Cutting Tools

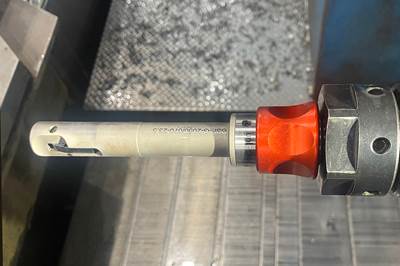

Seco Tools' Reamers Optimize Chip Evacuation

The Nanojet solid-carbide reamers are designed to stop chip jamming and enhance application stability.

Read MoreEmuge-Franken Threading Tools Mill Challenging Materials

The company has expanded its offerings of solid-carbide thread mills with new products for challenging applications.

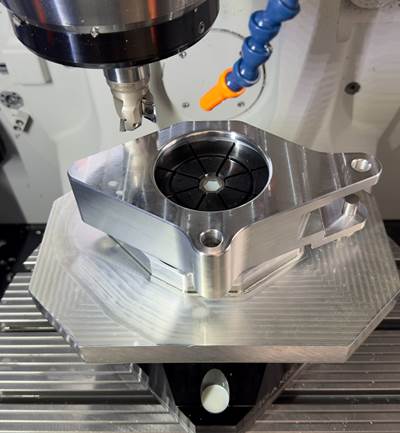

Read MoreShoulder Milling Cuts Racing Part's Cycle Time By Over 50%

Pairing a shoulder mill with a five-axis machine has cut costs and cycle times for one of TTI Machine’s parts, enabling it to support a niche racing community.

Read MoreSandvik Coromant Parting Tool Provides Improved Surface Quality

CoroCut QD Y-axis parting tools feature upgraded blades with no Y offset, providing easier programming and increased stroke.

Read MoreHeule Tool Enables Spot Facing of Difficult-to-Reach Areas

The manually actuated bkac spot facing tool is well suited for large boring mills and other open-air machines.

Read MoreWalter Surface Technologies Ceramic Tools Enhance Product Life

Walter’s Smart Resin Technology is designed to achieve a productive balance between sharpness and tool life in a metalworker’s given application.

Read MoreUnisig Gundrill Production Cells Boost Precision, Output

The R-4-2-2 production cell uses a smart conveyor to simultaneously load four barrel blanks into a UNI four-spindle gundrilling machine.

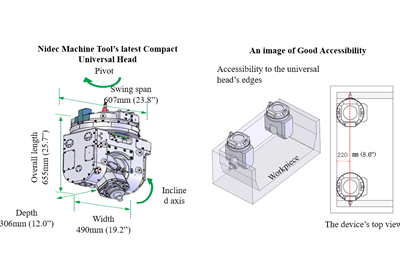

Read MoreNidec Universal Head Enables Versatile Machining

The compact universal head enables better accessibility between the tool and the workpiece, as well as improved surface-finish quality, greater motion range and high-efficiency machining under ideal machining conditions.

Read MoreKyocera SGS Through-Coolant End Mills Improve Chip Evacuation

H-Carb end mills feature a specialized core and flute design improve rigidity and chip flow while reducing deflection.

Read MoreBig Daishowa Milling Cutters Provide Versatile Operation

The company has expanded its lineup of Fullcut Mill FCM tools to include larger diameters and additional lengths.

Read More

.png;maxWidth=300;quality=90)

.png;maxWidth=970;quality=90)