Biomedical Devices Drive Machining Processes To New Lows

Ultraviolet laser machining technology helps this shop stay on top of shrinking feature and hole sizes common to the latest biomedical components.

The definition of "medical machining" may lack pinpoint precision, but the broad-brush manufacturing sector does offer opportunities for machine shops beyond the production of implant devices and bone screws. Biotechnology is one example—and it is an industry segment that is burgeoning. In many cases, though, the exotic materials and micron-level features common to the latest biomedical devices present machining challenges that physical milling and drilling often cannot surmount. One non-traditional machining process that has proven effective and repeatable—and in some cases the only means to machine select biomedical parts—is ultraviolet (UV) laser machining.

Such low-power, short-wavelength laser systems are commonly used by medical OEMs and laser contract shops to produce tricky biomedical components. According to Bill Kallgren, sales manager for J.P. Sercel Associates (JPSA), these laser systems have yet to find a home in what might be considered a "typical" medical contract machine shop, occupying floor space alongside Swiss-type lathes, machining centers or grinding machines. Often the reason for this isn't because those shops lack the cleanliness or environmental control capability (clean room conditions are often required for biomedical processing requirements, not for UV laser machining), but rather it is because of the lack of knowledge in the metalworking community about this particular laser machining process. Those in metalworking circles are more likely to be familiar with high-power CO2 or YAG laser systems used for cutting thin or thick metal sheet.

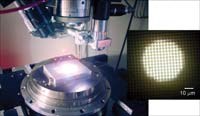

JPSA, located in Hollis, New Hampshire, specializes in laser machining systems that use pulsating zaps of UV laser light to machine small features in materials such as glass, silicon nitride, quartz, polymers, ceramics and sapphire. Not only does the company design and build laser systems, but its R&D applications department, which currently has 13 UV laser systems, doubles as a contract shop. That shop serves a variety of customers in the medical, electronic and semiconductor fields.

No doubt there are enterprising medical contract shops looking for a way to expand their capabilities and customer base, and UV laser machining may be the vehicle to merge into the biomedical market. Shedding light on this technology and how it is applied at JPSA's shop is valuable to those shops and other manufacturers that may be considering alternative machining methods.

New Devices, New Challenges

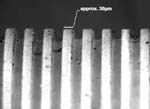

Biomedical devices often function at the cellular level, meaning that their components' holes, channels and other features may be minuscule. The range of hole diameters that JPSA machines is typically between 1 micron and a couple hundred microns. Not surprisingly, hole diameters and relative feature position tolerances are also in the micron range. Though the material thickness often can be no more than 2 mm, hole aspect ratios (ratio of hole length to diameter) are often quite high.

Heat generated during a machining process is the enemy of biomedical materials, most notably those made of polymers and Teflons. That is one of the reasons why physical milling won't cut it for these materials. Because the materials are susceptible to discoloration, melting and burning, any machining operation must not deliver a great deal of heat into the part. UV laser machining is virtually a heat-free process, so material damage likely won't occur.

Laser Types

UV lasers remove material by a process called photo ablation. Successive, high-repetition laser pulses remove tiny, controlled amounts of material. The small amount of ablated material evaporates as a plume of plasma. Depending on the material being processed, toxic gases may be generated which would require an efficient gas collection and scrubber system, such as activated charcoal canisters.

JPSA uses two types of UV laser systems—excimer and diode pumped solid state (DPSS). In simplest terms, the difference between these two lasers boils down to beam diameter (or laser spot size). An excimer laser will produce a larger spot size than a DPSS. While an excimer laser's relatively large beam diameter might seem inappropriate for very small holes and features, this laser spot size can be shaped with a mask, allowing only select portions of the beam to impact the part surface (using laser-speak, this process is called near-field imaging). The mask is shaped per the feature to be machined, and multiple features can be machined at one time. In terms of hole making, this simultaneous processing of multiple holes ensures very accurate hole-to-hole positioning. JPSA makes its own masks from molybdenum for short-run jobs or prototypes. For high-volume jobs in which the mask will experience extended use, a more durable, though more expensive, chrome-on-quartz mask will be used.

