Turning Tools

Lathe Tool Adapter Uses Polygonal Drive for Stability, Faster Setup

Heimatec Inc. offers its U-tec flexible tool adapter system, which enables a standard ER-output live tool to accept various adapters for different applications.

Read MoreTools for Swiss-Type Machining Reduce Setup Time

Iscar offers its SwissCut Innoval product line, a generation of Swiss tools and inserts designed to enable greater accuracy and improved surface finish.

Read MoreGrooving and Turning Tool Features Side-Clamping Mechanism

Iscar’s GEHSR/L-SL tool family for Swiss-type and screw machines are an improved version of its current GEHSR/L screw-clamped tools.

Read MoreBlade-Style Tooling for Internal Grooving

ThinBit, manufactured by Kaiser Tool Co., is expanding its line of DeepGroove support blade-style tooling.

Read MoreISO 13399—A Key Step Toward Data-Driven Manufacturing

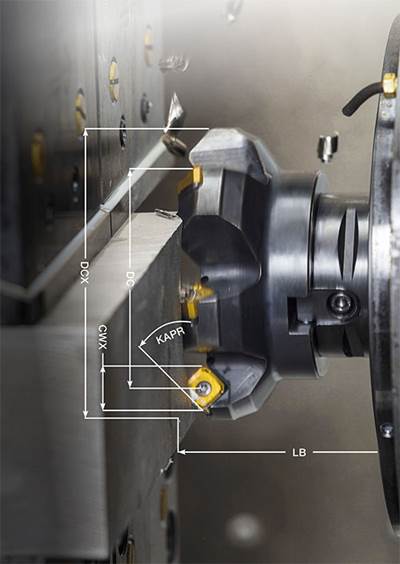

Decisions about the cutting tools used in machining operations are arguably among the most important in modern manufacturing.

Read MoreSecond Chances for Surplus Tools

A new website aims to give shops with excess tooling a way to sell that tooling to other shops. Cutting tool suppliers are using the site for their own excess tools.

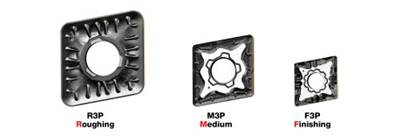

Read MoreChipformers Improve Surface Finish in Turning Applications

Iscar introduces three new chipformers for finishing medium and rough turning of steel: the F3P, M3P and R3P.

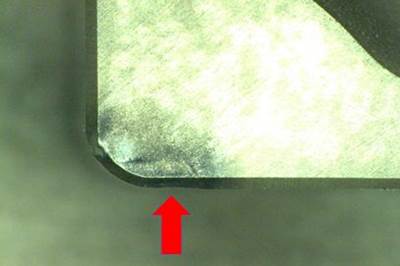

Read MoreCenterline Issues for Turning Inserts

Tooling experts Mike Fagan and David Grant suspect that many programmers and machinists could use a refresher on the importance and effects of insert alignment in turning operations. This short, amply-illustrated paper is their effort to clear up some of the misunderstanding.

Read MoreVideo Highlights Extreme Part-Off Demos

The strength of a tough part-off tool is shown in video showing it parting off a railroad rail and sledgehammer head. Talk about significant interrupted cuts…

WatchAn Extreme Part-Off Demo Returns to IMTS 2014

The strength of part-off tools is shown in demonstrations whereby they part off a railroad rail and sledge hammer head. Talk about significant interrupted cuts…

Watch

.png;maxWidth=300;quality=90)