Share

One of the key benefits of using a horizontal machining center (HMC) is the option to mount workpieces on a tombstone. Multiple workpieces can be mounted per side. Indexing the tombstone on the machine’s rotary table makes another set of workpieces accessible for machining. The more sides on the tombstone, the more sets of parts that can be machined without operator attention or idle time for a pallet change. The productivity gains can be substantial.

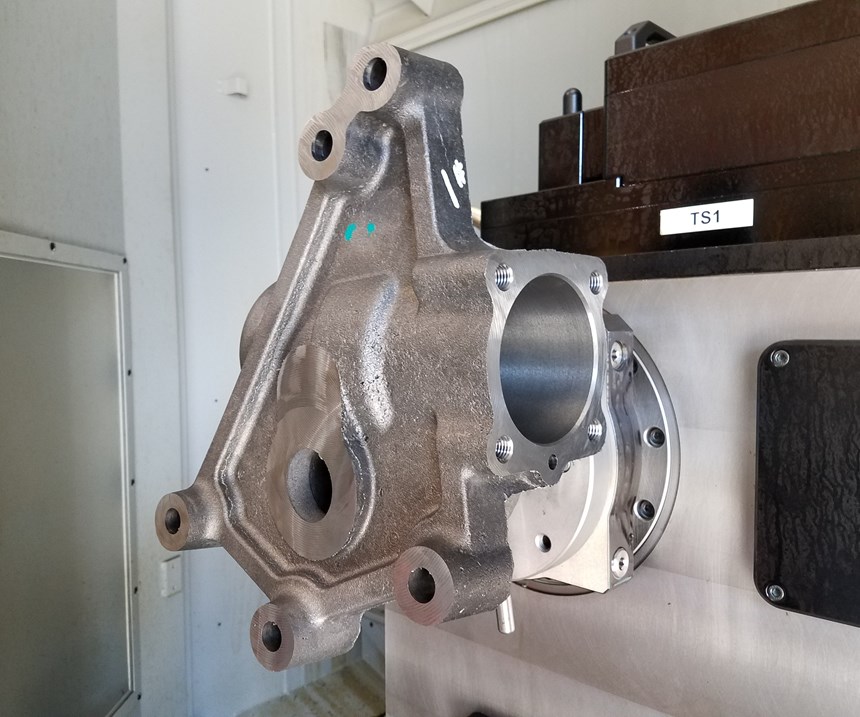

KME CNC (Irvine, California) has added some new twists and turns to this scenario—both literally and figuratively speaking. Literally, new twists and turns are represented by the rotary capabilities of its five-axis tombstones. These tombstones provide programmable rotary platters enabling the HMC to do five-sided machining. The machine’s three linear axes can combine with the coordinated rotary indexing motion of the platters and the rotary motion of the machine’s worktable to reach five sides of each workpiece on the face of the tombstone—and do some operations with all five axes moving at once (of course, the orientation of the cutting tool in the horizontal spindle cannot be programmed, so this is not five-axis machining for contours or sculptured surfaces). These rotary platters add greatly to the flexibility of the HMC’s machining capability, applications manager Jerome Mel says.

Mr. Mel points out that the rotary platters operate independently, so as one piece is being machined on one platter, the next platter in the sequence can be rotating into the starting position so that the cutting tool can move to it and resume machining. There is no delay waiting for the platter to index to the right spot after the tool is at the home point in the part program. Holding multiple parts on each side of the tombstone enables a cutting tool to work all parts before the next tool change, adding to the efficiency of this approach.

Standard KME CNC tombstones, which are only offered in a two-sided model at this time, are equipped with four platters on one side or two platters on both sides. Custom configurations can be arranged for as many as four platters on each side. The indexing platters extend only a couple inches from the face of the tombstone, taking up less space within the HMC’s workzone than surface-mounted units. The servomotors, circuit boards and all power and signal cables are safely housed within the hollow interior of the tombstone. Parts less than 7 inches wide are said to be ideal for the spacing of the platters.

