Carbide Cutting Tools Imported From Portugal

IMTS22: Pilot Precision Products partners with Palbit, a Portugal-based manufacturer, to bring carbide cutting tools overseas, enabling easier access to these tools optimized for aerospace, automotive, defense, medical, die and mold, and railway sectors.

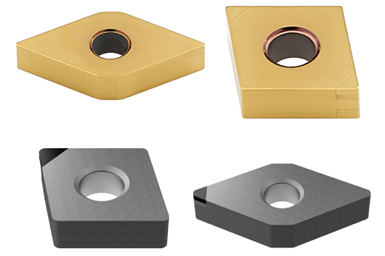

Pilot Precision Products, an American manufacturer and supplier of industrial broaches and round cutting tools is beginning to import cutting tools made by Palbit S.A., a 100 year old, Portugal-based vertically integrated manufacturer of carbide tooling. By making its own raw powder blends, unique coatings and proven geometries, Palbit creates a full line of indexable carbide milling, drilling and turning tools. According to the company, users of this line are supposed to get up to 60 percent more total value out of their tools.

Palbit’s high-precision carbide cutting tools and tooling solutions are used in a wide range of machining operations, including milling, turning, drilling, threading, grooving and parting.

Through this arrangement, Pilot is importing and distributing Palbit’s tooling through United States channel partners, making it easier to buy a tool good for applications in sectors like aerospace, automotive, defense, medical, die and mold, railway and more.

Pilot hopes its representation of this brand in the US elevates its position as a full-service, full-line concierge, making quality precision tooling available to its customers. Pilot also hopes for opportunities to strengthen its distributor network through this partnership by helping distributors get Palbit’s product line into customers’ shops. Palbit says it is equally honored to have Pilot hosting its product line in the United States.

Related Content

-

Threading On A Lathe

The right choices in tooling and technique can optimize the thread turning process.

-

Toolpath Improves Chip Management for Swiss-Type Lathes

This simple change to a Swiss-type turning machine’s toolpath can dramatically improve its ability to manage chips.

-

New Modular Tool Options for Small Spindle Milling

Tooling options have been limited for small spindle milling applications. Now modular, indexable systems are available that provide broad flexibility to get the right cutter for the job with less inventory and at lower cost.

.png;maxWidth=300;quality=90)