Choosing Your Carbide Grade: A Guide

Without an international standard for designating carbide grades or application ranges, users must rely on relative judgments and background knowledge for success.

Share

While the metallurgic term “carbide grades” refers specifically to tungsten carbide (WC) sintered with cobalt, the same term has a broader meaning in machining: sintered tungsten carbide combined with coatings and other treatments. For example, two turning inserts made of the same carbide material but with a different coating or post-treatment are considered different grades. Carbide and coating combinations lack classification standardization, however, so different cutting tool suppliers use different names and classification methods for their grade charts. This can make grade comparison difficult for the end-user, an especially trying problem given that carbide grade suitability for a given application dramatically affects possible cutting conditions and tool life.

To navigate this maze, users must first understand what constitutes a carbide grade and how each element influences different aspects of machining.

What is the Substrate?

The substrate is the bare material of the cutting insert or solid tool underneath the coatings and post-treatments. It is typically made up of between 80- and 95-percent WC. To give the substrate the desired properties, material manufacturers add various alloying elements. The main alloying element is cobalt (Co) — higher levels of cobalt lead to greater toughness, while lower levels of cobalt lead to greater hardness. Very hard substrates can reach a hardness of 1800 HV and provide excellent wear resistance, but are very brittle and are only suitable for very stable conditions. Very tough substrates have a hardness of around 1300 HV. These substrates can machine only at lower cutting speeds and wear out faster, but have better resistance to interrupted cuts and unfavorable conditions.

The right balance between hardness and toughness is the most crucial factor when selecting a grade for a particular application. Picking a grade that is too hard can lead to micro breakages along the cutting edge or even catastrophic failure. At the same time, a grade that is too tough will wear out fast or require decreasing the cutting speed, thus reducing productivity. Table 1 provides some basic guidelines for selecting the correct hardness:

| Material | Turning | Milling | ||

|---|---|---|---|---|

| Continuous | Light Interrupted | Heavy Interrupted | ||

| Steel | Hard | Medium | Tough | Tough |

| Stainless Steel | Hard | Medium | Tough | Tough |

| Aluminum | Hard | Medium-Hard | Medium | Medium |

| Inconel | Very Hard | Hard | Medium | Tough |

| Titanium | Very Hard | Hard | Medium | Medium |

What Are Carbide Coatings?

Most modern carbide inserts and solid carbide tools are coated with a thin film (between 3 and 20 microns, or 0.0001 to 0.0007 inch). The coating is typically composed of titanium nitride, aluminum oxide and titanium carbon nitride layers. This coating increases the hardness and creates a heat barrier between the cut and the substrate.

Cutting tool coatings are added through one of two major technologies:

- CVD (Chemical Vapor Deposition) —CVD coating layers can be as thick as 25 microns. This thickness ensures an effective heat barrier and enables higher cutting speeds compared with PVD coatings. On the other hand, that same thickness makes coating very sharp cutting edges impossible, and the coating is more prone to cracks and breakages.

- PVD (Physical Vapor Deposition) — PVD coatings range in thickness from 1 to 8 microns. PVD-coated inserts need to operate at lower cutting speeds when compared with CVD; however, they are tougher, can be applied on sharp cutting edges, and have smoother surfaces that generate less friction.

Table 2 provides a basic guide to selecting the most suitable coating for different applications.

| Material | Turning | Parting and Grooving | Milling | |

|---|---|---|---|---|

| High Cutting Speed | Low Cutting Speed | |||

| Steel | CVD | PVD | PVD | PVD / Thin CVD |

| Stainless Steel | Thin CVD | PVD | PVD | PVD / Thin CVD |

| Aluminum | Uncoated | Uncoated | Uncoated | Uncoated |

| Inconel | Thin PVD | Thin PVD | Thin PVD | PVD |

| Titanium | Thin PVD / Uncoated | Thin PVD / Uncoated | Thin PVD / Uncoated | PVD / Uncoated |

What Are Post-Treatments?

Despite only gaining traction about a decade ago, adding a post-treatment after coating has become an industry standard. These treatments are usually sandblasting or other polishing techniques that smoothen the top coating layer, reducing friction and, as a result, generated heat. Price differences are typically minor, and in most cases, it is recommended to favor grades with post-treatment.

Grade Selection Charts

To choose the correct carbide grade for a particular application, look at the supplier's catalog or website for guidance. Although there is no formal international standard, most suppliers use charts that describe grades’ recommended working envelopes based on their "application range" as expressed in a three-character letter-number combination, such as P05-P20.

The first letter represents the material group according to the ISO standard. A letter and a corresponding color are assigned to each material group.

| Letter | Material | Color |

| P | Steel | Blue |

| M | Stainless Steel | Yellow |

| K | Cast Iron | Red |

| N | Non-Ferrous | Green |

| S | Super-Alloys | Orange |

| H | Hardened Steel | Grey |

The following two numbers represent the grade's relative hardness level on a scale from 05 to 45 in increments of 5. A 05 application requires a very hard grade suitable for favorable and stable conditions. A 45 application requires a very tough grade suitable for unfavorable and unstable conditions.

Again, there is no standard for these values, so they should be interpreted as a relative value within the specific grade table in which they appear. For example, a grade marked as P10-P20 in two catalogs of different suppliers could have a different hardness.

