The first step in automation is often the hardest: beginning.

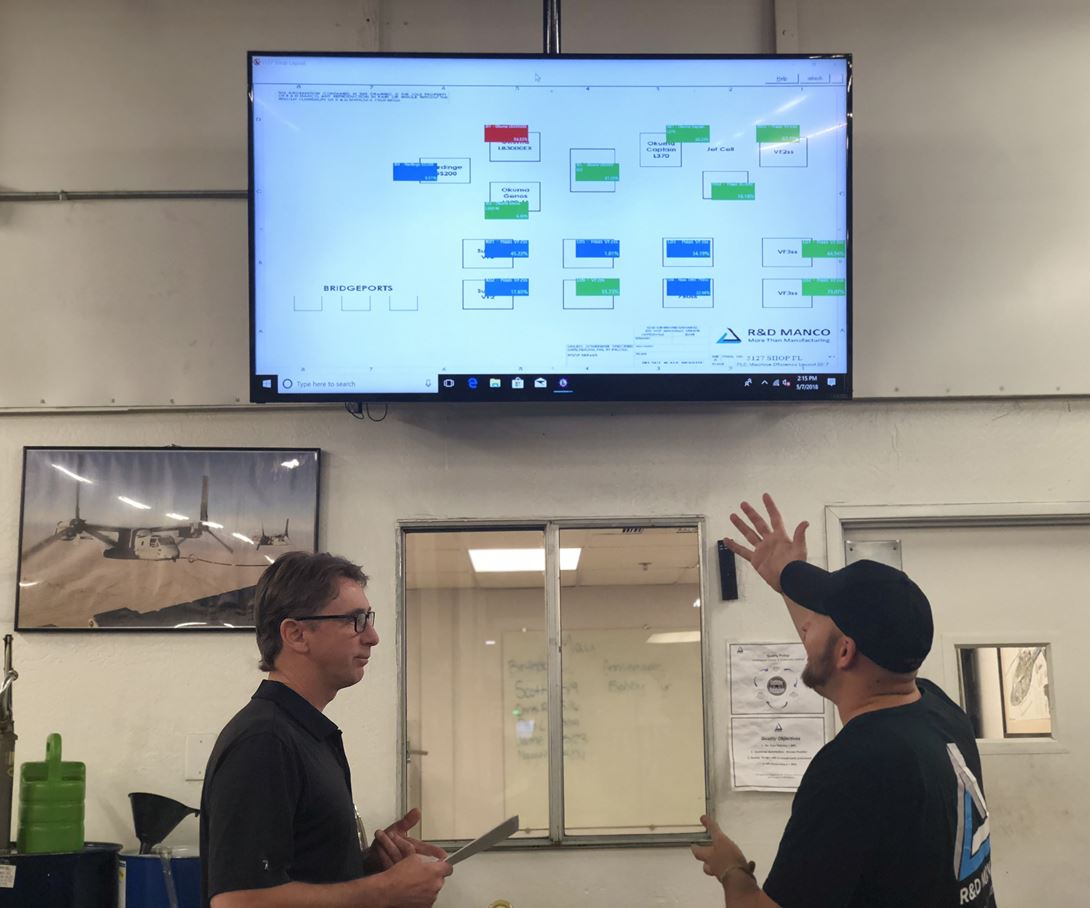

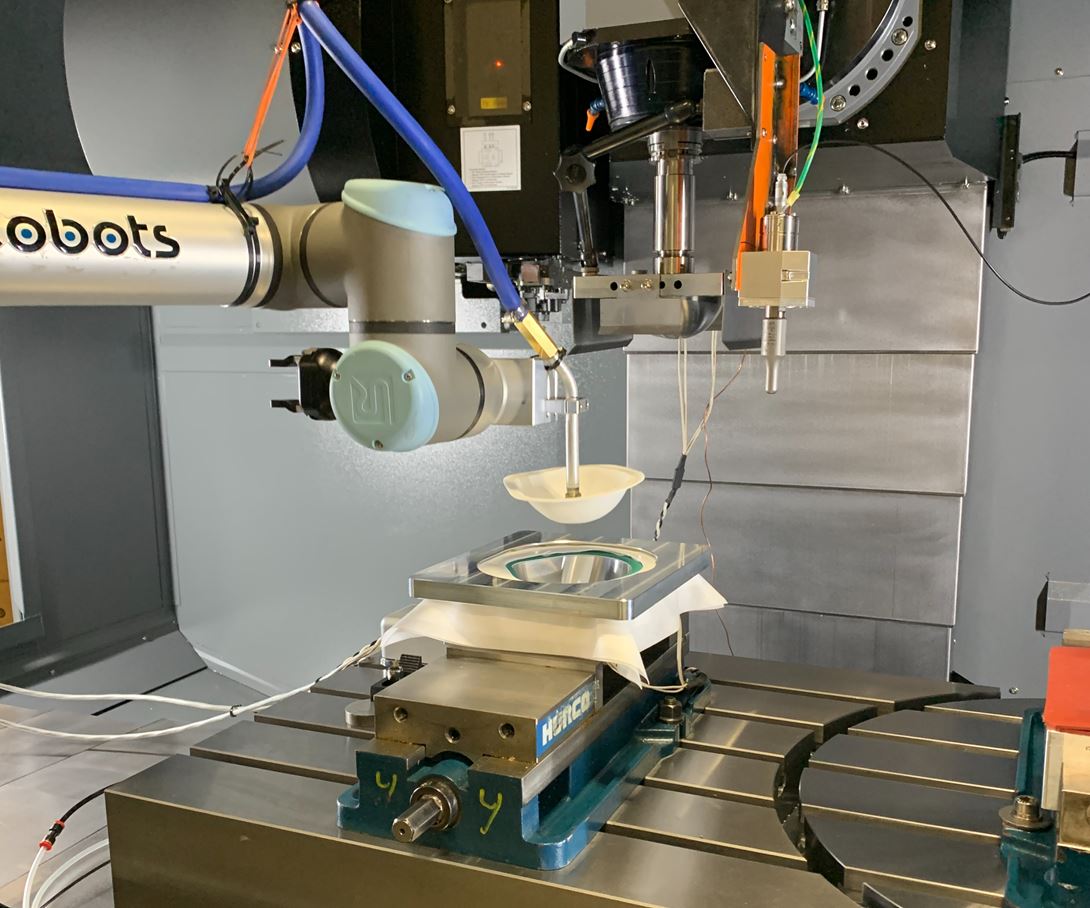

Many shops choose to start with simple forms of automation technology and build it step by step, process by process, to meet future needs. Cobots are a good example of this because their flexibility enables them to be added to an existing production process without safety cages or an in-depth integration processes. With beginning forms of automation in place, shops must decide what to do next. At this point, automation efforts become intertwined as they build out from each other. Modern Machine Shop Editor-in-Chief Peter Zelinski addresses this mingling of technology advances in the article to the left. He argues that automation, specifically lights-out machining, is becoming more common in machine shops because more shops are adapting a continuous-improvement mindset.