Cold Clamping For Small, Delicate Parts

Icing plates use the adhesive power of ice to securely clamp parts of virtually limitless shapes and materials for milling and turning operations.

Rigid clamping is essential to most machining operations, but some parts are extremely difficult to hold securely. Workpiece fragility may be a concern—high clamping forces can distort or damage ceramic, graphite or other brittle materials, for example. Even metal parts may include minute features or thin walls that can buckle under pressure. And regardless of material, components with asymmetrical, complex geometries present their own workholding challenges.

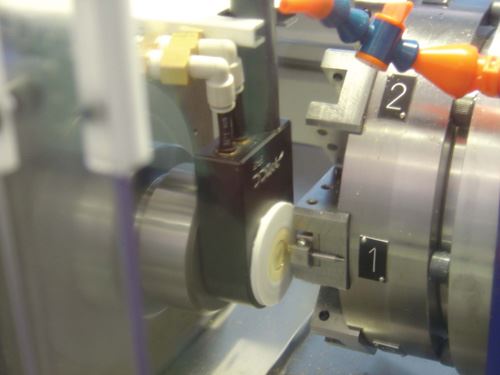

However, traditional clamps, vises and chucks aren’t the only available workholding options. One solution developed by Capens, France-based manufacturer AMCC is said to provide not only rigid, stress-free clamping for virtually any part shape and material, but also ease of use—to operate, just add water. The GF series Icing Plates uses the adhesive power of ice to hold parts for milling, turning, grinding or custom applications. The plates are available in the United States through Coraopolis, Pennsylvania-based distributor Industries Consult Plus.

A compact, mono-block design enables fast installation, the company says. Additionally, no external cooling device is required. Users simply connect the apparatus to a compressed air system, spray water onto the plate and position the part to be machined. Clamping is achieved by activating the device’s temperature-control button, which causes the water on the plate to freeze in as little as 30 seconds. Unclamping is performed just as fast by reversing the plate’s freeze/thaw valve.

Central to the plate’s operation is an internal cooling device that rapidly decompresses pressurized air. Coupled with a heat exchanger, this cools the plate to temperatures as low as -10°C. The system also evacuates heat generated by machining, eliminating the need for coolant. If necessary, lubricants can be brushed or sprayed onto the part surface.

According to the company, the icing plates are most useful for delicate-parts manufacturers in the medical, electronics, watch-making and jewelry industries, among others. They are said to be particularly effective for machining sintered parts, unfired ceramics, ferrite, graphite and other brittle materials because there are no clamping forces that can cause damage or distortion. The freezing process amplifies these advantages with plastic and sintered parts, which harden under cold temperatures and are thus less likely to fracture or splinter during the machining process. Similar benefits are realized with composite materials. Moreover, the film of ice between the part and the plate surface is uniform and infinitesimally thin, ensuring consistent Z-axis zero position.

The icing plates eliminate the need for costly custom fixtures for asymmetrical or difficult-to-clamp workpieces because they grip parts by only one face. This also allows cutting tools full access to all other sides of the workpiece. While the plates are most often used to hold materials such as those mentioned above, ice has a adhesion force per unit area than many magnet or vacuum systems when used with metals, the company says.

One of the three available models, the GFR-55, is designed specifically for turning operations with speeds ranging to 6,000 rpm. Its clamping surface measures 2.16 inches in diameter. The other two models, the GF-140 and the GF-250, can be used for milling, grinding, diamond-dressing and other operations. Clamping surfaces on these models measure 5.51 by 3.94 inches and 9.84 by 5.9 inches, respectively. Both the GFR-55 and the GF-140 feature removable icing plates that can be machined as required to suit specific jobs and then disassembled and stored for later use. Typically, users bore recesses into the plates or incorporate locating pins for part positioning, the company says.

An optional “Z-reference non-freeze key” ensures that the plate itself can be used for a referencing Z-axis zero position when ice builds up on areas not occupied by the workpiece. Other available options include locating holes for X-Y positioning and steel shims for securing the device to magnetic grinder plates.

Related Content

Shop Doubles Sales with High-Mix, Low-Volume Automation

Robots with adaptive grippers have opened entire shifts of capacity to high-mix, low-volume shop Précinov, doubling its sales.

Read MoreParts and Programs: Setup for Success

Tips for program and work setups that can simplify adjustments and troubleshooting.

Read MoreSimple Workholding for Robotic Automation

Robotic automation relies on reliable workholding, and these modular pneumatic jaws make it simple.

Read MoreLean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

Read MoreRead Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More

.png;maxWidth=300;quality=90)