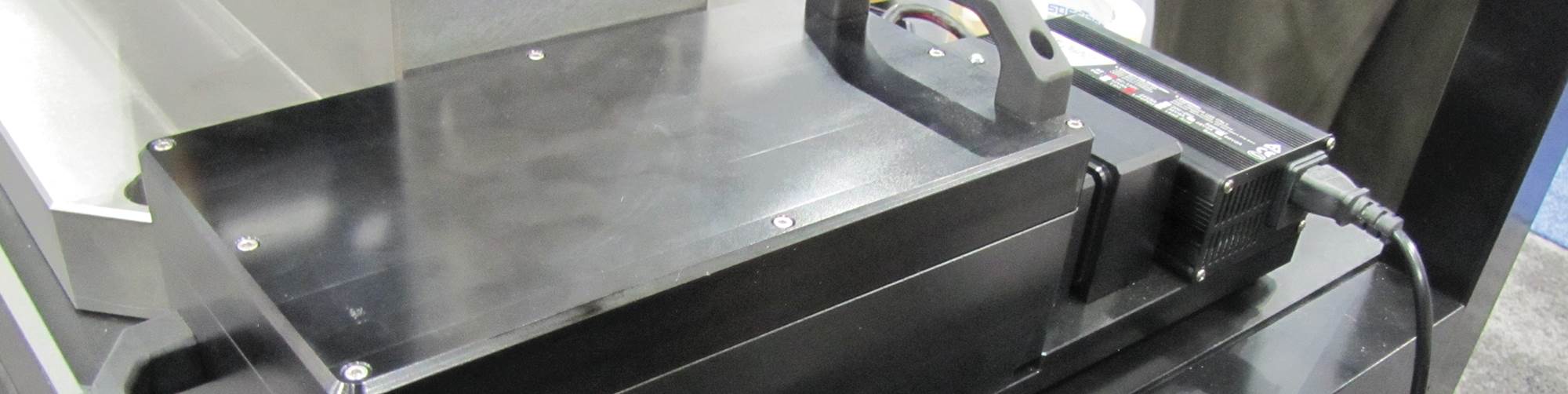

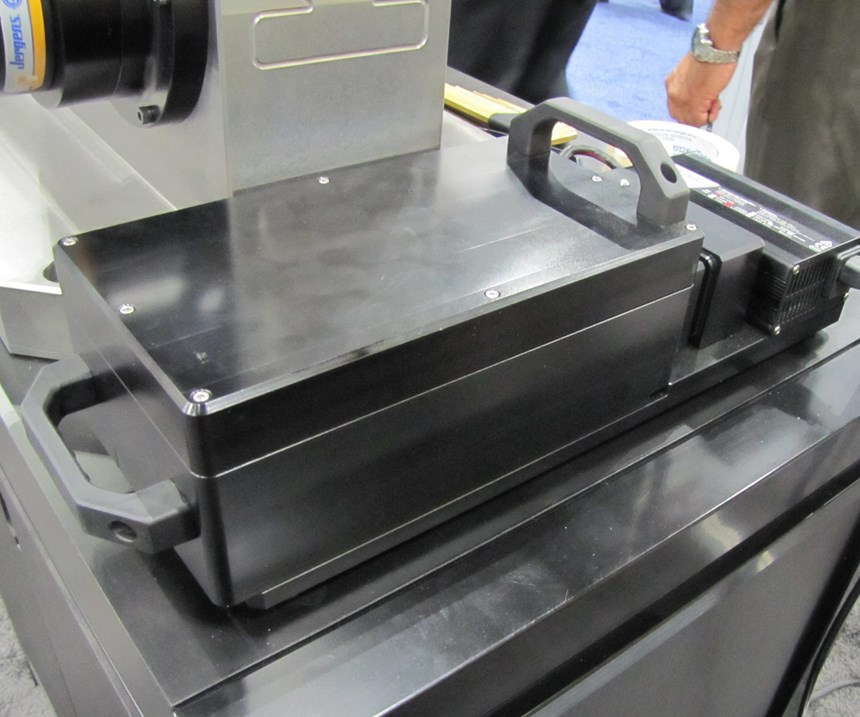

Figuratively speaking, other features add new “twists and turns” to using tombstones on an HMC as well. Specifically, the tombstones operate without electrical cables or communication wires. A rechargeable powercell that slides on and off the top of the tombstone provides the electrical energy to run all the rotary platters. The tombstone needs no connection to the power supply of the host HMC. Meanwhile, a radio frequency (RF) receiver within the tombstone provides the digital connection to a transmitter connected to the machine’s CNC. The tombstone needs no other networking or wiring to receive signals from the CNC to control the servo drives on each platter. Because the tombstones do not have exterior cables or wires, they are free to shuttle in and out on a pallet system. This freedom enhances lights-out operations, especially in an automated machining cell with a pallet pool.

Here are more details about the powercell. It provides as many as eight hours of operation before it needs to be exchanged for a fully charged powercell. Handles on the top and side of the cell can be grasped for its removal. Exchanging the powercells can be accomplished in a few seconds, depending on how the user arranges the exchange station. The depleted powercell can be replenished in about 35 minutes on a recharging station plugged into a 120-volt AC outlet. With the latest lithium-ion technology, the powercell is expected to experience 2,000 charges before its capacity falls below 80 percent of its original potential, Mr. Mel says.

Powercells are rated for 250, 300 or 750 foot-pounds of torque to match the five sizes of tombstone models (base sizes of 250, 300, 400, 500 and 630 mm).

Wire-free communication also has its advantages. According to Mr. Mel, RF communication was chosen because it is resistant to electrical “noise” that can interfere with Wi-Fi or Bluetooth data transmission. Each tombstone has a unique communications address, so only signals with that address can be received. According to Mr. Mel, the tombstones can be integrated with any existing CNC unit. “They all have their own processors, their own memory and their own independent controller to interface with the desired system. You do not need to program the transmitter/receiver module. It works with direct G code from your machine control,” he says. It is possible for each rotary indexer to have its own part program so different parts can be set up on the tombstone at once.

Stated repeatability for the rotary platters is ±5 arcseconds; stated accuracy is ±10 arcseconds. Programmed rotary motions resolve to 0.0018-inch increments.

Related Content

5 Tool Setting Techniques

Each tool setting technique has merit, and it depends on where you are as a shop and the type of work you do, as cost and efficiency all come into play.

Read MoreShoulder Milling Cuts Racing Part's Cycle Time By Over 50%

Pairing a shoulder mill with a five-axis machine has cut costs and cycle times for one of TTI Machine’s parts, enabling it to support a niche racing community.

Read MoreShop Reclaims 10,000 Square Feet with Inventory Management System

Intech Athens’ inventory management system, which includes vertical lift modules from Kardex Remstar and tool management software from ZOLLER, has saved the company time, space and money.

Read More10 Robotic Solutions You Can Find at IMTS 2026

Discover how today’s robots and cobots are making it easier than ever to automate tasks, free up skilled workers, and run machines unattended – even in small and midsized shops.

Read MoreRead Next

OEM Tour Video: Lean Manufacturing for Measurement and Metrology

How can a facility that requires manual work for some long-standing parts be made more efficient? Join us as we look inside The L. S. Starrett Company’s headquarters in Athol, Massachusetts, and see how this long-established OEM is updating its processes.

Read More