Browser-Based Software Simplifies Custom Tool Ordering

The Tool-Architect program from Allied Machine & Engineering speeds the design and estimate process for modular Wohlhaupter tools.

Available from Allied Machine & Engineering (AME; Dover, Ohio), Wholehaupter Tool-Architect software is designed to streamline the design, quoting, manufacturing and shipping of Whohlhaupter custom tooling.

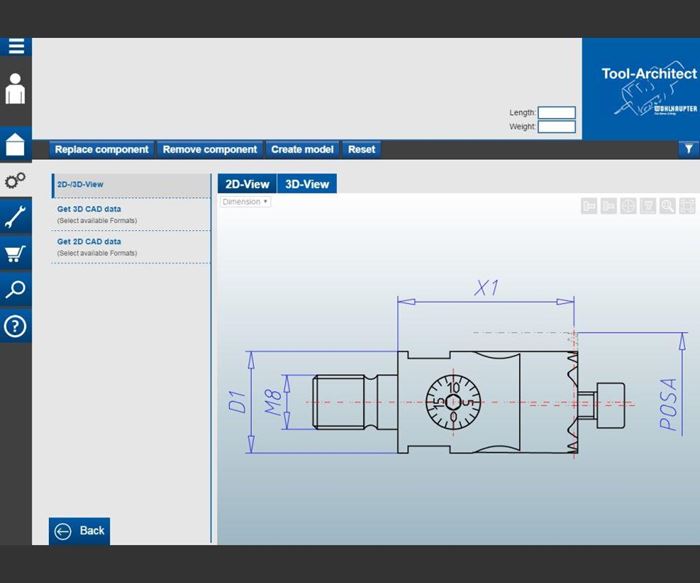

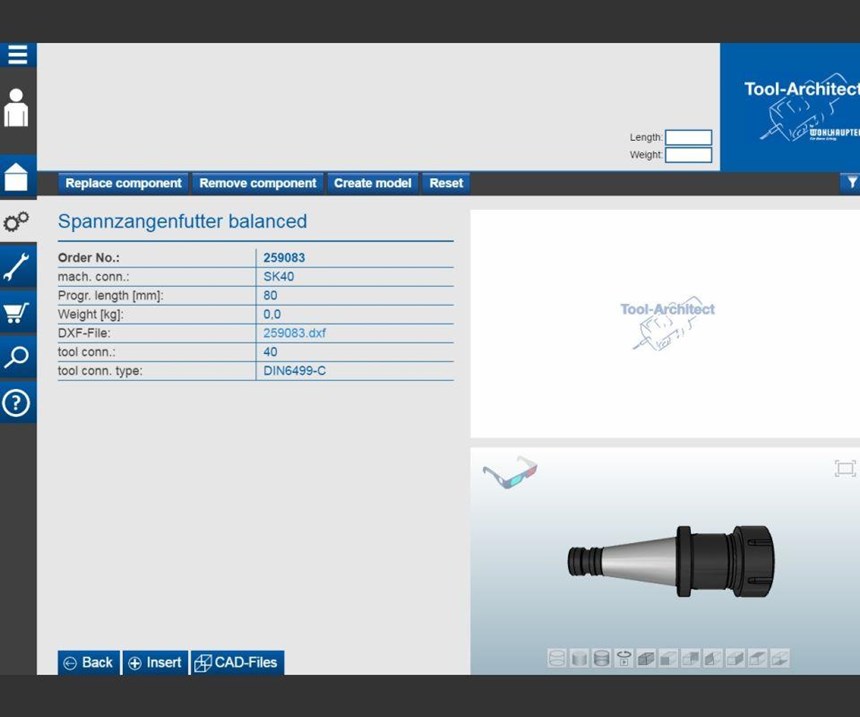

The online browser-based configurator simplifies product selection by enabling users to build custom, modular holemaking and finishing tools virtually. The system presents the entire Wohlhaupter inventory in a digital bank that includes every part the company manufactures in both inch and metric measurements. Various search filters help narrow the selection. After choosing a part, the user follows a series of prompts to select more parts and finish building their tool, tracking size and other information throughout the process to ensure a match with real-life specifications. After assembly, the program will render the tool in either a 2D or 3D drawing for the customer to view on the computer screen. Projects can be saved for later adjustment or sent through a shopping cart option to Wohlhaupter engineers for price estimate.

The intent of the system is to avoid the scenario of sending a design to a supplier, then waiting as long as a week to find out whether the tool can be created. Rather, the user can immediately check to see if their project needs adjustment in order to be manufactured. The program is free to use with an account at tool-architect.com.

Related Content

-

10 Tips for Titanium

Simple process considerations can increase your productivity in milling titanium alloys.

-

Threading On A Lathe

The right choices in tooling and technique can optimize the thread turning process.

-

All-Around Mill Improves Productivity and Cost for Valve Job

Adopting a mill with a double-negative rake and pockets compatible with multiple insert geometries enabled Progressive Metal Service to increase feed and lower scrap rates for a valve.

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)