Guided TA Tool Overcomes Cross-Hole Drilling Hurdles in Moldmaking

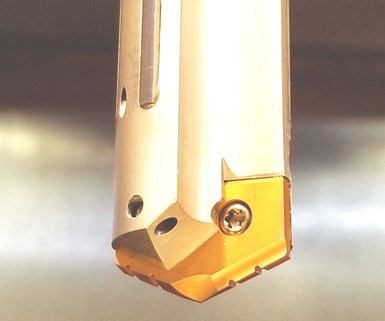

Allied Machine & Engineering’s Guided TA drill for moldmaking applications is used for producing water lines.

Allied Machine & Engineering’s Guided TA drill for moldmaking applications is designed to overcome two primary hurdles associated with cutting waterlines in large molds: tool failure in deep cross holes, and chip evacuation. Intersecting channels often connect off-center or at non-perpendicular angles. The interrupted cuts can cause premature tool failure if cutting forces are imbalanced. In addition, deep holes can present issues with proper chip formation and removal.

To ensure stability, the Guided TA drill features minimal clearance between the holder and blade. It also incorporates guided wear pads for straightness and stability and two adjustable Torx Plus screw pins for total indicator runout reduction via simple diameter adjustment. These features are said to enable the tool to drill to an 84" depth of cut while producing balanced cutting forces and small chips for optimal evacuation.

Related Content

-

Walter Launches New Solid Carbide Drill

The DC118 Supreme solid carbide drill provides high rigidity against deflection, superior centering accuracy and four margins with corner chamfers.

-

How Lowering Torque Improves Tapping Tool Life

Escaping the tap breakage trap requires a long look at torque and the many factors that influence it.

-

10 Ways Additive Manufacturing and Machining Go Together and Affect One Another

Forget “additive versus subtractive.” Machining and metal additive manufacturing are interconnected, and enhance the possibilities for one another. Here is a look at just some of the ways additive and machining interrelate right now.

.png;maxWidth=300;quality=90)