Top Shops Profile: C&M Machining

C&M Machining was the 2016 Top Shops Honors Program winner in the category of business strategies.

Share

C&M Machining is 2016’s Top Shops Honors Program winner in the business strategies category, given attributes such as its high profit margin, growth rate and quote-to-book ratio compared to other shops.

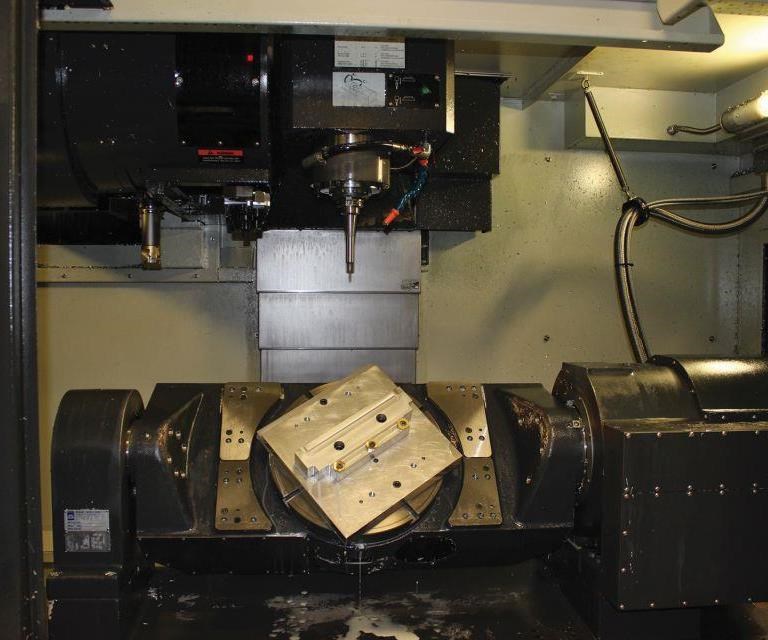

The 100 percent woman-owned shop was founded in 2005 by Cheryl K. Miller with a vision of becoming a leading CNC precision machine shop providing competitively priced, accurately machined components to the aerospace industry. In fact, 99 percent of the company’s sales comes from the aerospace industry in job orders ranging from single prototypes to millions of parts. C&M Machining is an AS9100-certified manufacturing company specializing in interior and structural components and assemblies for aerospace, defense and outer space applications.

End Markets Served

- Aerospace

- Defense

Workpiece Materials Commonly Machined

- Aluminum alloys

- Brass

- Bronze

- Plastics

- Tool steel

- Steel alloys

- Titanium

Related Content

-

Positioned to Prevail: Designing Processes Around People

Stecker Machine Company shows that getting the most value from employees means valuing your employees.

-

Same Headcount, Double the Sales: Successful Job Shop Automation

Doubling sales requires more than just robots. Pro Products’ staff works in tandem with robots, performing inspection and other value-added activities.

-

Finding Skilled Labor Through Partnerships and Benefits

To combat the skilled labor shortage, this Top Shops honoree turned to partnerships and unique benefits to attract talented workers.

Related Content

Positioned to Prevail: Designing Processes Around People

Stecker Machine Company shows that getting the most value from employees means valuing your employees.

Read MoreSame Headcount, Double the Sales: Successful Job Shop Automation

Doubling sales requires more than just robots. Pro Products’ staff works in tandem with robots, performing inspection and other value-added activities.

Read MoreFinding Skilled Labor Through Partnerships and Benefits

To combat the skilled labor shortage, this Top Shops honoree turned to partnerships and unique benefits to attract talented workers.

Read MoreBenchmarking: An Invaluable Business Tool

Modern Machine Shop’s Top Shops program shows shops their strengths and opportunities for improvement, and provides recognition for high-performing businesses.

Read MoreRead Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreObscure CNC Features That Can Help (or Hurt) You

You cannot begin to take advantage of an available feature if you do not know it exists. Conversely, you will not know how to avoid CNC features that may be detrimental to your process.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)