Mini Workpiece Positioning System Offers Fast, Flexible Setup

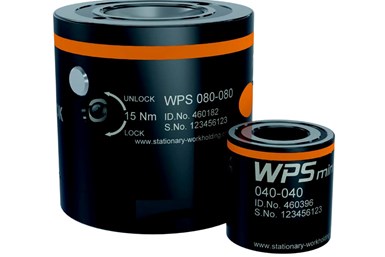

SMW Autoblok’s 40-mm Workpiece Positioning System (WPS) Mini is designed to reduce setup times and offer flexibility, especially for small workpieces that require quick part changeover.

SMW Autoblok Mini WPS

Photo Credit: SMW Autoblok

SMW Autoblok has introduced the 40-mm Workpiece Positioning System (WPS) Mini. The company says it is well-suited for small workpieces that require quick part changeover. The workholding system is designed with an emphasis on flexibility and speed, and it can reduce setup time by 90%, according to SMW Autoblok. It is designed to be interchangeable with all types of industry stationary workholding systems.

The WPS Mini features manual zero point clamping that attaches directly to the workpiece, provides maximum holding force of 25 kN and repeatability of less than 0.005 mm. Single, quick actuation is designed to provide rapid open and closing of the module with a 270° rotation.

The system is Proofline-sealed against dirt and swarf. It can be used with standard WPS and APS modules with special clamping pins and adapters that are case-hardened with corrosion-resistant coating.

The WPS Mini is part of SMW Autoblok’s full line of WPS clamping modules, which are offered in 60-, 80- and 160-mm heights. All modules can be mounted on a t-slotted table or grid plate manufactured with highly tempered quality steel with a specialized coating to protect against rust and contaminants.

Related Content

-

Custom Workholding Principles to Live By

Workholding solutions can take on infinite forms and all would be correct to some degree. Follow these tips to help optimize custom workholding solutions.

-

An Additive Manufacturing Machine Shop

Finish machining additively manufactured implants requires different pacing and workflow than cutting parts from stock — different enough for an experienced manufacturer to warrant a dedicated machine shop.

-

Lean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

.JPG;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)