A Novel Modular Clamping System

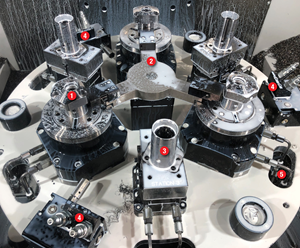

This clamping system minimizes setup times, enable a machine to access five sides of a part and provides highly repeatable positioning for bulky components.

Share

Sometimes, a shop’s efforts to become more effective at machining results in a marketable product line. This was the case with FCS Moulds, now Elmann S.R.L.U.

The Italian moldmaker sought to develop a standard means of fixturing mold components that would minimize setup times, enable its machines to access five sides of a fixtured part, and provide highly repeatable positioning so parts could be removed and accurately refixtured at the same zero reference points as needed. Ultimately, its goal was to increase its machines’ spindle utilization so it could be more competitive with foreign moldmakers.

The FCS modular clamping system was invented by the company’s Almerino Canuto in 2003. After successfully applying this system for its own use, the company formed FCS System to offer the solution to other shops hoping to realize similar benefits. FCS has been available in the United States for a few years through Single Source Technologies (Auburn Hills, Michigan), its exclusive U.S. distributor. Darrell Johnson, SST product manager—milling consumables, says shops that use FCS have sped production time by an average of 88 percent. This workholding solution is particularly helpful for shops machining large mold components as well as other big, unwieldy parts that are commonly tough to set up, such as those used in the fracking industry.

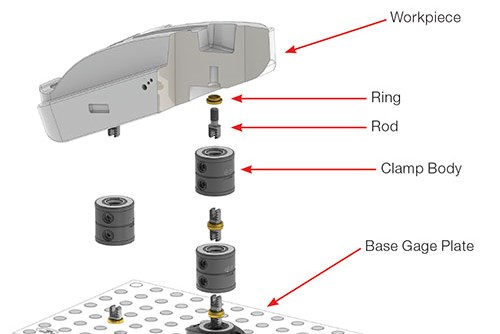

The foundation of FCS is a base gage plate that mounts on a machine’s table. This plate has a grid of threaded holes spaced 50 mm apart to within 5 microns of each other. The other primary components are shown in the image to the left. Mr. Johnson says the system’s rings are key to achieving micron-level positioning repeatability. One side of the TiN-coated steel rings installs into a mating profile machined into the workpiece, achieving an H7-class fit. The other side of the ring has a precision-ground taper that fits into a cylindrical clamping body.

A rod connects the clamping body to the workpiece. One end of the rod installs into the workpiece with standard metric threads, typically M12 × 1.75 or M16 × 2.0. The serrated feature on the other end of the rod fits into the clamping body and draws in the workpiece when tightened, guiding the taper on the ring between them into its precise location.

Mr. Johnson says shops oftentimes start small when first implementing FCS into their processes. This is why SST has developed a basic package that includes select key elements such as a base gage plate and adjustable clamp bodies (with rods and rings), which are available in lengths of 40, 80 and 120 mm. SST also can work with shops to help devise fixturing solutions for their specific applications.

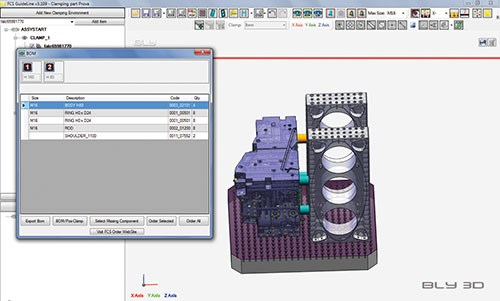

On the other hand, Mr. Johnson says advanced adopters of this workholding method take advantage of the optional Guideline software, another distinguishing element of this workholding approach. Developed by Italy’s BKC, Guideline software enables users to create an appropriate workholding system based on a CAD model of the part to be machined and models of standard FCS fixturing components. The software analyzes the workpiece model and automatically determines appropriate fixturing points while checking for possible interferences with other holes. The software can also automatically generate a bill of materials for the individual FCS workholding elements needed for the application.

Related Content

Navigating Large-Scale CNC Machining: Suburban Tool’s Niche Strategy to Stay Competitive

Facing increasing competition from lower-cost imports, Suburban Tool made a move toward large-scale, in-house machining. By identifying a niche in large, precision angle plates and tombstones, the company has strengthened its ability to control quality and protect its reputation.

Read MoreRevolutionizing Production: How Smart Hydraulics Drive 24/7 Manufacturing Excellence

All World Machinery Supply helps a firearms manufacturer up its game and improve and increase output.

Read MoreMachining Vektek Hydraulic Swing Clamp Bodies Using Royal Products Collet Fixtures

A study in repeatable and flexible workholding by one OEM for another.

Read MoreSMW Autoblok Clamping System Automates Jaw Changes

The KNCS-matic system enables automatic quick jaw change by a conventional industrial robot, which releases the base jaws with a release pin, replaces them and then fixes the next jaws with the pin.

Read More