Excimer lasers are very effective in producing blind holes. Thanks to a very high pulse-to-pulse stability, excimer lasers can create blind holes or micro-channels to depths and widths accurate to ±3 microns (sub-micron accuracies are possible in some cases). This accurate depth control also enables excimer lasers to produce holes and oval shapes in only one side of a needle, for example. The depth control will allow the laser to cut the hole in one needle sidewall without damaging the metal on the opposing sidewall. It also allows selective material removal, such as stripping a section of plastic from a coated catheter without harming the metal underneath.

Because toxic gases such as fluorine are part of an excimer laser's gas recipe, an effective gas handling protocol is required. For safety reasons, these gases are stored away from the laser system in appropriately ventilated and monitored gas cabinets located outside of the shop, as is the case with JPSA's facility.

DPSS lasers, on the other hand, offer very high repetition rates and typically lower operating costs. Unlike excimer lasers, DPSS lasers focus the light source down to a very small spot size. That, combined with the fact that DPSS lasers operate at a much higher pulse frequency (50,000 Hz compared to an excimer's 400 Hz), makes DPSS lasers more effective in slicing through materials very quickly (as in scribing or cutting patterns). The corner radius for features machined by a DPSS laser will be equal to the laser spot radius, which can be as small as 2.5 microns. For applications where a sharper corner is required, often a masked excimer laser will be used.

The choice of laser type, wavelength and energy density is largely based on material, feature shape and part thickness. In general, shorter wavelengths (such as those available with an excimer laser down to 157 nanometer wavelength) work best for clear materials and Teflon-based materials; longer wavelengths are more suitable for ceramics, metals and certain polymers.

Hole-Making Issues

Burrs are an issue with nearly every physical hole-making process. The "burr" created during UV laser machining might not be able to be felt with a fingernail, but still might affect a biomedical device's performance. During laser machining, the material that is turned into plasma and ejected from the surface quickly cools back into a solid. If not collected by a vacuum source common to these laser systems, this material can recast around the perimeter of the feature being machined. Recast material just a couple of microns tall could be significant for a 25-micron-diameter hole, for example. A protective coating can be applied to the target material to limit this recasting effect. Alternately, recast material can be removed by secondary electro polishing or chemical treatment.

A taper will exist for most any feature machined by a laser. For a typical laser machining process, the taper angle will measure between 4 degrees half-angle to 15 degrees half-angle. A zero-taper hole can be produced by using a complex method of managing laser energy density and continuously changing the beam's focal point (essentially chasing the focal point down the hole), but this is very time consuming and thus very expensive to produce.

Accurate Fixturing

JPSA spends a great deal of time developing accurate fixtures, especially for repeat or high-volume jobs. The objective is to create a pallet part fixture that holds a number of parts such that all loaded parts are aligned with the machine once the fixture is aligned. Pallet fixturing also allows for efficient use of labor. While the laser processes parts, an operator can be loading another fixture. For very high-volume jobs, JPSA uses automated part handling systems to load and unload pallets of parts.

Because part contamination is a big issue with many biomedical parts, fixtures may be coated with Teflon. Some medical customers go so far as to specify a particular type of glove operators must wear while handling parts (latex-free or powder-free gloves, for example). For other customers, this isn't a big issue, because the parts will go through some type of post-process cleaning to remove contaminants. "It is important to work closely with a customer's quality control department so that the correct handling procedures are followed," says Mr. Kallgren.

Do Your Homework

As with the integration of any new technology, there is a learning curve associated with UV laser machining systems. In finding out more about this machining process, it is best to spend time talking to shops currently using lasers to find out what is involved in this alternate machining process in order to level the laser learning curve.

Related Content

Grinding Wheel Safety: Respect The Maximum Speed

One potential source of serious injury in grinding comes from an oversight that is easy to make: operating the wheel in an over-speed condition.

Read MoreBuying a Lathe: The Basics

Lathes represent some of the oldest machining technology, but it’s still helpful to remember the basics when considering the purchase of a new turning machine.

Read MoreHow to Reduce Cycle Times by 70% and More on Your Existing CNCs and Dramatically Improve Tool Life Too

By employing advanced high efficiency milling techniques for the entire machining routine, SolidCAM’s iMachining technology can drastically reduce cycle times while vastly improving tool life compared to traditional milling.

Read MoreHow to Start a Swiss Machining Department From Scratch

When Shamrock Precision needed to cut production time of its bread-and-butter parts in half, it turned to a new type of machine tool and a new CAM system. Here’s how the company succeeded, despite the newness of it all.

Read MoreRead Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More.jpg;maxWidth=970;quality=90)

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)