United Grinding Offers Compact, Automated Parts Loading

The Studer RoboLoad saves shop floor space while offering room for workpieces to be manually loaded on six trays within a small work area.

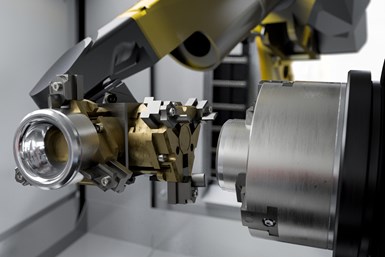

United Grinding’s new Studer RoboLoad system is said to offer manufacturers seamless part-loading automation for CNC radius internal grinding machines such as the company’s Studer S121, S131 and S141. The new Studer loader is said to have a small footprint.

On the Studer S121, S131, and S141 machines – often used to produce dies for the packaging industry – automatic B-axes swivel in a range from -60° to +91°. According to Daniel Schafroth, systems division manager at Studer, this is why any automation must be able to exit the machine and give the B-axis the freedom to swivel — a capability that the Studer RoboLoad offers.

As an external loader, Studer RoboLoad measures 59.06" (1.50 m) wide: half the width of the machine itself. This saves shop floor space while offering room for workpieces to be manually loaded on six trays – each measuring 42.52" × 12.6" (1080 mm × 320 mm) – within a small work area.

“We are not talking about large-scale production, but instead unmanned production during the night shift, for example, or making optimum use of breaks in other production processes,” explains Schafroth. Operators can bring up any grinding program for the workpieces, and the Studer RoboLoad processes them and places each workpiece back in the same place after machining.

For simplicity of operation, the Studer RoboLoad incorporates a setup wizard developed by automation specialists from Wenger of Winterthur, Switzerland. It is said to require no programming knowledge on the part of the setter or machine operator.

Related Content

-

4 Steps to a Cobot Culture: How Thyssenkrupp Bilstein Has Answered Staffing Shortages With Economical Automation

Safe, economical automation using collaborative robots can transform a manufacturing facility and overcome staffing shortfalls, but it takes additional investment and a systemized approach to automation in order to realize this change.

-

Weiler to Debut New Automation Features For Its Lathes

Weiler’s V 110 four-way precision lathe introduces features new to the U.S.

-

Fearless Five-Axis Programming Fosters Shop Growth

Reinvestment in automation has spurred KCS Advanced Machining Service’s growth from prototyping to low-and mid-volume parts. The key to its success? A young staff of talented programmers.

.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)