Die/Mold

Magnetic Holding Pattern

In finding a way to allow magnetic milling chucks to hold parts that typically aren’t secured by the "invisible" workholding method, this shop happened upon a means to repeatedly position parts in any of its machine tools.

Read MoreThe Mold Consultant

This mold maker saves customers time and money by getting involved early in the design of molded parts.

Read MoreIncremental Automation Pays Dividends

While successful mold makers agree that automation is necessary to remain competitive, they often have different opinions about how to integrate automation. This mold maker does it in gradual phases, and in doing so, it drives shopfloor workers to roles of greater responsibility.

Read MoreWho's Afraid To Cut To Zero?

Most U.S. mold shops still leave extra stock on the cores and cavities of the molds they machine. This practice is unnecessary and wasteful, say proponents of advanced machining technology.

Read MoreMold Machining On The Move

Rethinking the mold machining process leads to concepts worth considering, even for applications outside mold making.

Read MoreMold Machining And Beyond

Adopting high speed machining entailed some surprises. One of the surprises was an unforeseen opportunity for new work.

Read MoreSpeeding To Success

Using a company-wide mantra of faster, faster, faster, some innovative processing techniques and a rationalized deployment of personnel, this Detroit mold maker is snatching success from the jaws of competition.

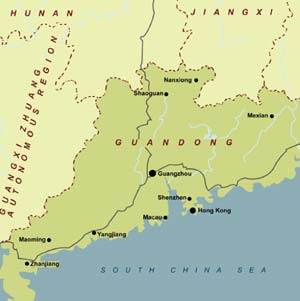

Read MoreChinese Competition In Die/Mold

For several years, the buzz among American moldmakers has included the persistent complaint that competition from China and other Asian nations is eroding business conditions.

Read MoreAutomating The Mold Shop

This shop produces dies and molds around the clock 7 days a week, yet most of the time no one is there.

Read MoreHigh Speed Spindle Helps Mold Maker Stay Ahead

In the competitive arena of moldmaking, shops must produce molds quickly and within tolerance to remain profitable and attract new business. Technological advances in high speed spindles, sophisticated programming methods and high-performance cutting tools allow shops to save time and improve accuracy.

Read More