Open Mind CAM Software Provides Ultrasonic Knife Cutting

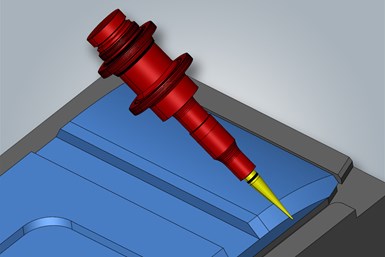

Ultrasonic knife cutting enables efficient cutting of honeycomb structures, composites and foams often found in aerospace, automotive and wind turbine applications.

Open Mind Technologies, a CAD/CAM software solutions developer, now offers a precise, productive ultrasonic knife cutting strategy via its HyperMill CAM software. Ultrasonic knife cutting enables efficient cutting of advanced materials, including honeycomb structures, composites and foams often found in aerospace, automotive and wind turbine applications. HyperMill CAD/CAM provides utility ranging from 2.5D machining to five-axis milling, as well as ultrasonic cutting with oscillating cutting blades.

According to the company, HyperMill provides NC code simulation to reliably bring challenging six-axis output to the machine. Using HyperMill’s Virtual Machining Optimizer to control the orientation of the spindle as the sixth axis, the cutting blade is aligned to the workpiece. The Optimizer keeps toolpaths within limits for demanding machining processes with limited rotation axes, such as a fork-head style milling machine (with the machine head having two rotary axes).

“Creating the required six-axis NC programs for knife cutting applications, including five machine axes plus a programmable spindle orientation, has historically proven to be a challenge,” says Alan Levine, managing director of Open Mind Technologies USA Inc. “However, HyperMill provides users with a productive, accurate, safe and smooth cutting solution which prevents hazardous rotations and retract movements.”

Related Content

-

Automated CAM Programming – Is Your Software Really Delivering?

A look at the latest automation tools in Autodesk Fusion 360 software and how forward-thinking machine shops and manufacturing departments are using them to slash delivery times and win more business.

-

How this Job Shop Grew Capacity Without Expanding Footprint

This shop relies on digital solutions to grow their manufacturing business. With this approach, W.A. Pfeiffer has achieved seamless end-to-end connectivity, shorter lead times and increased throughput.

-

Large-Format Machining With Small Cutting Tools and Dynamic Motion

Napoleon Machine, a defense contractor that provides parts for the M1 Abrams tank, recently took advantage of a CAM feature that allowed the company to streamline its cutting strategies and program offline. Here’s how the shop cut cycle times nearly in half with its large-format five-axis machining operations.