Cutting Tools

Ceratizit's Control System Increases Process Security

Eastec 2023: The ToolScope monitoring and control system can reduce cycle times up to 15% and, with wear monitoring, optimize tool life and provide additional tool reserve usage up to 30%.

Read MoreTungaloy's Mini Boring Bar Tools Machine Small Parts

The TinyMiniTurn line features a full range of solid carbide mini boring bars that enables machining from as small as 0.6 mm (.024″) diameters.

Read MoreSandvik Coromant Turning Tools Enable Y-Axis Turning

The company has developed two new tools to support Y-axis turning: CoroTurn Prime and the CoroPlex YT twin-tool.

Read MoreEmuge-Franken's New Drill Geometry Optimizes Chipbreaking

PunchDrill features patent-pending geometry with a chipbreaker that produces short chips to control machining forces.

Read MoreAllied Machine and Engineering Offers New Sizes of Thread Milling Tools

The AccuThread T3 thread mill line is now available in larger UN and ISO sizes up to 1"-8" and M24 × 3.0.

Read MoreGreenleaf Solid Ceramic End Mills Maximize Material Removal

Eastec 2023: Xsytin-360 end mills feature a four-flute design designed to minimize cutting forces, reduce vibrations and optimize tool life.

Read MoreEmuge-Franken Solid Carbide Drills Withstand Shock, Chipping

The MultiDrill’s TiAlN-T63 coating uses nano-layer technology with surface hardness, providing reduced friction at high temperatures.

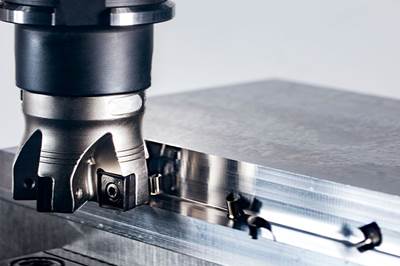

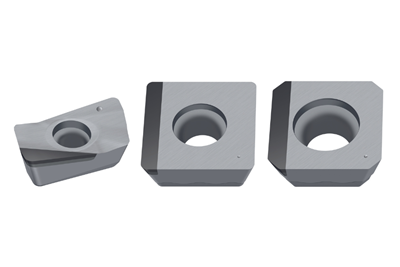

Read MoreWalter Milling Inserts Feature PCD Cutting Edges

The PCD inserts are suitable for milling a variety of nonferrous workpiece materials, such as aluminum, aluminum-silicon alloys, magnesium, magnesium-based alloys, plastics and fiber-reinforced plastics.

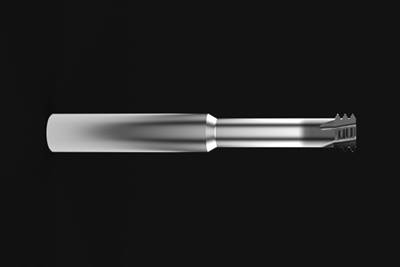

Read MoreSelecting a Thread Mill That Matches Your Needs

Threading tools with the flexibility to thread a broad variety of holes provide the agility many shops need to stay competitive. They may be the only solution for many difficult materials.

WatchSandvik Cormant's End Mills Eliminate Machining Chatter

The company’s CoroMill Dura line of solid end mills has been extended with aluminum-specific tools.

Read More

.png;maxWidth=300;quality=90)