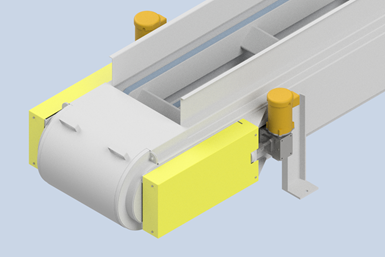

PRAB's Auto-Take Up Cuts Conveyor Belt Adjustment Downtime

PRAB’s new conveyor enhancement automatically tightens belts and eliminates the need for manual adjustments, cutting downtime and preventing belt failure.

Share

PRAB Inc., has introduced the Auto-Take Up system, a conveyor enhancement designed to automatically tighten belts and eliminate the need for manual adjustments.

PRAB designed the Auto-Take Up to monitor tension using load cells on chain conveyors, including steel belt conveyors, drag conveyors, the PRAB ScrapVeyor and others. The Auto-Take Up system is wired to a programmable logic controller (PLC) panel, which monitors tension and automatically tightens the belt to eliminate manual adjustments and downtime. PRAB says the panel can be added to new conveyors or retrofitted onto existing models. If retrofitted onto an existing conveyor, the system can also be operated using that conveyor’s original control panel. Automatic adjustments can be scheduled during low production times or shift changes.

Related Content

-

The Four Phases of a Manufacturer’s Automation Evolution

With more and more automation options available for manufacturers, how do shops figure out what works best? Medical manufacturer rms Company has acquired robot arms, AGVs, pallet changers and software, and while it has found success with all, it has learned how some solutions meet its particular needs better than others.

-

Addressing Manufacturing Challenges with Automation

GrayMatter Robotics’ Physical AI robotic cells for manufacturing offer immediate impact and results.

-

Embracing Automation: Strategies for Small to Medium-Sized Machine Shops

Business drivers for automating to help navigate workforce challenges and boost profitability.