February 2015 Product Spotlight Slideshow: Grinding

Click through this slideshow for a sampling of grinding equipment, ranging from hand tools and abrasives to complete grinding systems.

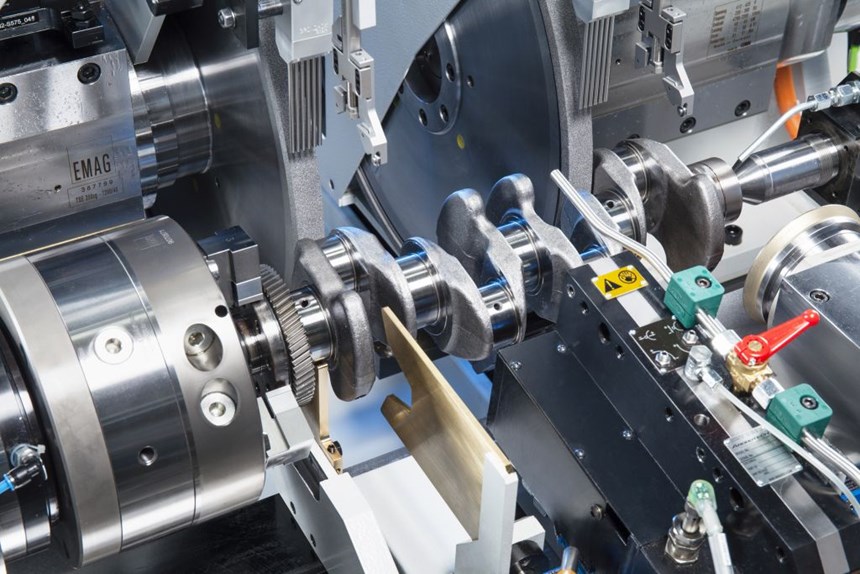

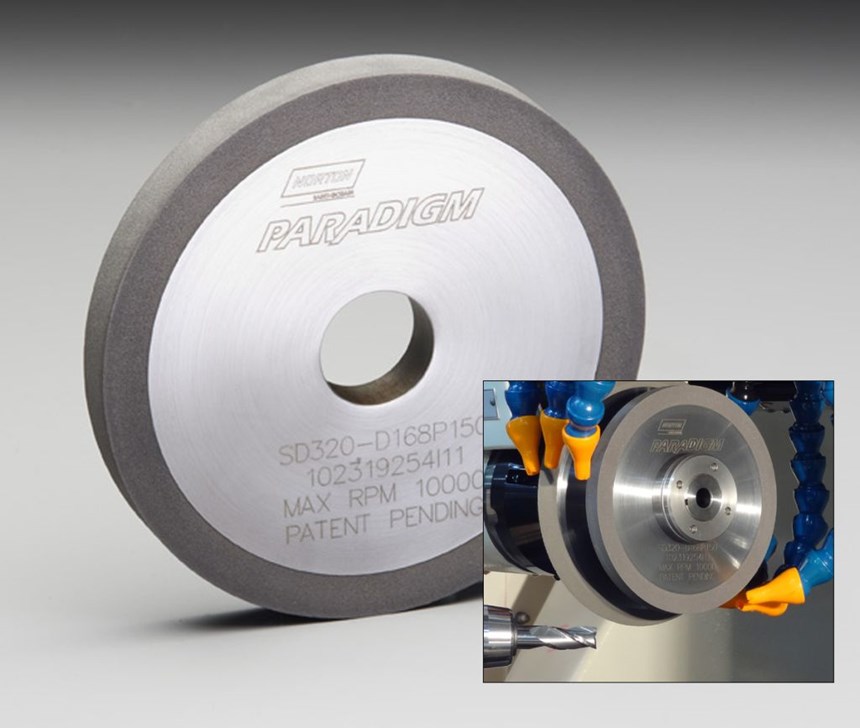

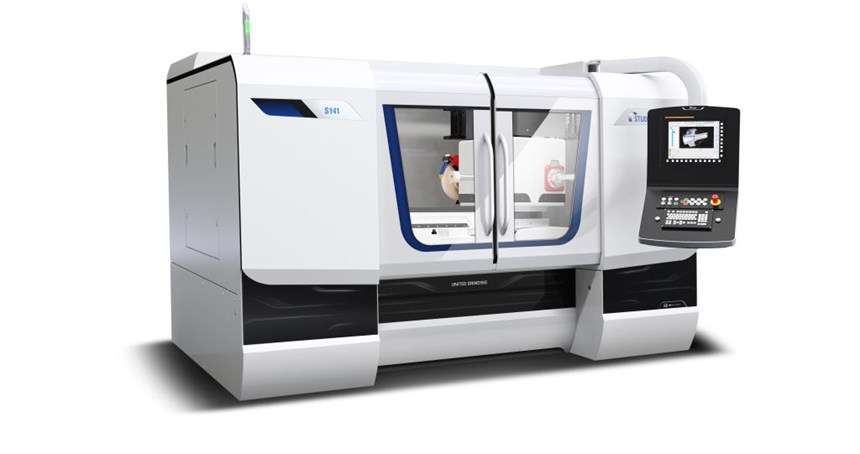

The Modern Equipment Review Spotlight in Modern Machine Shop’s February issue focuses on equipment used for grinding—a versatile process that relies on abrasive media to remove material. The slideshow below highlights a selection of grinding technologies, ranging from ID grinding machines for large parts down to the abrasive wheels used at the cutting edge. Visit the Grinding Zone for case studies, application stories and additional products.

Related Content

-

Inside an Amish-Owned Family Machine Shop

Modern Machine Shop took an exclusive behind-the-scenes tour of an Amish-owned machine shop, where advanced machining technologies work alongside old-world traditions.

-

How to Start a Swiss Machining Department From Scratch

When Shamrock Precision needed to cut production time of its bread-and-butter parts in half, it turned to a new type of machine tool and a new CAM system. Here’s how the company succeeded, despite the newness of it all.

-

Threading On A Lathe

The right choices in tooling and technique can optimize the thread turning process.

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)