Allied Machine's T-A Pro Drills Improves Holemaking

Allied Machine recently announced the T-A Pro spade drilling insert as a new high performance go-to for general purpose holemaking.

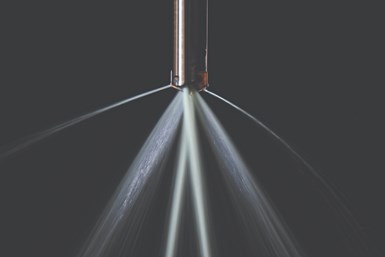

Allied Machine and Engineering’s high-penetration drilling system, the T-A Pro is designed to heighten performance in its “go-to” solution for general purpose holemaking.

The drill combines material-specific insert geometries, a redesigned drill body and a proprietary coolant-through system intended to allow penetration rates the company says are nearly 30% faster than other high-performance drills. Coolant outlets are designed to direct maximum flow to the cutting edge, providing quick heat extraction even at significantly higher speeds. Material-specific insert geometries produce quality chip formation, while the drill body incorporates straight flutes redesigned for maximum coolant flow and rigidity. According to the company, these design elements will extend tool life, create consistent quality holes and provide superior chip evacuation, combining to a cost per hole averaging 25% less than existing drills.

The T-A Pro drilling system is available in diameters ranging from 0.4370" to 1.8820" (11.10 to 47.80 mm) and is suitable for holes with stub, 3×D, 5×D, 7×D, 10×D, 12×D and 15×D depths. Drill variants include imperial and metric shanks with flat and cylindrical designs. The carbide insert geometries offered initially will cater to the following ISO material classes: steel (P), with AM300 coating; cast iron (K), with TiAlN coating; and non-ferrous (N), with TiCN coating.

Related Content

-

How to Tackle Tough Angled Pocket Milling With Two Tools

Milling a deep pocket with a tight corner radius comes with unique challenges, but using both a flat bottom drill and a necked-down finishing tool can help.

-

Emuge-Franken's New Drill Geometry Optimizes Chipbreaking

PunchDrill features patent-pending geometry with a chipbreaker that produces short chips to control machining forces.

-

New Modular Tool Options for Small Spindle Milling

Tooling options have been limited for small spindle milling applications. Now modular, indexable systems are available that provide broad flexibility to get the right cutter for the job with less inventory and at lower cost.

.png;maxWidth=300;quality=90)