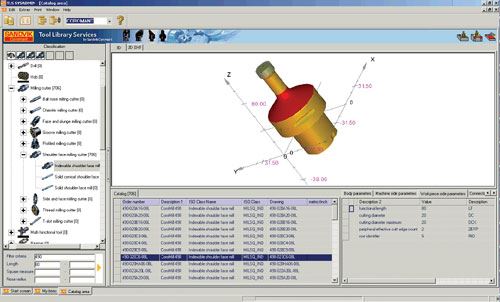

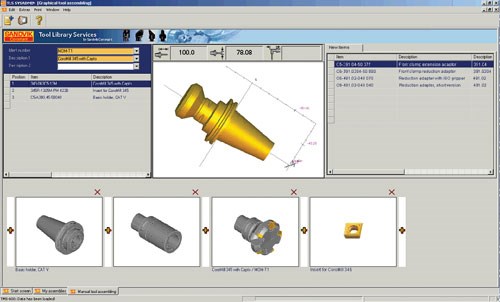

Coming Soon: Universal, CAM-Independent Cutting Tool Library

Software relying on the ISO standards for cutting tools aims to dramatically simplify tool selection.

ISO 13399 is a family of standards that defines dimensions and other data for cutting tools, inserts, tool bodies, adapters, toolholders and other tooling-related components. In theory, these standards enable cutting tool items from various vendors to be described precisely within a single framework. In practice, what is the value of this consistency?

Related Content

Threading On A Lathe

The right choices in tooling and technique can optimize the thread turning process.

Read MoreChoosing Your Carbide Grade: A Guide

Without an international standard for designating carbide grades or application ranges, users must rely on relative judgments and background knowledge for success.

Read MoreHow to Turn Machine Shop Downtime Into Process Expertise

To take advantage of a lull in business, JR Machine devised a week-long cutting tool event that elevated the shop’s capabilities with aerospace alloys.

Read MoreTwin Spindle Design Doubles Production of Small Parts

After experiencing process stalls in the finishing stage of production, Bryan Machine Service designed an air-powered twin spindle and indexable rotating base to effectively double its production of small parts.

Read MoreRead Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)