Grade selection tables are usually shown separately for four different main applications:

- Turning

- Milling

- Grooving/Parting

- Drilling

A grade marked as P10-P20 in the turning grades table could have different hardness than a grade marked as P10-P20 in the milling grades table, even in the same catalog. This difference comes down to the fact that favorable conditions vary across different applications. Turning applications are best tackled with very hard grades, but in milling, favorable conditions require some toughness because of its interrupted nature.

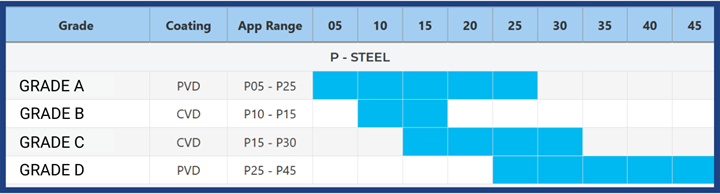

Table 3, “Grades for Turning” - Source: MachiningDoctor.com

Table 3 depicts a hypothetical chart of grades and their uses in different difficulties of turning applications, as might appear in a cutting tools supplier catalog. In this example, grade A would be recommended for a wide range of turning conditions, but not for heavy interrupted cuts, while grade D would be recommended for heavy interrupted turning and other highly unfavorable conditions. Tools such as the Grades Finder from MachiningDoctor.com can search for grades according to this designation system.

Carbide Grade Designations

Just as there is no official standard for grade application ranges, there is no formal standard for grade designations. That said, most major carbide insert suppliers follow common guidelines in their grade designations. The "classic" designation follows a six-character format BBSSNN, where:

- BB — Brand Code: Each major supplier has its own letters associated with it.

- SS — Grade Series Number: Grade series numbers are usually represented by two random digits. A series is usually a group of grades designed for a particular raw material and sharing a common coating type. Some examples of grade series could be:

- BB85 — CVD grades for turning steel.

- BB64 — PVD grades for nickel-based alloys.

- BB23 — CVD grades for milling cast iron.

- NN — Hardness Level: The last two digits, in most cases, reflect the hardness level of the different grades in a series. The number usually ranges from 05 to 45 according to the same system explained above about the grade charts. For example:

- BB8505 — A very hard grade for turning steel in stable conditions.

- BB8540 — A very tough grade for turning steel in heavy interrupted cuts.

The above explanation is correct in many cases. But since this is not an ISO/ANSI standard, some suppliers make their own adjustments to the system, and it is wise to be on the lookout for these changes.

Turning Grades

Grades play a vital role in turning applications, more than in any other application. Because of that, when checking any supplier's catalog, the turning section will feature the largest selection of grades.

Why are grades so important in turning?

This extensive range of turning grades stems from the extensive range of turning applications. Everything from continuous machining, where the cutting edge is constantly engaged with the workpiece and suffers no impact but generates lots of heat, to interrupted cuts, which have heavy impacts, falls into this category.

The wide range of turning grades also relates to the vast array of diameters in manufacturing, from 1/8 inch (3 mm) for Swiss-type machines to 100 inches for heavy industrial purposes. Because the cutting speed also depends on the diameter, there is a need for different grades that are optimized for either low or high cutting speeds.

Major suppliers usually provide separate series of grades for each material group. In each series, the grades range from tough for interrupted cuts to hard for continuous machining.

Milling Grades

In milling, the range of grades on offer is smaller. Due to the application’s fundamentally interrupted nature, milling tools require tough grades with high impact resistance. For the same reason, the coating layer must be thin — otherwise, it will not withstand the impacts.

Most suppliers will use a tough substrate and a variety of coatings for milling different material groups.

Parting and Grooving Grades

In parting or grooving applications, grade selection is limited due to cutting speed factors. That is, the diameter gets smaller as the cut approaches the center. The cutting speed thus decreases gradually. In parting-off to the center, the speed ultimately reaches zero at the end of the cut, and the operation becomes shearing instead of cutting.

Therefore, a grade for parting-off must be compatible with a wide range of cutting speeds, and the substrate should be tough enough to handle the shearing at the end of the operation.

Shallow grooving is an exception to other types. As it shares similarities with turning, suppliers with a large selection of grooving inserts will usually offer a wider variety of grades for specific material groups and conditions.

Drilling Grades

In drilling, the center of the drill always has a cutting speed of zero, while the periphery has a cutting speed that depends on the drill diameter and spindle speed. Grades optimized for high cutting speeds will fail, and therefore should not be used. Most suppliers will offer just a handful of grades.

Related Content

Walter Ceramic Inserts Enable Efficient Turning, Milling

Suitable turning and milling applications of the WIS30 ceramic grade include roughing, semi-finishing and finishing, as well as interrupted cuts.

Read MoreThe Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

Read MoreUnderstanding Process Damping in Milling Operations

Despite the advances in modeling machining operations over the past decades, process damping remains a topic of interest, including new tool designs that increase the effect.

Read MoreRead Next

OEM Tour Video: Lean Manufacturing for Measurement and Metrology

How can a facility that requires manual work for some long-standing parts be made more efficient? Join us as we look inside The L. S. Starrett Company’s headquarters in Athol, Massachusetts, and see how this long-established OEM is updating its processes.

Read More