastest way to process many parts. By adding modern bar feeders, this shop has dramatically improved their utilization with the ability to work unattended, even in a lights-out environment.

.jpg;width=70;height=70;mode=crop)